Digital Twins for Agility in Car Body Stamping

NIO ES6 body side panel digital twin simulated by AutoForm software; source: internet by courtesy of NIO

Over the past months, several carmakers announced aggressive cost cutting initiatives to brace for the volatile market and allocate sufficient resources to emerging technologies. Is now the time to overcome organizational friction and capture the untapped potential of digital transformation? Automotive companies have been transforming into Agile enterprises in sales and software development. This article explores how a physics-driven Digital Twin enables Agility in the traditional discipline of car body stamping. Read how to generate ROI by eliminating waste and increasing speed and reliability in this volatile environment.

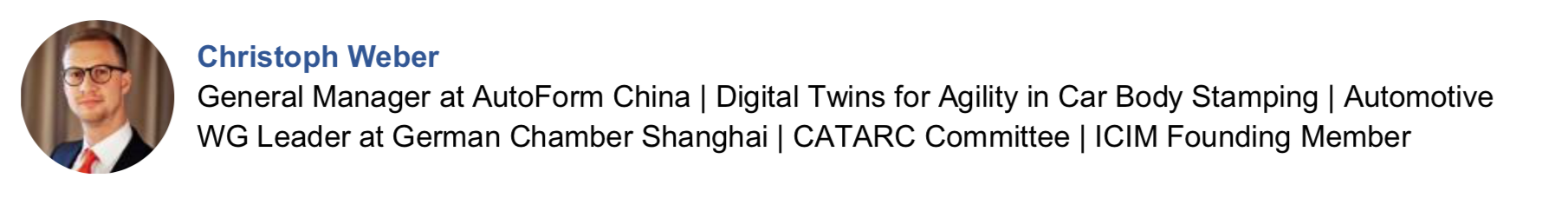

Automotive OEMs need to invest in emerging technologies - new power trains, automated driving, connectivity - while trimming costs to adjust for the new market normal. Nissan announced to cut 20% costs by 2023 in its latest revival plan. Another Japanese OEM aims to reduce even 24% costs in the same time frame, among others through digitalization and simulation technology.

The point is: You can squeeze some five to ten percent costs out of your operation and suppliers, that's possible. But if you want to save 20-30%, you need to fundamentally transform the way you operate.

This economic pressure may enable carmakers to overcome organizational friction to capture the untapped potential of digital transformation. This article explores the opportunity of implementing a physics-driven Digital Twin concept for Agility in car body stamping. First, we identify the organizational, technical and cultural challenges in car body manufacturing projects today. Next, we draw out our vision of Agile project management enabled through a consistent Digital Twin process model on one shared platform. We point out the most vital aspects of this concept and share several examples of what leading automotive companies do today. A return- on-investment calculation for a representative carmaker in China reveals the tangible cost savings. Last, an implementation project schedule outlines how to approach this topic as an automotive OEM.

1) The Challenge: Project Management today

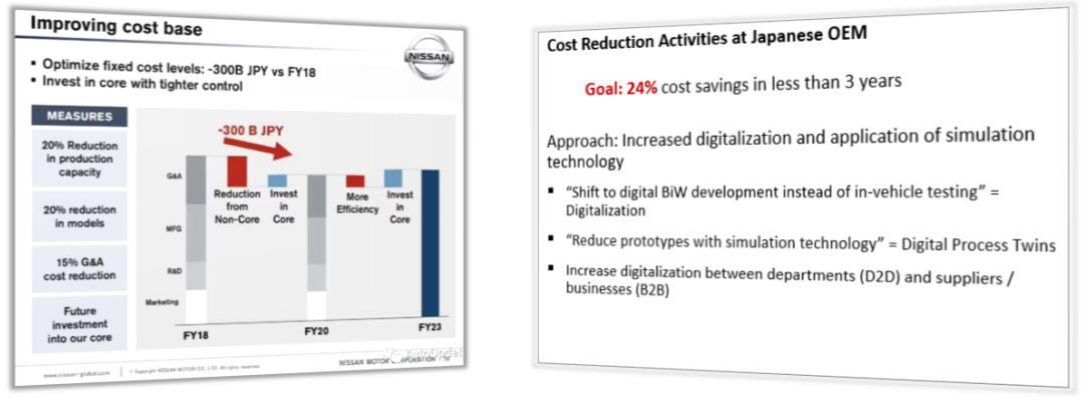

Multiple departments and suppliers need to work together when designing and manufacturing a new car body. However, each department has to achieve its own set of milestones and targets in a waterfall organization. Each department may use different software tools or rely on historic references and individual experience to complete their design and manufacturing concepts. Each of these tools is based on a different understanding andunderlying manufacturing process model.

As a result of this organizational and technical disconnect, engineers focus on their subset of targets and maynot fully consider other departments’ constraints and goals. A significant part of work progress is wasted, sinceinformation and data are not fully transferred from one department to another. Automated feedback loops are impossible. The below graph presents common process models per department and consequences of this disconnect in the form of waste and unreliability.

The design of a car body and its parts already defines 60-70% of its costs, no matter how hard engineering and manufacturing tries to squeeze later on. Still, manufacturing feasibility in design departments mostly relies on rule-of-thumb based on overly simplified manufacturing process models. Deeper manufacturing feasibility analysis commonly only happens in a separate department after the first design drafts are already completed. This work is called "Simultaneous Engineering" even though it actually does not happen simultaneously, but typically by handing part packages back and forth on a monthly interval. Since both departments use different process models for feasibility, little understanding and experience can be exchanged and build-up in either direction. This results in many loops between both departments and ultimately in more expensive and heavy product designs than necessary.

Most carmaker's engineering departments conduct comprehensive simulations for virtual predictions and optimizations of stamping processes in the press shop and welding processes in the body shop. However, little to no engineering data arrives at the physical shop floors and vice-versa there is no systematic feedback data flow from shop floor to engineering.

Engineering departments may ignore real-life constraints on the shop floor, and technicians on the shop floor may not trust the engineering intent and improvise based on their individual experience. This builds a vicious cycle which increases the disconnect in information, trustand culture over time. Break the silos!

Engineering simulations create huge amount of data and are commonly not passed on to other departments, even though they are highly relevant for other technical, commercial and logistical departments. The Geometric Dimensions & Tolerances (GD&T) team commonly does not access stamping and welding simulations, and instead relies on historic project references. This results in over-engineering by defining tight tolerances, not because it is technically necessary, but because this department cannot connect existing data to understand how the subsequent manufacturing processes are linked. Cost Engineering and Purchasing departments rather rely on historic references in Excel for cost control and supplier negotiations, instead of leveraging the internal knowledge about the underlying manufacturing process. This gives away saving potential of designs and margins to suppliers.

The Project Management may receive contradicting information on the same subject, since different departments base their analysis on different process models. Frequent delays and unreliability are the result. Learning from one project for future ones is hindered.

2) The Solution: Digital Twins for Agility in Car Body Stamping

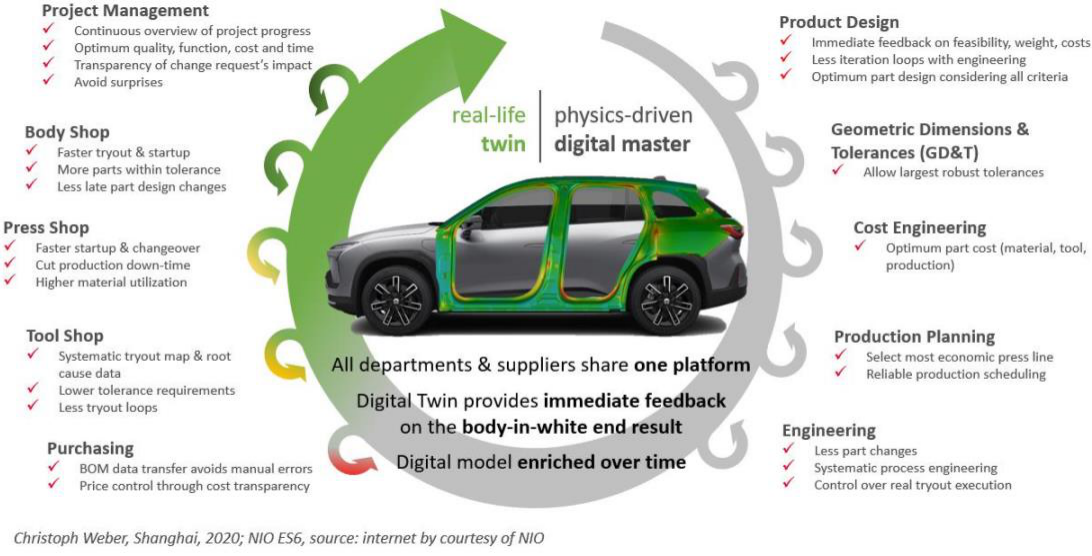

The solution is to share one process model on one platform with all departments and suppliers. The Digital Twin process model connects the virtual and physical worlds and consists of two entities:

1. TheDigital Masteris created first in the virtual world during the design and engineering phase and represents the engineering intent or "as engineered" model.

2. TheReal-life Twinis the physical execution of its Digital Master on the shop floor and provides "as manufactured" data in order to close the feedback loop and enable continuous improvement.

Aphysics-driven Digital Twinis able to predict behavior already in the virtual phase and to self-correct deviations in the physical production phase. This enables Agility in car body stamping through immediatefeedback loops and focus on the body-in-white end result.

What is Agility in car body stamping? (1) Immediate feedback loops by the Digital Twin and (2) everyone focuses on the body-in-white end result to optimize quality, function, weight, cost and time.

Traditional project management followed a waterflow process with several project phases and milestones, which are completed one by one from left to right. In contrast, in Agile projects everyone "sits at one table" or in this case is connected to one platform, and the product and manufacturing concept is matured in multiple iteration cycles over the course of the project. Below graph presents an Agile project cycle from product design until production, based on the Digital Twin concept in car body stamping. On the right-hand side, the Digital Master is refined during the design and engineering phase. For any change in the design or manufacturing concept, the Digital Twin provides immediate feedback to everyone connected to the platform about the impact on the body- in-white end result and relevant data for each department. This allows all departments to align their targets to optimize the body-in-white for quality, function, weight, cost and complexity for a realistic time line.

The left-hand side represents the Real-Life Twin, which is the exact replication of its Digital Master in the physical world. All relevant data are provided to the fulfilling departments such as Purchasing and Production, in order to enable them to execute an exact Real-Life Twin of the engineering intent. Actual manufacturing data and other achieved data are feed into the system. The physics-driven model calculates deviations between the Digital Master and actual data and provides guidance for the shop floor on how to reach congruence. In this way, the feedback loop is closed to synchronize the Digital Master and its Real-Life Twin and to enrich the process model over time for continuous improvement.

As a result, designs are optimized for manufacturing earlier for the final body-in-white to reduce costs, weight and time. The Geometric Dimensions & Tolerances (GD&T) department can leverage virtual stamping and welding process data in order to define tolerances as large as possible while ensuring to meet all functional and quality targets of the final body-in-white. The Production Planning can allocate the most economic press lines to projects early, based on virtual manufacturing concepts' press line tonnage and dimension requirements. The Engineering team can validate and enrich their process models based on actual shop floor data, reaching a new level of accuracy.

The Digital Twin concept leverages data and knowledge of the entire value chain on the shop floor.

The tool tryout can follow a tryout map to reach a robust production process in the most systematic way. The body shop may receive good parts earlier in the pilot phase and this more solid base allows faster ramp-up. This cuts several physical tryout loops in the tool, press and body shops.

The Project Management is automatically updated about the project progress and any design and manufacturing concept update. Coordination between departments is facilitated and information become more reliable, since everyone bases their work on one platform with a consistent process model. Project cycles and changeexecutions become faster and more agile.

3) The Process: From Digital Master to Real-life Twin and back again...

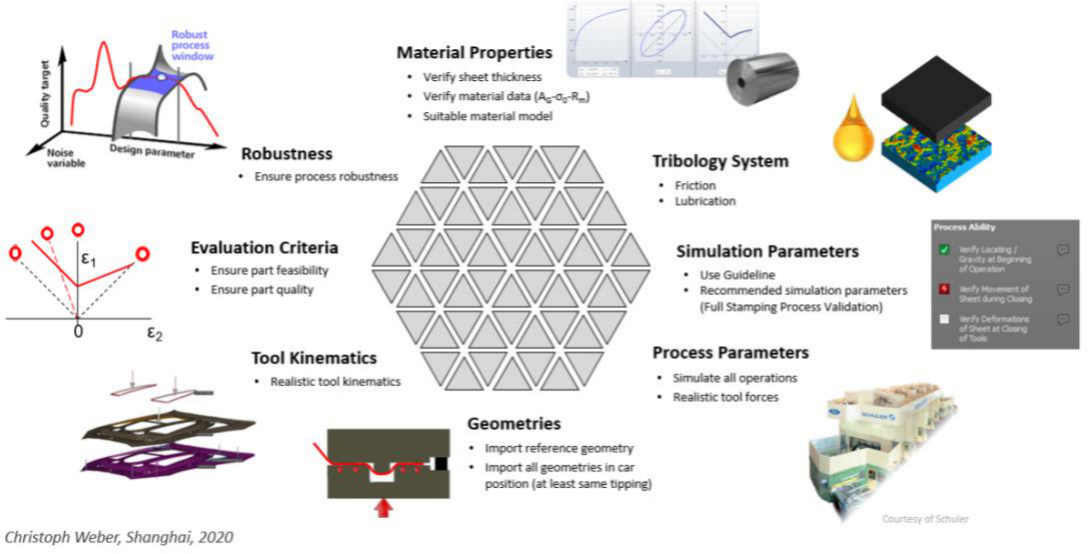

First, engineers build and refine a Digital Master of the manufacturing process in the design and engineering phase. The graph below shows the AutoForm Accuracy Footprint, which covers all critical aspects to accurately represent and predict a stamping process: From material properties to a robustness analysis accounting for noise variables. A meaningful process model forms the base to virtually optimize and validate design and manufacturing concepts. The accuracy increases as the Digital Master process model is enriched over the course of each project and as the overall model and software is continuously improved over time.

Second, all Digital Master’s "as engineered" data are provided to the shop floor in a digestible format, e.g. on acomputer tablet. AutoForm's "TryoutAssistant" software on a computer tablet provides simulation data in the form of an interactive tryout map and advises on the dominant influence factor of any process issues. The Real- life Twin is manufactured and actual measuring data are returned to the platform "as manufactured" in order to close the feedback loop. The physics-driven model calculates deviations and provides guidance to the shop floor on how to reach congruence and ultimately a robust production in the most systematic fashion.

A close and trustful cooperation between engineering and shop floor teams is vital for success. The engineering teams must understand technical constraints in order to design a meaningful manufacturing processes. Theshop floor technicians need to execute the engineering intent with high diligence and feedback any deviations to the system. Improvising off the record would undermine the process and cannot be tolerated.

Not least of all, a cultural gap between the academic-minded engineering department and the hands-on shop floor team must be overcome.

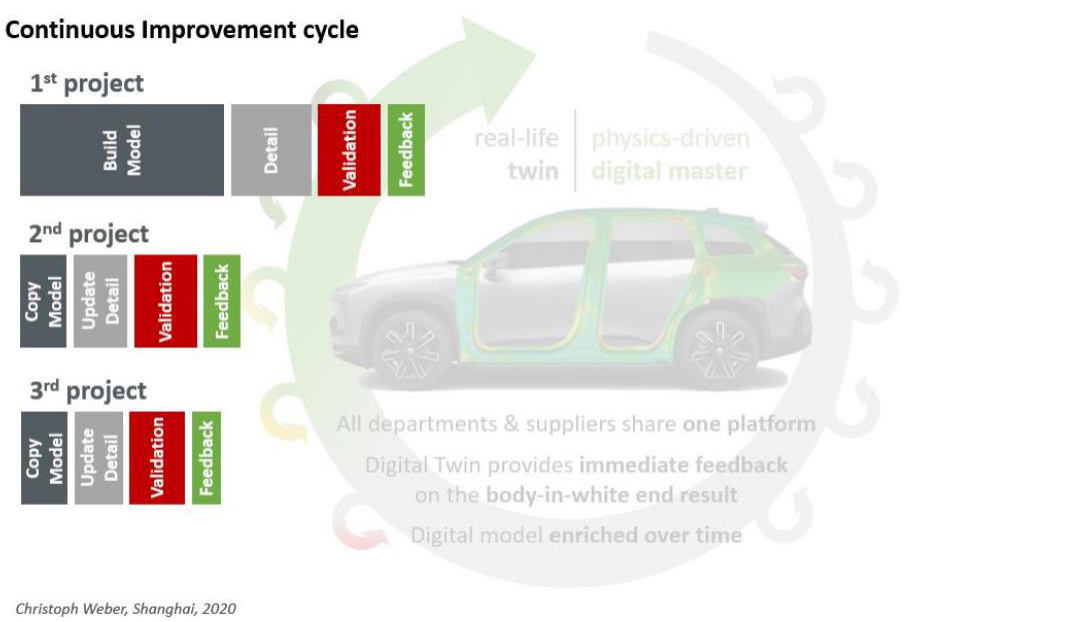

Companies need to invest effort to build the Digital Master process model for the first project. In the following projects however, one can copy the process models from past projects as a starting base. Then, it is mainly about updating details adjustments. Furthermore, feedback from all parties enriches and improves the process model and increases the Digital Twin's effectiveness over time.

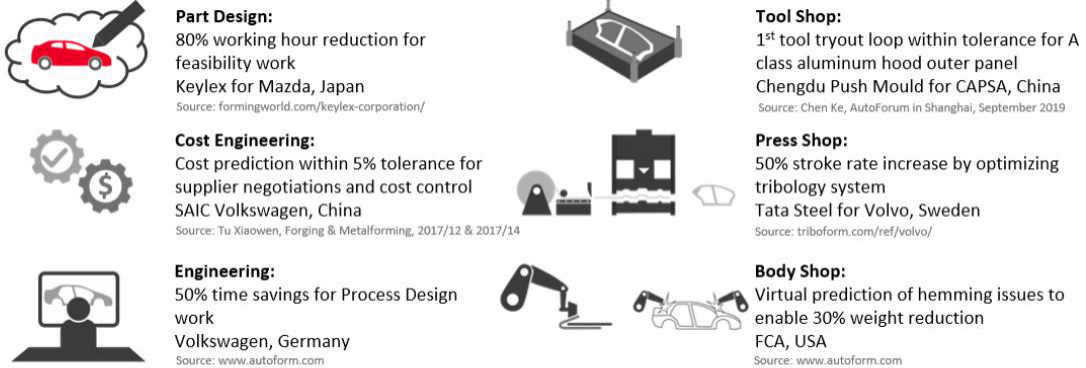

Today, most carmakers are on a digital transformation journey. So far, nobody has reached a full implementation of the Digital Twin concept over the entire value chain of car body stamping yet. Our customers achieved the following results after implementing AutoForm software. Please feel free to reach out for further details, case studies and business cases.

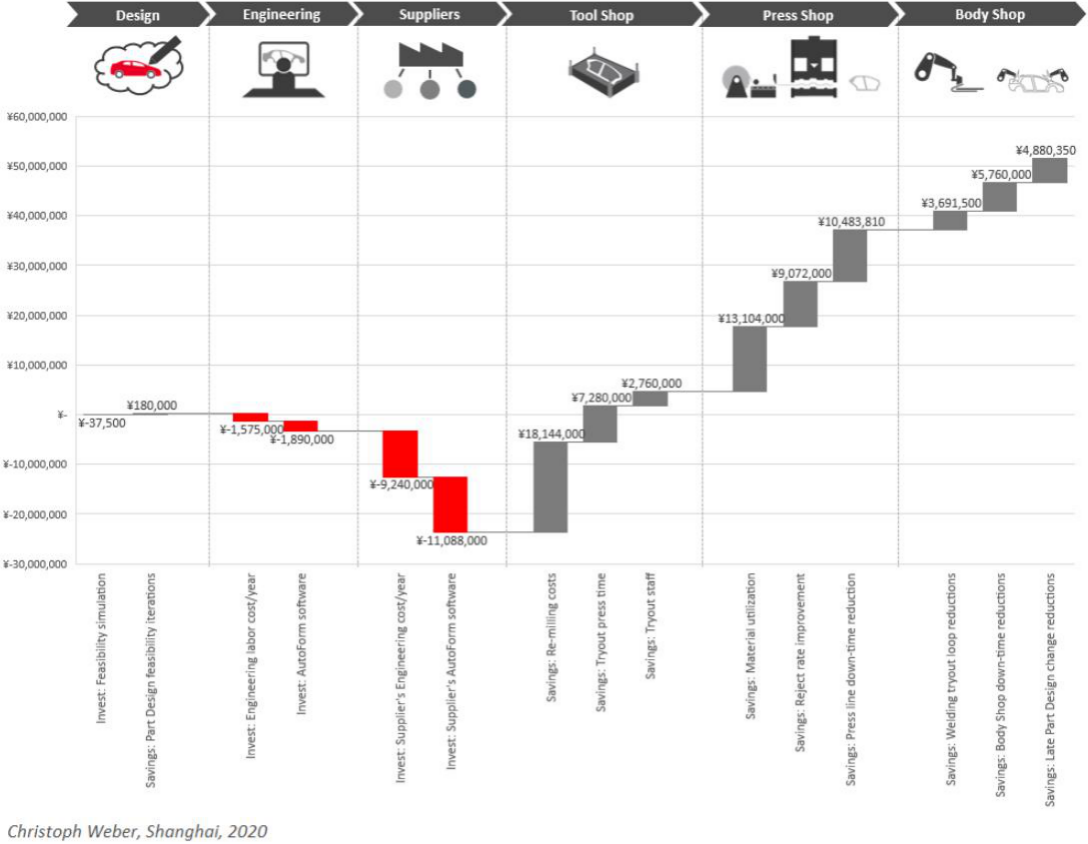

How does an implementation of the physics-driven Digital Twin for Agility over the entire value chain incar body stamping contribute to the targeted cost efficiency gains?For this, we have interviewed countless automotive OEMs and suppliers in China about their cost and performance data in order to draft a representative return-on-investment (ROI) template for the industry.

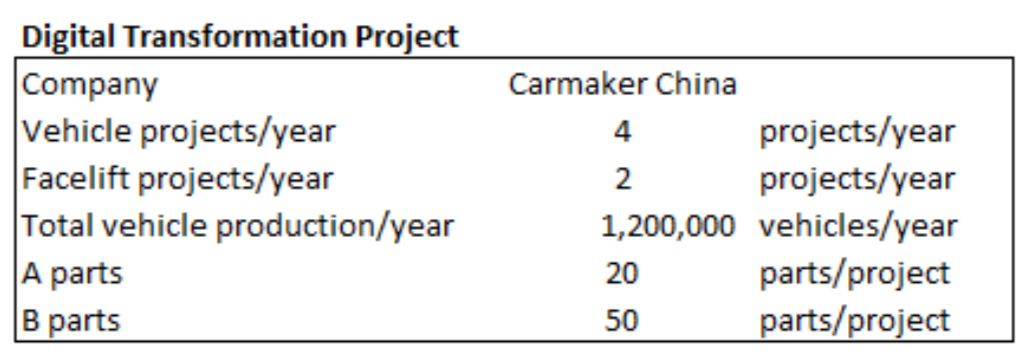

In this article, I would like to show a business case for a typical anonymized carmaker in China. This carmaker produces 1.2 Mio cars and develops four new vehicle projects and additional two face-lift projects per year. The calculation considers 20 common A parts (e.g. body side panel, door panels, hood panels, fenders, ...) and 50common B parts (dash panel, major structure parts, ...) of a car body. C parts are ignored, since costs are low and these are typically manufactured by third or lower tier suppliers, which is out of practical reach for OEMs.

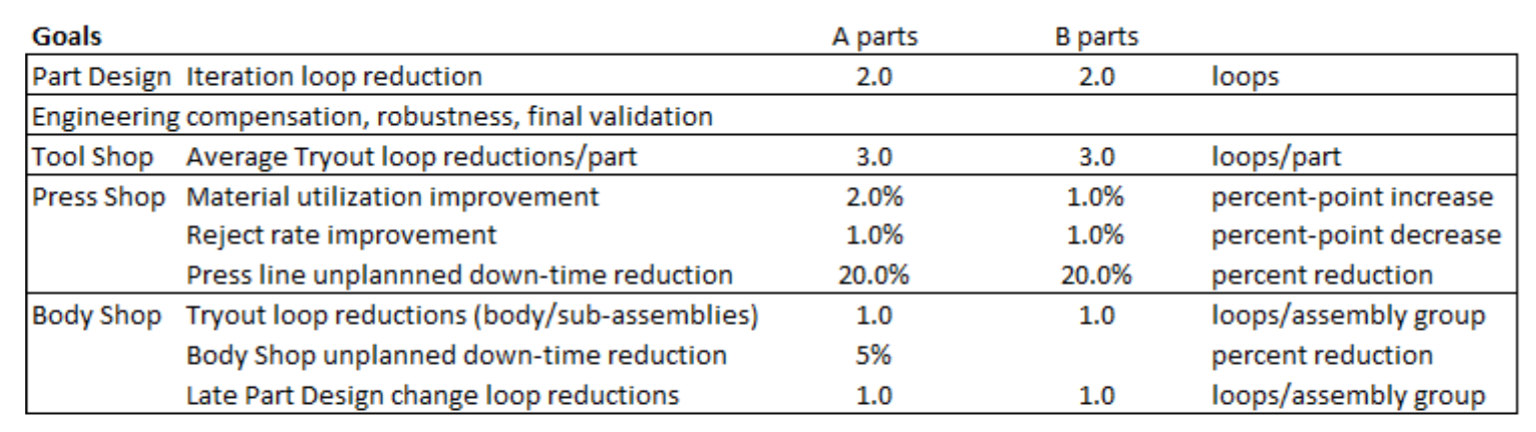

Then, we defined improvement goals for each major field from Part Design to Production as below. Based on AutoForm's past consulting and implementation projects worldwide and in China, these goals are realistic to achieve for most carmakers in China within a 1-2 year implementation project. The customer cases mentioned above show that even far greater improvements are possible, however this business case should stay on the conservative side.

This results in the following business case for this anonymized carmaker in China: An investment of circa 24 Mio CNY/year is required in particular in the early phase in Part Design, Engineering and in supplier's Engineering.We can expect a return of over 75 Mio CNY/year in particular on the physical shop floor. This results in an ROIof over 300% per year for the first 1-2 years. The ROI shall increase further in following years, as the continuous improvement cycles further matures the process model and the enterprises processes and experience.

This underlines that the physics-driven Digital Twin for Agility in car body stamping can contribute significantly to the targeted cost savings in the automotive industry in China.

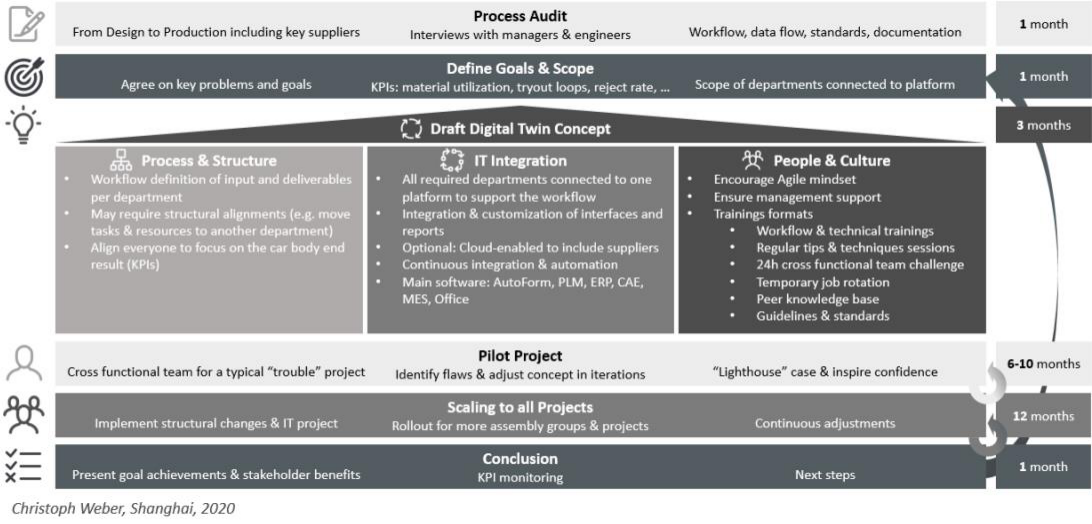

4) The Implementation Plan

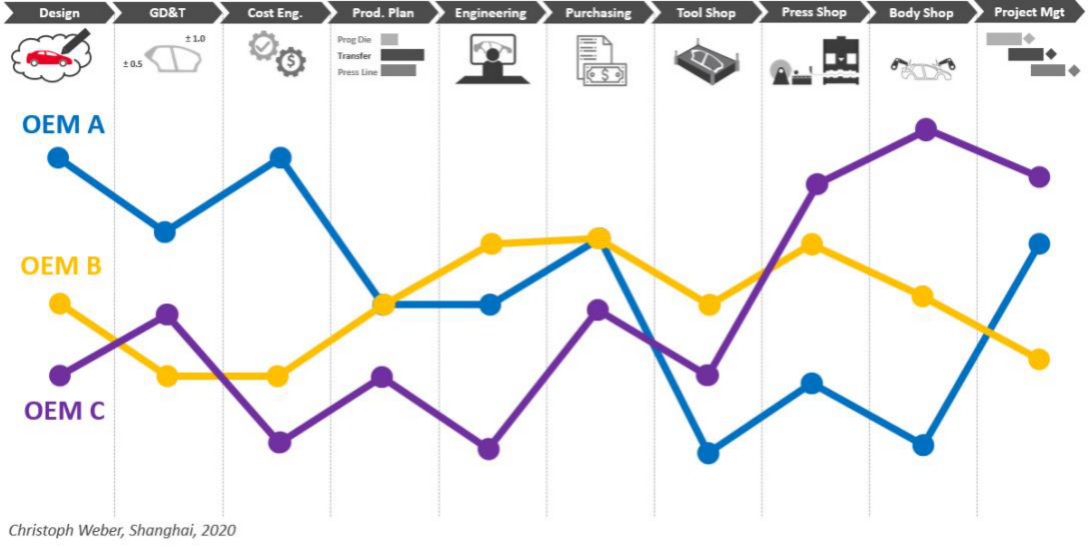

The first step of implementation is to conduct an audit of the company about the process maturity and digitization over the entire value chain from design to production. The core of the audit are interviews with both managers and engineers including suppliers about the workflow, data flow and documentation and a review of standards and guidelines. In particular following the whole workflow of one concrete "trouble" part helps to identify potentials. In our experience, no OEM performs perfectly in all disciplines, but rather reveals strengths and weaknesses in single topics. Below graph shows a comparison of anonymized OEMs. The benchmark reference is mainly based on European and American OEMs.

Based on the audit findings, the management shall agree on what are the most pressing challenges and what goals shall be achieved by the implementation project within a 1-2 year time frame. Goals shall be defined and agreed upon as specific as possible e.g. through KPIs. Furthermore, management must approve the scope of departments which shall be connected to the Digital Twin platform.

The core project team drafts a Digital Twin concept with workflow to define input and deliverables per department. It may even be required to align structures by merging teams or allocating tasks and resources from one department to another. Next, the IT department drafts an architecture to connect all required parties to one Digital Twin platform, commonly based on existing PLM and ERP systems, in order to support the workflow. This transformation of processes and IT technology must be supported by a transformation of people and company culture. More specifically, the subcultures of different departments (and perhaps even suppliers) may require harmonization. This can be achieved through training and workshops, e.g. an interdisciplinary 24h team challenge to optimize an assembly group. Furthermore, it is vital that the management is kept involved and supports the transit ion.

This transformation of processes and IT technology must be supported by a transformation of people and company subcultures.

The implementation should be conducted in an iterative process. A pilot project should prove the drafted Digital Twin concept on a small scale, before implementing the structural changes and IT integration. A cross functionalpilot team from all required departments shall be formed and test the drafted workflow for one typical "trouble" project. This may reveal flaws in the concept which can be adjusted in iterations. As a result, this pilot delivers a verified concept and the first "lighthouse" case to inspire confidence. may reveal flaws in the concept which can be adjusted in iterations. of the drafted process and brings up a first "lighthouse" case to inspire confidence. One or several such projects may be required to establish a feasible process blueprint.

After that, the drafted structural alignments and IT integration can be implemented, in order to scale the Digital Twin implementation gradually to all projects. This roll-out may be handled in phases e.g. per assembly group or per vehicle project. This allows intervention and continuous adjustments whenever required during the implementation project.

The goals and KPIs must be monitored throughout the implementation project and reported to the management. In particular after the pilot project and after the first scaled implementation, the achievements shall be reviewed and next steps defined or adjusted. After an implementation project's completion, it may be natural to initiate a second phase of implementation project in order to capture further potential.

Conclusion

Project management for car body design and manufacturing follows a traditional waterflow organization, where each department works in separate silos. The organizational and IT technological disconnect between departments results in waste in the form of optimization for sub-goals, over-engineering, missing optimization opportunities, time waste and unreliability. The solution is to connect the entire value chain to one platform sharing one consistent physics-driven Digital Twin process model. This enables Agility by providing immediate feedback loops and aligning all departments to optimize the body-in-white end result in terms of quality, function, costs and time.

The implementation of a physics-driven Digital Twin concept for Agility in car body stamping requires process and structural alignments, IT technology integration and harmonizing people and sub cultures of different departments for cross functional collaboration. This is recognized as a classic organizational change process which needs to overcome friction. Today's economic environment provides the required pressure on automotive OEMs to overcome friction to capture the targeted gains in agility and efficiency. A typical carmaker in China cansignificantly increase it competitiveness through the implementation of this Digital Twin concept in car body stamping with an ROI of several hundred percent per year.