MPDV: Towards New Generation

——Interview with MPDV CEO Ms. Nathalie Kletti

Amid the global wave of digital transformation in manufacturing, MPDV Mikrolab GmbH, a leading MES solution provider with 47 years of history and international influence, has always been at the forefront of technological innovation. Recently, Dr. Pei Huang, Editor-In-Chief of e-works, interviewed Ms. Nathalie Kletti, CEO of MPDV, to gain a deeper understanding of MPDV's development history, product advantages, market strategy, and insights into the future of intelligent manufacturing. Mr. Mingfeng Li, General Manager of MPDV China, also participated in the interview.

In Germany, about 75% of the small and medium-sized enterprises (SMEs) are family-owned. Although their revenue may only be several million to a few billion Euros, many of these family-owned businesses are hidden-champions in their industries, and MPDV is one of them. In 2020, according to the company’s succession plan, Ms. Nathalie Kletti was appointed as CEO, while Dr. Jürgen Kletti continued to serve as MPDV’s Executive Chairman.

Ms. Kletti said that takeover the company was a long process. "It's not like you begin on Friday, and it’s done on Monday. It needs time. And I have been prepared for it for 10 to 15 years." She recalled, "When I was a kid, the company was my playground, and now it's my working space. My blood is red, blue and yellow, the corporate identity colors of MPDV."

Ms. Kletti has been working at MPDV for 14 years through various departments such as sales, marketing, consulting, and implementation services, to understand the internal processes and operations of the company. She also worked as an international trainee in Chicago and Singapore, and during her work in Singapore, she visited Shanghai as a consultant to support a customer in China.

The deep emotional bond has made Ms. Kletti full of passion and responsibility for MPDV. Now, Ms. Kletti has fully taken over the company and is ready for its future development. At the same time, although Dr. Jurgen Kletti is no longer working full-time, he still comes in the office three times a week as the mentor and coach to Ms. Kletti. This kind of handover provides solid support for the development of the company.

"I appreciate that he's still here. It's an honor working together with him, and I enjoy that." Ms. Kletti said, "I've been running this company for almost four years and I've done my best. I have great colleagues around the world working at MPDV and together we bring the latest software technology to the world."

Currently, MPDV has around 520 employees worldwide, with wholly owned subsidiaries in Europe, Asia and North America, and about 100 colleagues working outside Germany. Ms. Kletti said that in addition to Switzerland, Singapore, Shanghai, Kuala Lumpur and Chicago, MPDV has opened new offices in Australia and Bangalore, India. No matter wherever the customer is located, MPDV can provide localized support and services. At the MPDV headquarters, the fourth office building is under construction and is going to be finished by the middle of 2025.

"We are moving towards the new generation. As a very creative person, I believe that the image of MPDV on the market will be more colorful. We continue to improve the way we communicate with customers. We are open to our partners, potential and existing customers. We hope to be more successful on markets with our products." Kletti said, "As a family-owned business, MPDV is a stable and long-term partner for our customers. We are committed to constantly incorporating cutting-edge technologies into our products and solutions and are prepared for the future."

Today, with the new slogan of “we create Smart Factories", MPDV's portfolio has expanded from a single HYDRA MES to the MIP platform as well as FEDRA APS system, covering diversified smart factory solutions for both discrete and process industries.

MPDV product portfolio

Ms. Kletti pointed out that today's manufacturing enterprises need flexible software products more than ever to be more competitive. The key challenge is to find the suitable applications, integrating with equipment and IT systems, and connecting via data sharing. When suppliers provide single solutions in the form of manufacturing apps (mApps) and combine them freely, MES systems can be more effective, but it requires a central integration platform.

As early as 2018, MPDV’s pioneering launch of the Manufacturing Integration Platform (MIP) has brought manufacturers the greatest flexibility in choosing the solutions and also provided them with a future-oriented IT architecture. Based on the MIP platform, all mApps from different manufacturers can interact on a common data basis, which means there is no interface dilemma in digital production, but the same digital twin. At the same time, on this open platform, mApps from different suppliers can be combined freely, which creates an ecosystem where all the manufacturers, developers, system integrators, and equipment manufacturers can be benefited from. And enterprises can also combine different production applications from different suppliers according to their own needs. Ms. Kletti explained, "The MIP platform is similar to the operating system on a smartphone, providing a reliable and open basis for HYDRA and other applications to running on."

Based on the MIP platform, MPDV launched the next-generation MES solution HYDRA X. It is composed of many individual manufacturing applications (mApps) and is far more than a traditional MES. For example, it has many functions that support production processes, such as internal logistics of complex assembly production and employee management. With HYDRA X, enterprises can always have a grasp of all resources and plan production processes as efficiently as possible, achieving continuous monitoring, control, and optimization of production, and it can easily be expanded.

FEDRA APS is another major product, an innovative production planning software combining AI. It enables users whether with simple processes or complex production orders realize rapid and flexible scheduling. For example, in complex scenarios, FEDRA can apply AI reinforcement learning technology to optimally allocate available resources to numerous processes, facilitating production planning of multi-resources cross different sites. It also helps multinationals manage their global productions and realize quick response.

After acquiring FELTEN, MPDV integrated FELTEN into its portfolio. This broke the software limitations between the process and the discrete, providing the MIP-based standard MES also for process industries.

When talking about the difference, Ms. Kletti emphasized that compared with other MES suppliers, MPDV is a standard software company. They don’t focus on specific vertical industries but dedicated to providing general technologies applicable to multiple industries. "There are many small MES suppliers in the market who usually customize systems for each customer, so they don't have standards. I think this is the biggest difference between MPDV and them," Ms. Kletti proudly pointed out. "We are a standard software company. 40% of all our installations worldwide are standard installations, which means nothing changed in the system, just out- of-the box. So this is a really high ratio. And among the rest of 60% of non-standard installations, a large part only involves minor changes, such as changing a button in the system from green to yellow. I think this is one of our strengths we have that we are having a high standard. But nevertheless, if the customer has a specific request, we can work on that. For necessary personalized needs, we also provide standard development tools to achieve customized functions."

MPDV’s innovations

Staying close to customer needs and insisting on innovation are also the core strategies of MPDV. "We research again and again. What can we offer? What can we do?" said Ms. Kletti. "Our HYDRA user group is a user group of our product users. It's turning 20 this year. For the last 20 years, we have a really intensive dialogue with our customers, which was the big chance for us to develop our products further ahead."

Facing the booming AI technology, MPDV has also become involved in this field. In 2019, it jointly established a joint venture with the AI specialist Vernaio (formerly PerfectPattern), aiming to combine AI technology and applications with the needs of smart factories. "Just as HYDRA is driven by the needs from the market, we offer our AI components in the way the market needs them, such as AI scheduling, AI capacity utilization analysis, and AI quality prediction," said Ms. Kletti. "Currently, the mass of the companies is not ready to set on AI functionalities. But we are ready for that.” Utilizing AI to fully explore the value of data and create an AI MES will also become an important driving force for innovation in MPDV Group.

Ms. Kletti pointed out, "Some companies are dreaming of achieving unmanned operations in their factories. Some people would say this is a smart factory. But I believe that we still need humans in the manufacturing, and this is never going to be fully automated."

So what is a real smart factory? For MPDV, in a smart factory, production equipment and logistics systems can achieve self-control. Based on an intelligent network, devices and systems can communicate with each other, exchange the manufacturing information, and automatically respond to changes in the production environment. To achieve this, a digital system capable of processing collected data in real time is needed, to make the production transparent, avoid bottlenecks, and optimize the utilization of manufacturing resources. Secondly, humans play a core role in smart factories. Their task is to optimize and control the process. And with the MES system, people can identify the need for action and make targeted decisions. Moreover, AI technology can be used to analyze big data and identify patterns. Digital systems evaluate the manufacturing process based on the perception and predict events or results. These predictions will help people take actions responsively.

Smart Factory Elements

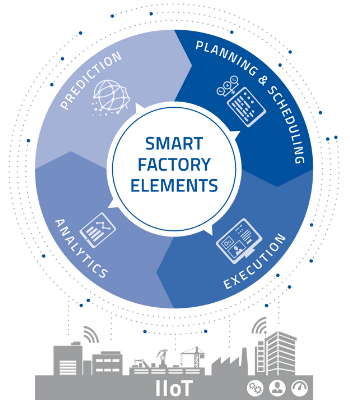

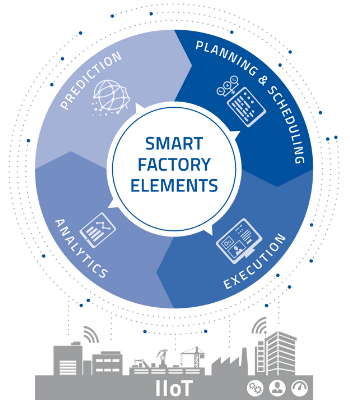

Based on years of market experience, MPDV has proposed the concept of Smart Factory Elements (the five core elements of a smart factory): planning and scheduling, execution, analytics, prediction, and Industrial Internet of Things (IIoT). These elements of a smart factory together form a control loop. In this loop, production is firstly planned based on specifications from different data sources (Planning and Scheduling); then the plan is implemented and executed (Execution); during the order execution process, data is collected and analyzed (Analytics); predictions are made according to data analysis (Prediction); and the results of analysis and prediction, as well as other new factors, are subsequently incorporated into the formulation of the next production plan. The Industrial Internet of Things supports this loop by collecting and processing data.

MPDV’s Smart Factory Model

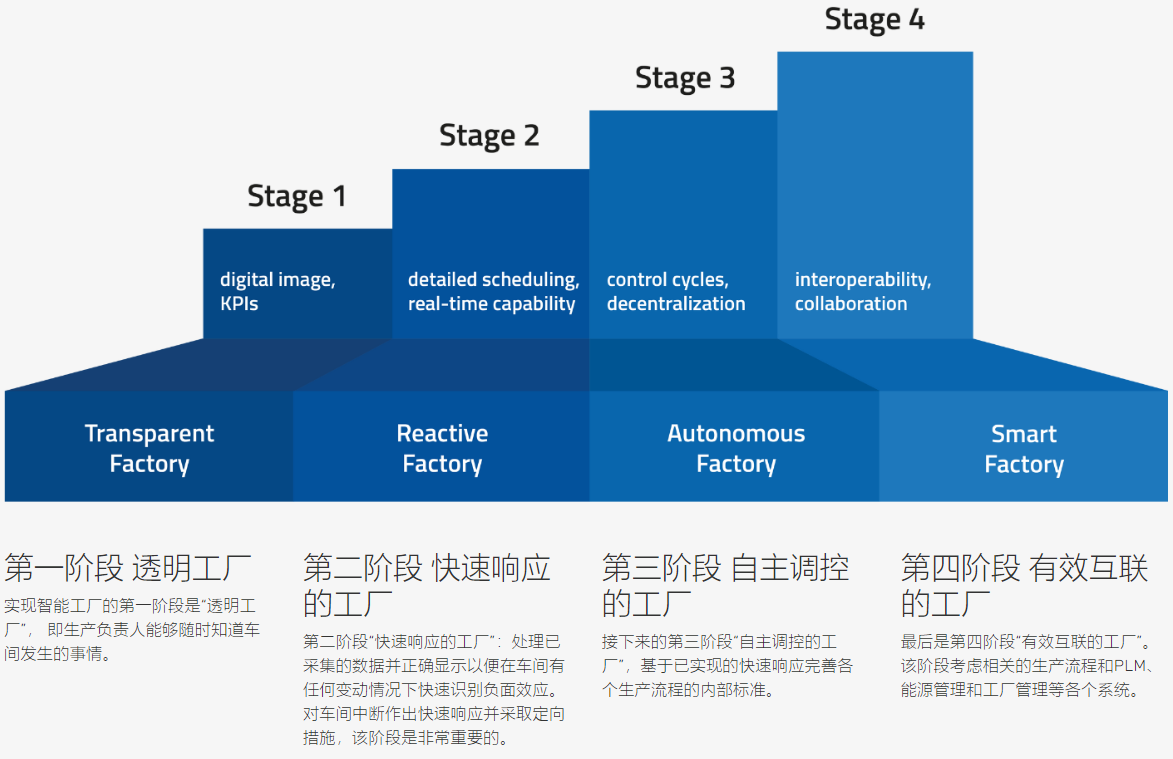

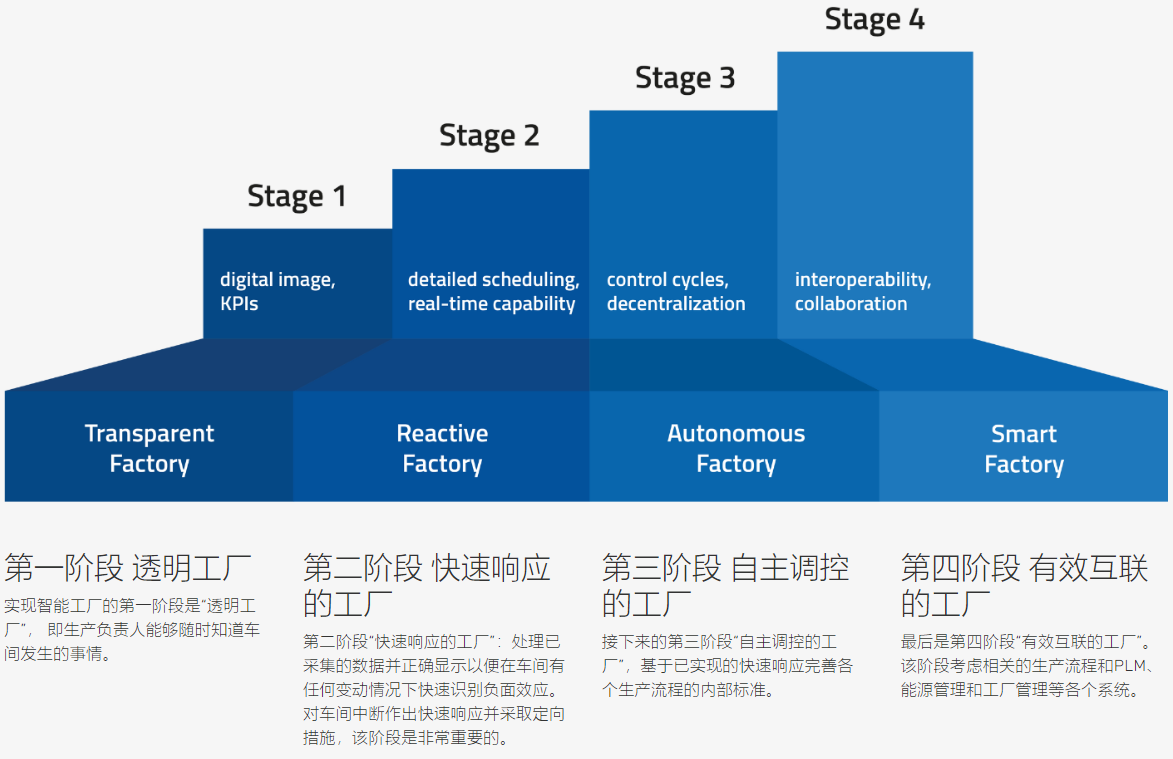

For enterprises on their way to smart factories, MPDV has developed a four-stage model.

The first stage is the "Transparent Factory". At this stage, production managers need to know what is happening in the workshop at any time.

The second stage is to build a "Reactive Factory". At this stage, the enterprise needs to process the collected data through the MES system and display it correctly, so as to quickly identify problems in case of any changes in the workshop and respond quickly to abnormal situations in the workshop and take corresponding measures.

The third stage is to achieve an "Autonomous Factory". At this stage, closed-loop control of production needs to be realized, and based on the quick response, internal standards for each production process need to be improved.

The fourth stage is the "Smart Factory". At this stage, all processes related to production will become digital and intelligent, and should be integrated and collaborated with various systems such as PLM, energy management, and factory management.

“The first step to build a smart factory means that companies need to build all their processes they have in a digital way. And this is, for a lot of companies, a really big step at the moment because they still have paper documents around and really old machines, so it's going to be a long way.” Ms. Kletti admitted, “so therefore, smart factory somehow is a vision, but you need a vision to get step by step better. And creating smart factories is our mission.”

MPDV proposes the concept of "we create Smart Factories". Here "create" means the work MPDV is doing, and "Smart Factories" represent the vision of reaching an "autonomous factory" in the future. MPDV hopes to play a key role in achieving the true smart factories and help enterprises realize this beautiful vision.

Only by taking the first step can we get closer to the goal of a smart factory.

MPDV CEO Ms. Nathalie Kletti and Dr. Pei Huang

Amid the global wave of digital transformation in manufacturing, MPDV Mikrolab GmbH, a leading MES solution provider with 47 years of history and international influence, has always been at the forefront of technological innovation. Recently, Dr. Pei Huang, Editor-In-Chief of e-works, interviewed Ms. Nathalie Kletti, CEO of MPDV, to gain a deeper understanding of MPDV's development history, product advantages, market strategy, and insights into the future of intelligent manufacturing. Mr. Mingfeng Li, General Manager of MPDV China, also participated in the interview.

New Generation CEO

The story of MPDV began in a small town on the River Neckar in Germany—Mosbach. In 1977, Dr. Jürgen Kletti, the father of Ms. Kletti, founded MPDV here. With a passion for technology and deep understanding of manufacturing, he gradually developed the company from a small office with two engineers into a medium-sized software company today, which has become a global MES solution leader.In Germany, about 75% of the small and medium-sized enterprises (SMEs) are family-owned. Although their revenue may only be several million to a few billion Euros, many of these family-owned businesses are hidden-champions in their industries, and MPDV is one of them. In 2020, according to the company’s succession plan, Ms. Nathalie Kletti was appointed as CEO, while Dr. Jürgen Kletti continued to serve as MPDV’s Executive Chairman.

Ms. Kletti said that takeover the company was a long process. "It's not like you begin on Friday, and it’s done on Monday. It needs time. And I have been prepared for it for 10 to 15 years." She recalled, "When I was a kid, the company was my playground, and now it's my working space. My blood is red, blue and yellow, the corporate identity colors of MPDV."

Ms. Kletti has been working at MPDV for 14 years through various departments such as sales, marketing, consulting, and implementation services, to understand the internal processes and operations of the company. She also worked as an international trainee in Chicago and Singapore, and during her work in Singapore, she visited Shanghai as a consultant to support a customer in China.

The deep emotional bond has made Ms. Kletti full of passion and responsibility for MPDV. Now, Ms. Kletti has fully taken over the company and is ready for its future development. At the same time, although Dr. Jurgen Kletti is no longer working full-time, he still comes in the office three times a week as the mentor and coach to Ms. Kletti. This kind of handover provides solid support for the development of the company.

"I appreciate that he's still here. It's an honor working together with him, and I enjoy that." Ms. Kletti said, "I've been running this company for almost four years and I've done my best. I have great colleagues around the world working at MPDV and together we bring the latest software technology to the world."

Currently, MPDV has around 520 employees worldwide, with wholly owned subsidiaries in Europe, Asia and North America, and about 100 colleagues working outside Germany. Ms. Kletti said that in addition to Switzerland, Singapore, Shanghai, Kuala Lumpur and Chicago, MPDV has opened new offices in Australia and Bangalore, India. No matter wherever the customer is located, MPDV can provide localized support and services. At the MPDV headquarters, the fourth office building is under construction and is going to be finished by the middle of 2025.

"We are moving towards the new generation. As a very creative person, I believe that the image of MPDV on the market will be more colorful. We continue to improve the way we communicate with customers. We are open to our partners, potential and existing customers. We hope to be more successful on markets with our products." Kletti said, "As a family-owned business, MPDV is a stable and long-term partner for our customers. We are committed to constantly incorporating cutting-edge technologies into our products and solutions and are prepared for the future."

New Generation MES

Technological innovation usually means the core competitiveness of a software company. "We are always committed to developing cutting-edge solutions to meet the constantly changing needs of our customers," said Ms. Kletti. From the birth of the first standard production and personnel management system HYDRA, to the launch of the world's first modular MES system HYDRA 7, from the VDI 5600-based HYDRA 8 and the innovative Manufacturing Integration Platform (MIP) to the HYDRA X, as well as the continuous exploration and introduction of emerging technologies such as AI and digital twin, MPDV has always been a visionary leader and innovation driver, providing customers with more intelligent and efficient smart factory solutions.Today, with the new slogan of “we create Smart Factories", MPDV's portfolio has expanded from a single HYDRA MES to the MIP platform as well as FEDRA APS system, covering diversified smart factory solutions for both discrete and process industries.

MPDV product portfolio

Ms. Kletti pointed out that today's manufacturing enterprises need flexible software products more than ever to be more competitive. The key challenge is to find the suitable applications, integrating with equipment and IT systems, and connecting via data sharing. When suppliers provide single solutions in the form of manufacturing apps (mApps) and combine them freely, MES systems can be more effective, but it requires a central integration platform.

As early as 2018, MPDV’s pioneering launch of the Manufacturing Integration Platform (MIP) has brought manufacturers the greatest flexibility in choosing the solutions and also provided them with a future-oriented IT architecture. Based on the MIP platform, all mApps from different manufacturers can interact on a common data basis, which means there is no interface dilemma in digital production, but the same digital twin. At the same time, on this open platform, mApps from different suppliers can be combined freely, which creates an ecosystem where all the manufacturers, developers, system integrators, and equipment manufacturers can be benefited from. And enterprises can also combine different production applications from different suppliers according to their own needs. Ms. Kletti explained, "The MIP platform is similar to the operating system on a smartphone, providing a reliable and open basis for HYDRA and other applications to running on."

Based on the MIP platform, MPDV launched the next-generation MES solution HYDRA X. It is composed of many individual manufacturing applications (mApps) and is far more than a traditional MES. For example, it has many functions that support production processes, such as internal logistics of complex assembly production and employee management. With HYDRA X, enterprises can always have a grasp of all resources and plan production processes as efficiently as possible, achieving continuous monitoring, control, and optimization of production, and it can easily be expanded.

FEDRA APS is another major product, an innovative production planning software combining AI. It enables users whether with simple processes or complex production orders realize rapid and flexible scheduling. For example, in complex scenarios, FEDRA can apply AI reinforcement learning technology to optimally allocate available resources to numerous processes, facilitating production planning of multi-resources cross different sites. It also helps multinationals manage their global productions and realize quick response.

After acquiring FELTEN, MPDV integrated FELTEN into its portfolio. This broke the software limitations between the process and the discrete, providing the MIP-based standard MES also for process industries.

When talking about the difference, Ms. Kletti emphasized that compared with other MES suppliers, MPDV is a standard software company. They don’t focus on specific vertical industries but dedicated to providing general technologies applicable to multiple industries. "There are many small MES suppliers in the market who usually customize systems for each customer, so they don't have standards. I think this is the biggest difference between MPDV and them," Ms. Kletti proudly pointed out. "We are a standard software company. 40% of all our installations worldwide are standard installations, which means nothing changed in the system, just out- of-the box. So this is a really high ratio. And among the rest of 60% of non-standard installations, a large part only involves minor changes, such as changing a button in the system from green to yellow. I think this is one of our strengths we have that we are having a high standard. But nevertheless, if the customer has a specific request, we can work on that. For necessary personalized needs, we also provide standard development tools to achieve customized functions."

MPDV’s innovations

Staying close to customer needs and insisting on innovation are also the core strategies of MPDV. "We research again and again. What can we offer? What can we do?" said Ms. Kletti. "Our HYDRA user group is a user group of our product users. It's turning 20 this year. For the last 20 years, we have a really intensive dialogue with our customers, which was the big chance for us to develop our products further ahead."

Facing the booming AI technology, MPDV has also become involved in this field. In 2019, it jointly established a joint venture with the AI specialist Vernaio (formerly PerfectPattern), aiming to combine AI technology and applications with the needs of smart factories. "Just as HYDRA is driven by the needs from the market, we offer our AI components in the way the market needs them, such as AI scheduling, AI capacity utilization analysis, and AI quality prediction," said Ms. Kletti. "Currently, the mass of the companies is not ready to set on AI functionalities. But we are ready for that.” Utilizing AI to fully explore the value of data and create an AI MES will also become an important driving force for innovation in MPDV Group.

How to Build the New Generation of Smart Factories?

The ultimate goal of manufacturing has always been to achieve competitive production. In the era of Industry 4.0, many enterprises hope to create smart factories. MPDV believes that a smart factory is not just a vision but an enabler of higher productivity and stronger competitiveness.Ms. Kletti pointed out, "Some companies are dreaming of achieving unmanned operations in their factories. Some people would say this is a smart factory. But I believe that we still need humans in the manufacturing, and this is never going to be fully automated."

So what is a real smart factory? For MPDV, in a smart factory, production equipment and logistics systems can achieve self-control. Based on an intelligent network, devices and systems can communicate with each other, exchange the manufacturing information, and automatically respond to changes in the production environment. To achieve this, a digital system capable of processing collected data in real time is needed, to make the production transparent, avoid bottlenecks, and optimize the utilization of manufacturing resources. Secondly, humans play a core role in smart factories. Their task is to optimize and control the process. And with the MES system, people can identify the need for action and make targeted decisions. Moreover, AI technology can be used to analyze big data and identify patterns. Digital systems evaluate the manufacturing process based on the perception and predict events or results. These predictions will help people take actions responsively.

Smart Factory Elements

Based on years of market experience, MPDV has proposed the concept of Smart Factory Elements (the five core elements of a smart factory): planning and scheduling, execution, analytics, prediction, and Industrial Internet of Things (IIoT). These elements of a smart factory together form a control loop. In this loop, production is firstly planned based on specifications from different data sources (Planning and Scheduling); then the plan is implemented and executed (Execution); during the order execution process, data is collected and analyzed (Analytics); predictions are made according to data analysis (Prediction); and the results of analysis and prediction, as well as other new factors, are subsequently incorporated into the formulation of the next production plan. The Industrial Internet of Things supports this loop by collecting and processing data.

MPDV’s Smart Factory Model

For enterprises on their way to smart factories, MPDV has developed a four-stage model.

The first stage is the "Transparent Factory". At this stage, production managers need to know what is happening in the workshop at any time.

The second stage is to build a "Reactive Factory". At this stage, the enterprise needs to process the collected data through the MES system and display it correctly, so as to quickly identify problems in case of any changes in the workshop and respond quickly to abnormal situations in the workshop and take corresponding measures.

The third stage is to achieve an "Autonomous Factory". At this stage, closed-loop control of production needs to be realized, and based on the quick response, internal standards for each production process need to be improved.

The fourth stage is the "Smart Factory". At this stage, all processes related to production will become digital and intelligent, and should be integrated and collaborated with various systems such as PLM, energy management, and factory management.

“The first step to build a smart factory means that companies need to build all their processes they have in a digital way. And this is, for a lot of companies, a really big step at the moment because they still have paper documents around and really old machines, so it's going to be a long way.” Ms. Kletti admitted, “so therefore, smart factory somehow is a vision, but you need a vision to get step by step better. And creating smart factories is our mission.”

MPDV proposes the concept of "we create Smart Factories". Here "create" means the work MPDV is doing, and "Smart Factories" represent the vision of reaching an "autonomous factory" in the future. MPDV hopes to play a key role in achieving the true smart factories and help enterprises realize this beautiful vision.

Only by taking the first step can we get closer to the goal of a smart factory.

Conclusion

The story of MPDV is a story of innovation, growth and the future. From a small German town to the world, from the MES expert to the smart manufacturing solution provider, MPDV has always upheld its passion for technology and its deep understanding of the manufacturing industries. Over the past 13 years since entering the Chinese market, MPDV has successfully won the trust of about 100 customers with its high-quality products and services. Ms. Kletti said, "We are wherever our customers are. China has always been a very important market for us because our customers are here. We believe that with our global practical experience, our solutions will also contribute more and more to China’s manufacturing industries.”

MPDV CEO Ms. Nathalie Kletti and Dr. Pei Huang