Start a Digital Twin Journey from Engineering Simulation

The smart product in the future will be comprised of two parts, one is the physical product itself, and the other is the digital twin of the physical product. And simulation will be an important way to unlock the tremendous value contained within the digital twin.

The concept and model of the digital twin was publicly introduced in 2002 by Dr. Michael Grieves. He proposed that a digital informational construct about a physical system could be created as an entity on its own, which was subsequently called the digital twin. Today as customization and smart connected products and services become more prevalent, the digital twin has become one of the focusesinthe industry. Gartner even listed the digital twin as one of the top ten emerging technologies for three consecutive years.

The digital twinof a physical product and its closed-loop feedback and optimizationenabled by connecting product field data comprehensively improve the full life cycle management of the product. By connecting the data information from the research and developmenttosupply chain, from manufacturingtomarketing and usage, the digital twin can largely enhancethe product experience, reducing cost and increasing benefits.

In the implementationprocess of the digital twin, simulation isan inseparable and indispensable part. It isthe basis for both the virtual and real mapping and the virtual control. The development of CAD/CAE and other enabling technologies, especially the simulation haslaid a solid foundation for the digital twin implementation.

Dr. Peyman Davoudabadi, Director of Ansys Customer Excellence in this interview with e-works, shared his insightful views on digital twin technology and the relationship between the digital twin and simulation engineering. Working at Ansys for more than a decade, Peyman has led the Ansys Digital Twin solutions worldwide and driven the integration of Ansys’ simulation technology with those of strategic partners.

Meet the Simulation-based Digital Twin

As technologies of Model-based Definition (MBD), Product Data Management (PDM), model lightweight, and AR/VR become increasingly mature, the data information of a product model is getting more and more complete. "Simulation-based digital twins"—virtual models that allow for data analysis and system monitoring via simulations, are becoming a hot spot because of its advantages of low data dependence, deep insight into mechanism, and good growth of the model.

Peyman’sunderstandingof the digital twin concept is very similar with the one from Defense Acquisition University—an integrated multiphysics, multiscale, probabilistic simulation of an as-built system enabled by Digital Thread, that uses the best available models, sensor information, and input data to mirror and predict activities/performance over the life of its corresponding physical twin.Hebelieves that a digital twin is a multi-faceted dynamic set of smart digital models of a system or a subsystem along with all its constituents, which accurately represent the design of a product, production process or the performance of a product or production system in operation. The digital twin of a physical product or process can be used to monitor assets real-time, enable predictive maintenance and optimize performance of assets in operation. The digital twin also provides data that can be used to improve the physical product design throughout the product lifecycle. This higher-fidelity visibility of enterprise assets and processes can lead to competitive advantages including new business models, warranty cost savings, operations cost savings, and faster new product introduction times.

In this sense, a full digital twin strategy is not an ‘add-on’ to existing product development and deployment processes. Rather, it involves the infusion of simulation technology throughout the enterprise and product life cycle including conceptual design, engineering, manufacturing, testing, service, support and customer operations. Digital twins are a natural extension to the model-based systems engineering (MBSE) framework as it leverages and reuses models and simulations, connecting them to real-time data streaming from the asset, to ascertain the current configuration and performance of the asset as it is in the field, perform predictive analytics and maintenance, proactively determine prescriptive solutions, and provide insights to improve future product designs.

Engineering simulation has traditionally been used for new product design and virtual testing, eliminating the need to build multiple prototypes prior to product launch. With the emergence of the Industrial Internet of Things (IIoT), simulation models of the product or process is connected to sensors capturing data from the asset in operation. Leveraging the comprehensive multiphysics-based insights, engineers, operators and maintenance teams can determine not only what component and when an asset will fail but also why and how it will fail, and how to operate an asset in the most optimal possible way.

Especially in the era of Internet of Things when smart connected productdesignersare facing increasedchallenges, simulation is becoming more crucial for the digital twin applications.

Peyman explained that multiphysics-based simulation provides a digital prototyping capability that can shorten the development cycletime, accelerate time to market, reduce overall production costs, reduce warranty costs, reduce number of after-release engineering changes that can affect manufacturing, and increase the rate of successful new product introductions. Simulation also provides high-fidelity insights that can assist in understanding potential failures, future product improvements and redesigns. Furthermore, sensor placement and integration are challenging. The sensor designs integrated into smart products need to be efficient and well designed to achieve low power and robustness, and the same benefits of using simulation early on in the design process for smart connected products is applicable to the sensors themselves.

The Architecture of Ansys Digital Twin Technologies

For challenges in deploying digital twins at scale, Peyman divided them into four stages, namely company’s maturity curve in digital transformation, company’s adoption of simulation software in their R&D and product design, integrating into their IoT and PLM systems, and integrating the solution into their ERP, ALM, SCM systems.

“For those different challenges, the Ansys simulation platform delivers the best-in-class simulation technology and we have been the forerunner in 3D multiphysics simulations for the past 50 years. The capabilities span structural, thermal, fluids and electromagnetics disciplines, and their coupled effects on one another,” he said. Based on Ansys’ broadest and deepest suite of simulation technology, engineers can create the digital twin of a products or process and connect with the sensor data from the field to form a closed-loop feedback and optimization, and thus realize the mapping of a physical product in the virtual world.

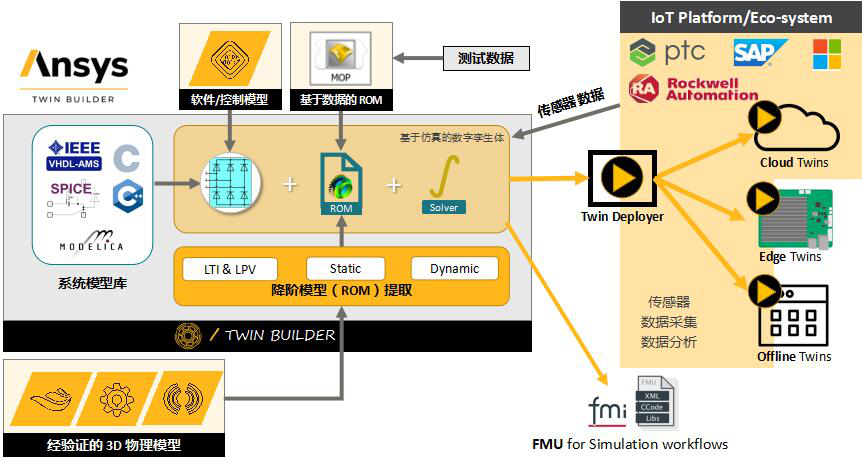

In architecture, Ansys’ digital twin technologies are comprised of five parts: System-level support, control systems, complete technology platform, physics-based simulation, and integrated digital twin eco-system. Engineers can not only replicate the physical characteristics of an asset virtually but also simulate various operation conditions via the digital twin system that covers the full product life cycle from design to operation.

The Architecture of Ansys’ Digital Twin Technologies

The Architecture of Ansys’ Digital Twin Technologies

First of all, the Ansys Twin Builder system-level modeling tool makes it possible to build digital twins that accurately describe complicated interactions between components, subassemblies and subsystems. It also supports the third-party tools and functional mock-up interface standard, which helps combine models from various sources into a comprehensive system description. With Ansys Twin Builder, engineers can connect digital twin models to a variety of industrial internet platforms.

Secondly, Ansys SCADE control system solution enables engineers to connect the digital twin of a product with its physical testing data and simulate different scenarios to supplement the incomplete data analysis through traditional IoT platforms. Besides, using Ansys SCADE software, the system model can be disconnected from the physical asset and operated offline to explore proposed operating scenarios.

Thirdly, the digital twin modeling and deployment requires creating or adopting a flexible and adaptable platform that is open and collaborative to integrate design/simulation/verification with the data being generated. Ansys Minerva can provide engineers with simulation process and decision support and can greatly simplifies the process of connecting multiple digital twins to the IoT.

Fourthly, Ansys provides a full suite of physics-based simulation tools, including structure, fluids, and electromagnetics to enable a digital twin to deliver accurate, insightful and reliable results that can have a real impact on product life cycle, thus reducing time to market, improving output, decreasing downtime and extending longevity.

In addition, to further unlock the value of the digital twin, Ansys has long been working with its partners to promote its digital twin strategy. Ansys simulation platform is already proven to work in tandem with a wide range of popular IoT platforms such as PTC’s ThingWorx, SAP’s Predictive Engineering Insights, Microsoft’s Azure, and Rockwell Automation.

(https://www.ansys.com/zh-cn/about-ansys/partner-ecosystem/software-partners/sap,https://www.ansys.com/about-ansys/news-center/11-04-19-ansys-extends-digital-twins-simulations,https://www.ansys.com/blog/optimize-industrial-automation-systems-digital-twins)

Building a Wide Ecosystem

As Peyman said, “we recognize that no one entity can deliver best-in-class solutions across all aspects of the entire digital twin and digital thread technology spectrum. We believe that it is absolutely essential to partner with others and leverage the best of their digital solutions with ours to cover the entire ecosystem. IoT platforms do what they do well in terms of internet connectivity and communication, sensor data ingestion and collection, security and authentication, and we do what we do best which is engineering simulation.”

That’s why Ansys has focused on the interoperability of its platform. The connectivity to PLM, CAD, IoT, PLC and ERP systems is necessary for true realization of the digital twin across the product life cycle. Over the past few years, Ansys has invested extensively in simulation-based digital twin technology and has created strategic partnerships with industry leaders in this area, such as Rockwell Automation, PTC, Microsoft and SAP.

https://www.businesswire.com/news/home/20191119005919/en/

For example, Ansys and PTC have jointly developed a platform solution enabling digital simulation for IIoT. Taking an operating pump as an example, the digital twin of the pump shows how a digital twin processes sensor data generated from an instrumented asset and leverages simulation to predict failures and diagnose inefficiencies. This enables an organization to take action to immediately correct problems and optimize the asset’s performance. Compared with traditional methods, digital twin-based solutions can diagnose and solve pump operation problems faster and more accurately. Through the cooperation of Ansys and PTC, digital twin-based solutions for pump and valve have been successfully expanded to the field of motor and power transmission.

(https://www.ansys.com/zh-cn/about-ansys/news-center/05-17-17-ptc-ansys-develop-platform-solution)

The deep cooperation with ecosystem partners is bringing Ansys with competitive advantage in the field of digital twin. “Our simulation-based digital twin solutions are built on a foundation of Simulation Process and Data Management (SPDM) and Process Integration and Design Optimization (PIDO), best-in-class high fidelity 3D multiphysics pervasive simulation, embedded software, and systems level simulation and integration. From a strategic perspective, a key differentiator is our platform interoperability allowing customers to leverage their internal and commercial systems and tools with our platform. This enables our customers to build and deploy digital twins at scale,” said Peyman.

To help accelerate the adoption and implementation of physics-based digital twin technologies across multiple industries, Ansys is joining Microsoft, Dell and Lendlease on the steering committee of the Digital Twin Consortium. The extensive cooperation between Ansys and its many partners shows that simulation technology is more than a tool for engineers to design better and reduce physical testing cost. As digital twin adoptions increase, simulation has been extended to a broader field of product health management, remote diagnosis, intelligent maintenance, and shared service.

(https://www.ansys.com/zh-cn/about-ansys/news-center/05-19-20-ansys-microsoft-dell-lendlease-unite-to-expedite-digital-twin-adoption)

Digital Twin Practices

According to Dell Technologies, 78% of business leaders from around the globe believe digital transformation should be more widespread throughout their organization, and digital twins are a large part of a businesses’ digital transformation. 75% of organizations implementing IoT are already using digital twins or plan to within a year.

So far, Ansys has helped many enterprises adopt and implement digital twin technologies. For example, Verbund, Austria’s largest electricity provider, wanted to be able to predict the wear on their turbine under different loading conditions to optimize the turbine output because that any unplanned downtime of the turbine can cost up to $60,000 per hour. By optimizing operations of the turbine with the digital twin, Verbund can save about $100K per turbine per year. Verbund operates more than 120 plants and can deploy up to 120 digital twins.

Another example, a digital twin solution was created for a customer’s CPG manufacturing line by connecting to their factory automation software/hardware with Ansys platform. The digital twin duplicates the asset and predicts performance of the system, accurately enabling design changes and asset performance optimization through virtual sensors and what-if scenarios without any interruption in the physical asset’s performance.

In Europe, Ansys Channel Partner CADFEM demonstrated another digital twin application for Phoenix Contact to determine the behavior and lifetime of safety relays by combining a multiphysics multi-domain simulation model of the whole system connected to the real-time data of an operating relay. Unplanned downtime of a production line due to the failure of a relay can cost tens of thousands of dollars per hour. It also is very hard to predict relay failure as there is no wear sensor. A simulation-based digital twin, however, was created that predicts the wear based on the actual load and sensor data (i.e., temperature and switching frequency), thus lowering unplanned downtime.

(https://www.ansys.com/resource-library/article/fail-safe-digital-twin-aa-v13-i1)

Peyman pointed out that “while the digital twin itself may have been designed using nominal conditions, once deployed, the digital twin typically lives in an inherently uncertain and variable environment. It is important that the digital twin is validated with field data that captures the variability in the environment. Furthermore, each digital twin needs to be calibrated, or tuned, and periodically re-calibrated to its physical twin to track its unique performance in the field. Because our digital twins are simulation based we can perform sensitivity analysis to understand how parameters impact equipment failure modes and build robustness into our digital twin designs. Moreover, using failure data generated from simulations, machine learning can be trained to create and validate models for predictive maintenance.”

As for the future trend of digital twin technologies, Peyman admitted that right now the computational speed and memory space in edge computing is limited, however with advancements, the ability to sense, compute, and predict issues right at the edge will foster real-time insights. Low-latency satellite internet and 5G will increase the adoption of low-power, high bandwidth sensors for IIoT, and this will likely result in more deployments of digital twins in households, industrial applications, and in remote environments. Advances in AI, ML, and deep learning strategies could also drive more hybrid digital twins and increase the adoption rate.

Dr. Peyman Davoudabadi, Director, Ansys Customer Excellence, is responsible for Platform teams and solutions in Simulation Process and Data Management, Materials Information Management, Process Integration and Design Optimization, and Digital Twin across North America. The Platform team is the focal point of Ansys Digital Transformation solutions that help transform customer’s businesses.

He has been with Ansys for over 13 years. Prior to his current role, Peyman led Ansys’s Digital Twin solutions worldwide integrating Ansys’s technologies with those of a strategic partners ecosystem including GE, PTC, SAP, and Rockwell Automation. Peyman earned his PhD in Mechanical engineering from the University of Illinois at Chicago. He also holds an MBA degree from Northwestern University, Kellogg School of Management.

The two other contributors are:Jonathan Kyle (Senior Application Engineer, Digital Twin) and Tyler Bruns (Lead Application Engineer, Digital Twin)