Simulation Technology Empowers Metal Additive Manufacturing

Additive manufacturing is a name to describe the technologies that build 3D objects by adding layer-upon-layer of material, which can be seen as a “from-the-bottom-up-method”. It realizes the integration of structural design, high-performance material preparation and complex component manufacturing, bringing revolutionary changes to the industry at both macro and micro levels.

As additive manufacturing technology makes continuous progress, especially in metal additive manufacturing along with additive manufacturing service, enterprises can effectively manufacture complex metal parts, which leads to a whole new manufacturing mode. And the application of simulation to additive manufacturing can not only ensure the quality of the final product, but also help enterprises simulate the whole additive manufacturing process to minimize the risk of additive manufacturing failure.

In the interview with e-works, Dr. Brent Stucker, Director of Additive Manufacturing at Ansys, mentioned that metal additive manufacturing is becoming a widely used method, changing the way enterprises launch products. The combination of simulation technology and metal additive manufacturing technology helps address the challenges and risks of metal additive manufacturing, so as to build more powerful and lightweight products and parts.

3D-Printed Rocket Engine

Values and Challenges of Metal Additive Manufacturing

In principle, additive manufacturing technology decomposes complex 3D objects into a series of layer addition of materials. It can directly manufacture prototype or direct parts without using molds, which shortens the cycle from design to prototyping, and improves production efficiency and manufacturing flexibility, bringing great value to traditional manufacturing industry. Hence, additive manufacturing technology, especially metal additive manufacturing, has been brought to the forefront.

Through the surveysbyDr. Brent Stucker, metal additive manufacturing technology has made remarkable improvements over the past decade. "There are billions of dollars of R&D going into applications of metal AM today. As these R&D efforts mature, I see a substantial growth opportunity for metal AM in the near future." Commented Dr. Brent Stucker.

Today, metal additive manufacturing is applied more and more extensively in aviation, automotive, medical, scientific research and other fields, with huge market potential. It can be said that metal additive manufacturing is one of the biggest trends in the field of modern manufacturing. More and more enterprises have begun to actively explore the market, including 3D Systems, Desktop Metal, EOS, Renishaw, Stratasys, SLM Solutions and other mainstream 3D printing manufacturers.

Generally, the value of metal additive manufacturing to traditional manufacturing enterprises mainly lies in product design and manufacturing. In the design stage, R&D personnel can make corresponding prototypes with the help of additive manufacturing technology, which can greatly reduce the product R&D cost while shortening the R&D cycle. In the manufacturing stage, additive manufacturing can also eliminate the unnecessary links in the traditional manufacturing process and further improve the utilization rate of materials. As additive manufacturing has the advantage of rapid prototyping, no assembly is required, thus shortening the product supply chain and saving labor.

At the same time, Dr. Stucker holds hhthere are several important challenges in metal additive manufacturing, including: selection of the best orientation for the build, creating optimum supports, avoiding build failure, creating accurate parts, minimizing porosity, achieving the desired properties of the part, optimizing the machine process parameters for greatest productivity and ensuring that the machine is operating as intended while it is building the part.

Other factors that restrict the development of metal additive manufacturing include material availability, dimensional accuracy, additive manufacturing equipment, etc.

First of all, the range of printing materials needs to be expanded because of the high requirements of metal AM materials. The materials should not only be conducive to prototyping, but also have better subsequent process performance, and meet different requirements of strength and stiffness.

Secondly, the dimensional accuracy and quality requirements of the build are high. Large size and high precision are important orientations of additive manufacturing technology. Only when the dimensional accuracy and surface quality reach the level of traditional machining, can they be popularized on a large scale.

Thirdly, manufacturing accuracy and speed need to be balanced. Since additive manufacturing is the process of building objects by layer addition of material, when the layer is thin, the accuracy is higher, but the prototyping takes longer. If the prototyping is shortened, the stair stepping effect is expected to increase.

In addition, the cost of manufacturing and materials is still high. Due to the material limitation for additive manufacturing, along with the specific preparation process, the material price is relatively high, which increased the overall cost.

Advantages of Simulation Technology in Additive Manufacturing

As exciting as AM is, the cost of trial and error is rather high. Therefore, the application of simulation tools in metal AM has a significant impact on the cost control of enterprises. It is an important method to obtain the performance of additive manufacturing products in advance using simulation technology. And by prediction and optimization, the failure rate can be greatly reduced.

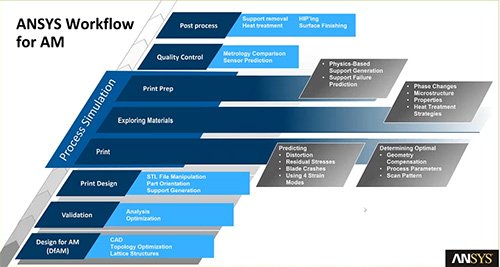

Simulation can be used to analyze the whole process of additive manufacturing from the early design to the end product. Not only can enterprises rely on traditional simulation tools to ensure that the performance of the final products, but also can they simulate production processes with new process simulation solutions.

Dr. Brent Stucker believes that the advantages of simulation technology in metal additive manufacturing are mainly reflected in three aspects: new materials, new designs, and new production workflows.

In the case of new materials, simulation can help users develop process parameters for implementing new materials into AM machines much more quickly, with less experimental trial and error. For new designs, simulation can create new shapes using topological or lattice optimization, and it can also guide the designer by giving feedback on various design ideas the designer has with respect to their manufacturability using AM as well as the effectiveness of their designs in the final product/system. In the case of new production workflows, simulation can help guide designers to eliminate multiple manufacturing and assembly steps by combining various components that previously were designed to do one job in a complex system (such as carry load, transfer heat, provide fluid flow, etc.) into one highly complex component able to handle multiple physics and jobs at a time. Multi-physics simulation is particularly helpful with this last example.

With the help of simulation technology, metal additive manufacturing technology has gained many irreplaceable advantages compared with traditional manufacturing technology: It can be used to manufacture parts and structures that would be difficult or impossible to achieve with traditional manufacturing methods, such as parts with complex internal structure or bionic structure; it can combine the manufacturing and assembling stages into a single process; parts with better performance can be designed and produced with more efficient material utilization; it can be used to manufacture metal replacement parts on demand, without using the whole factory or multiple machines; it can be used to produce new materials with unique properties; worn or damaged parts that have been discontinued can be replaced.

Ansys Empowers Metal Additive Manufacturing

Dr. Brent Stucker said that metal additive manufacturing is of great significance to traditional manufacturing enterprises. It has shown value for everything from prototypes for early design evaluation to tooling for mass production to direct part manufacture to jigs and fixtures for assembly operations, and more. To some extent, metal additive manufacturing technology has the potential to change the competitive pattern of enterprises.

On this basis, Ansys acquired 3DSIM, the leader of metal additive manufacturing simulation technology, in 2017. After acquired 3DSIM, how does Ansys successfully integrate 3DSIM's simulation solution for additive manufacturing with Ansys’ existing technology?

Dr. Brent Stucker made the following remark: The 3DSIM team was integrated into the Ansys Mechanical Business Unit immediately after acquisition. Since that time, Ansys developed a unified Ansys Additive Suite product that includes functionality from leading Ansys solvers, such as MAPDL, and new 3DSIM solvers. This combination gives customers the benefits of using industry-leading Ansys solvers that are highly valued across many industries along with brand new capabilities from 3DSIM. As a result, Ansys now has the greatest breadth of simulation tools for AM available in the marketplace.

Ansys simulation solutions for metal additive manufacturing

In Ansys Additive Prep tool, users are guided through a process of orientation optimization, support generation and build file preparation.

In Ansys Additive Print and Workbench Additive tools, users can predict build failure mechanisms and part distortion during AM as well as during heat treatment and cut-off after the AM process is complete. Workbench Additive, a feature within Ansys Workbench, provides seamless workflow with topological optimization to help designers and analysts ensure better design for additive manufacturing.

With AnsysAdditive Science,Ansys helps the users create optimum process parameters for existing and new materials. By predicting part porosity and microstructure for user-selected process parameter combinations, users can develop high-quality parts that are built as fast as possible, with the correct mechanical properties. And by predicting what thermal sensors in the machine should measure if the process is operating correctly, Ansys can help users determine if their machine is operating as intended.

“Over the last few years Ansys has invested heavily in topological optimization. We have a completely new methodology for utilizing level set topology optimization. As a result, we have leap-frogged our competitors and offer both the traditional SIMP method along with new capabilities only possible via level-set. We also have integrated our topology optimization tools with our Additive tools to give users the ability to put AM-specific constraints on their models.” Dr. Brent Stucker stressed.

Another amazing innovation in topology optimization is the integration of these tools into Ansys Discovery Live environment. Discovery Live is a GPU-driven real-time simulation environment for designers. When a designer changes anything about their design, they can watch fluid flow, carry load, transfer heat, etc. change in real-time.

In the field of materials, there are a number of additional development efforts going on within Ansys to provide material scientists additional predictive capabilities with respect to additive manufacturing. Dr. Brent Stucker said: “We believe this is an area where simulation can provide tremendous value and in each release we hope to increase the value our material science-related customers receive.”

Embrace Additive Manufacturing Technology to Achieve A Win-Win Situation

As for the development trend of metal additive manufacturing, Dr. Brent Stucker is confident that in the next 5 to 10 years, additive manufacturing will become an essential tool for enterprises to compete, and enterprises not adopting this method may fall behind. And thus, Ansys is constantly improving the simulation technology for metal additive manufacturing to help the customers as well as the whole industry achieve a win-win situation.

The potential of metal additive manufacturing is infinite. It can not only promote the cooperation within the enterprise, reduce the design time and cost, but also encourage engineers to create innovative products.

Founded in 2015, Relativity Space has a unique vision: to leverage additive manufacturing technology to 3D-print rockets that can be launched into space. The company designed a rocket engine named Aeon, which includes just 100 parts and is produced in three print runs. The Relativity product development team leveraged Ansys Fluent software to conduct computational fluid dynamics (CFD) simulations of the engine’s injection element, cooling holes and manifold. The company’s engineers also used Ansys Mechanical to assess structural stresses inside the Aeon engine during important events such as liftoff. On top of that, Relativity leveraged Ansys Additive Suite to optimize the 3D printing process, from materials composition to machine settings.

Relativity SpaceAeon: the first 3D-printed rocket engine

With all the benefits, how should the starters formulate their strategies to develop additive manufacturing? Dr. Brent Stucker suggested: “It is daunting for a company to figure out how to make use of AM. To start exploring AM, I recommend companies form a high-level team that is targeted with identifying opportunities and leading the implementation of AM for the company. This team is typically needed for a couple years until AM becomes ingrained in the culture and operations of the various departments that need it. That team should look at applications, technologies, and software tools. I often recommend that team attend the leading users group meeting, the Additive Manufacturing Users Group, and the major trade shows in their region of the world. It can be helpful to bring in an external consulting group to help them get started.

Brent Stucker,Ph.D. is Director of Additive Manufacturing (AM) at Ansys. He is the co-founder and former CEO of 3DSIM, acquired by Ansys in 2017.

Dr. Stucker received his Ph.D. from Texas A&M University, and B.S. from the University of Idaho both in Mechanical Engineering. He has been a leading researcher and industry expert in additive manufacturing for over 25 years. Dr. Stucker has been the recipient of numerous AM awards, including the2016 International Freeform and Additive Manufacturing Excellence Award.He was a professor from 1997-2015, with various appointments at renowned Universities. Dr. Stucker also holds numerous patents and has authored and co-authored over 200 technical publications on AM.