Eplan: Leading the New Wave of Global Electrical Automation Engineering Software

——Interview with Mr. Sebastian Seitz, CEO of Eplan

On electrical engineering and automation design software market, Eplan, with its innovative digital technology and excellent software solutions, has served more than 68,000 customers around the world, and became the global leading software and solution provider. Interviewed by Dr. Pei Huang, Editor-in-Chief of e-works, Eplan CEO Mr. Sebastian Seitz shared the strategy of the sustainable growth of Eplan in August 2024. Mr. Bill Qin, Eplan Greater China President, also joined the interview.

Eplan CEO Mr. Sebastian Seitz

Eplan CEO Mr. Sebastian Seitz1. The unique competitive advantages

Founded in 1984, Eplan is part of the world's leading Friedhelm Loh Group and a sister company of RITTAL. The Friedhelm Loh Group was founded in 1961 and now has 12 production sites, 95 subsidiaries and 12,100 employees worldwide, with revenues of approximately 3 billion euros. Eplan is deeply engaged in the field of computer-aided automation design, providing leading software and service solutions in the field of electrical, automation and mechatronics engineering. With efficient engineering as its core value, EPLAN helps manufacturing companies to improve the efficiency while reducing the costs and achieve technological innovation.

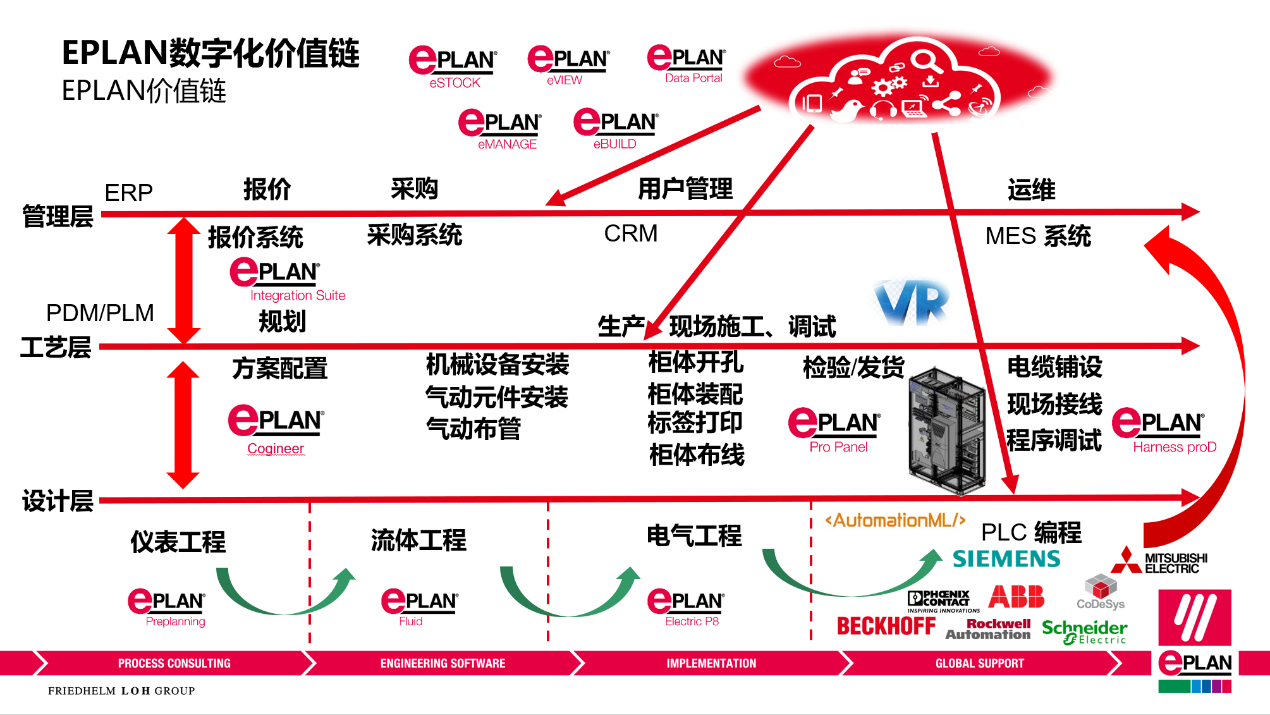

Technological innovation is an important driving factor for the prosperity of enterprises. Through the continuous investment of the global R&D team, Eplan has built an electrical engineering platform based on a unified data model, providing software solutions such as Eplan Electric P8, Eplan Pro Panel, Eplan Fluid, Eplan Preplanning, Eplan Data Portal, Eplan Harness (Cable) ProD. The portfolio comprehensively covers many fields of engineering such as electrical design, fluid design, instrumentation design, electrical manufacturing process design, field harness cable engineering, to help manufacturing enterprises with efficient engineering design and promote the digital transformation of the electrical industry.

Eplan software solutions

Eplan software solutionsThe globalization strategy is one of the key factors for its success. With branches in 39 countries around the world, Eplan has established an extensive and responsive service network. Combined with local professional teams and a global product platform, Eplan electrical engineering solutions have been widely applied across regions and industries, accelerating engineering efficiency and innovation for global customers.

In the field of automation design, Eplan is known for its model-based approach and standardization. The model-based approach can help users visualize, simulate and validate their designs, reducing modifications and rework. Besides, Eplan strictly complies to the standards across the globe to ensure consistency and high quality.

Mr. Seitz said that Eplan has maintained a strong growth. As an industry leader, Eplan is committed to providing customers with efficient, accurate, and automated electrical engineering solutions through technological innovation.

2. Keep standing in the forefront of the industry

By applying latest digital and intelligent technologies, Eplan has brought about a profound change in the industry. The increase of efficiency not only tackles the shortage of educated labor, but also largely reduces product costs and expand profit margins. For China's manufacturing industry, these technologies also provide a strong support for globalization. Eplan's advanced electrical engineering platform and solutions can "escort" enterprises to expand overseas and promote the global manufacturing to a standardized, efficient, intelligent and sustainable future.

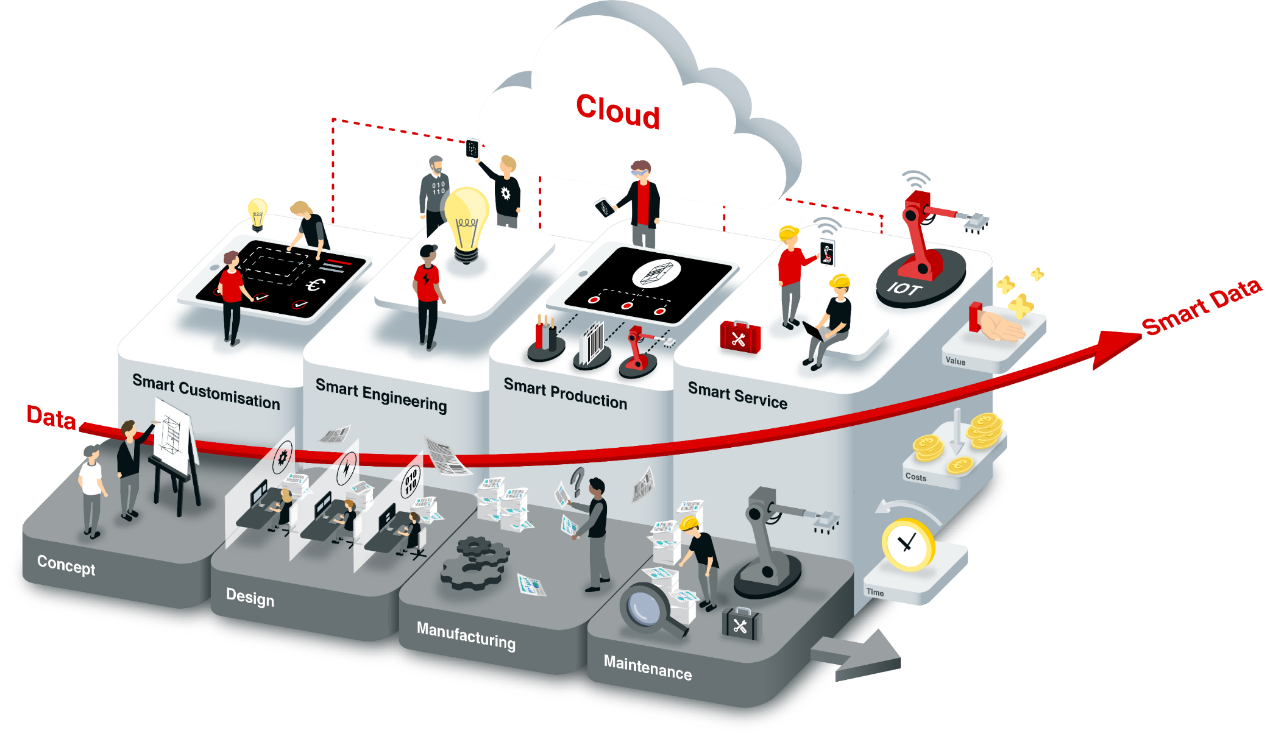

Eplan solutions from concept to maintenance

Eplan solutions from concept to maintenanceProduct innovation never stops in Eplan. The 2D and 3D integration, the cloud platform, and model-based schematic modeling are the three big milestones, which have not only reshaped the automated electrical design and manufacturing process, but also greatly improved the overall efficiency of the digital factory.

“Eplan offers a seamless integration of 2D and 3D design. Especially when it comes to panel design and switch gear design, we have integrated the schematics as well as the digital twin,” said Mr. Seitz. Together with AR technology, the system can instantly display internal structure and faulty components, improving fault detection and maintenance efficiency.

AR auxiliary wiring

AR auxiliary wiringEplan has launched a cloud-based collaboration platform, which provides a place for all participants in the entire ecosystem to work on one model across multiple sites, multiple entities, multiple customers or multiple participants. It significantly improves efficiency and reduces costs, while ensuring the consistency and accuracy of the design and manufacturing process. With Eplan Cloud, customers can realize global collaborative design through cloud-based services, which is a tremendous value for the entire chain.

At the same time, Eplan is working very hard to strengthen its core competency—fast modeling. Mr. Seitz hoped to deliver to be the fastest modeler for model-based schematic in the world, “we want to be at least 30 percent faster than any other tool in the world. I want to deliver to that promise.”

The digital twin, as a part of Eplan software, covers from concept to detailed design, and to manufacturing and operation. It meets the needs of different roles such as decision makers, manufacturers and operators.

Mr. Seitz emphasized that Eplan provides a fully integrated digital twin, which is not a special service and at no extra cost. It is used throughout the entire life cycle of the automation system design, cabinet configuration, manufacturing planning and operation and maintenance.

The core value of the digital twin model is that it can accurately reflect the connections between the complex actuators, sensors and control units inside a machine. Through the model, operators can clearly understand the position, function and interaction logic of each component, which provides the knowhow for virtual commissioning as well as operation and maintenance. They have quite a few use cases already.

Mr. Seitz took a robot arm as an example. Each action of the robot arm is based on the feedback of sensor signals and the precise control of the actuators. All the connection is based on the accuracy and reliability of schematics in Eplan software.

Eplan has made a lot of efforts on data consistency of the entire ecosystem. It is doing a lot of standardization together with the component manufacturers. Based on the data sharing and seamless integration through Eplan Project, it builds up an ecosystem network for efficient and collaborative innovation from component suppliers, module manufacturers, OEMs/system integrators to end users (owners).

EPLAN Industrial automation collaboration platform

EPLAN Industrial automation collaboration platformEplan has always followed a platform strategy. Mr. Seitz said that no matter which software packages the user chooses, in the backend it's one software on one data model. This one integrated platform not only improves the flexibility and scalability of the software, but also ensures the data consistency and efficient collaboration of users in different scenarios.

Besides, Eplan is successful in acquiring really good talents with industry know-how who know how automation systems need to be designed. “Try to have the best team really using the latest technology and bring this up to speed for the value of our customers with this integrated data model is really unique from my point of view,” said Mr. Seitz.

3. From technology to industry, Eplan’s new explorations

Mr. Seitz believes that the more familiar customers get with the model-based approach the more advanced in deciding their automation products. And the creation of the automation system will become a big issue. With the rapid development of AI and machine learning, electric engineers’ routine work will be revolutionized. Therefore, Eplan is working to develop more intelligent automated engineering systems that are designed to accelerate innovative design processes and respond to rapid changes in requirements through automatic reuse of existing organizational process assets.

Moreover, the spread of cloud computing has expanded the application of automated electrical engineering software. Cloud computing not only offers flexible methods for data storage and access, but also facilitates resource sharing and collaboration. Now Eplan has some modules that are purely offered as a SaaS model. These cloud-native modules provide users with a more convenient and efficient design experience. On the other hand, Eplan's core platform adopts a subscription model which reduces initial costs for users to utilize advanced design tools. The subscription model will deliver faster software feature updates.

The industrial automation and the transformation of the energy industry brought high demand of automated electrical engineering software in the global market. The industrial automation industry from automation system to the entire smart factory, all need software support for automation design. In the energy industry, with the acceleration of global energy transformation, smart grid and renewable energy have become a focus for many countries. Grid operators are in urgent need of advanced planning and engineering tools to ensure the intelligent and efficient operation. Eplan provides pre-configured industry samples and efficient solutions for the design and operation and maintenance of key facilities such as power transmission and distribution stations and data centers, significantly improving design efficiency and accuracy and meeting the needs for efficient design and reliable operation and maintenance.

4. Open multi-dimensional evolution

Facing the diversified needs of the market, Eplan shows a high degree of flexibility and strategic vision. By embracing digitalization, enhancing data integration and standardization, EPLAN lays a solid foundation for customers to build smart and efficient factories. Eplan attaches great importance to the partnership ecosystem and integrates industry resources to jointly provide customers with all-round and high-quality solutions.

- Continuous investment in digital factories

- As a big and complex issue, digital factories require efforts and cooperation from various sides. “I think what we are really working hard on and investing is being able to deliver a piece of ‘puzzle’ from Eplan that fits into the virtual model of an entire factory. We can really be able to deliver this information in a way in an environment that really simulates a digital factory,” said Mr. Seitz.

- In the early stage of a smart factory, a detailed and accurate digital model is expected to solve many potential problems. “But it's a complicated thing. I think all the related parts should work towards this direction and have open standards so that we can integrate all the special solutions that are necessary,” Seitz pointed out. Different solutions will be needed to deal with different issues, such as energy consumption, air consumption and electrical connection etc.

- Eplan has a clear and long-term plan for it. Seitz made it clear that Eplan has important products and services and will provide this in an open way to make this vision happen. He understands that the smart factory will not happen overnight, it will require the entire ecosystem to work together, and Eplan is willing to be an integral part of this process.

- Promote data integration and standardization

- Eplan is actively pushing industry standards such as eCl@ss and AAS (Asset Administration Shell) to promote data consistency and data integrity. They are promoting standardization also by setting some standards with Data Portal.

- Eplan Data Portal is a professional online component platform, which provides high-quality engineering data for users worldwide. It can greatly improve the efficiency and quality of engineering design. Currently, more than 450 component manufacturers around the world have put their component data on the platform, including 114 from China. There are more than 2 million parts on the platform, where the design needs of global users can be accurately connected, increasing the sales of components and devices of manufacturers.

- As for the cost, the component manufacturers have to invest a little bit in the data acquisition and preparation. High-quality data is the key to increasing market acceptance. Mr. Seitz said that Eplan has a separate team to ensure a basic set of quality and the accuracy of the data. They help customers to understand and set up in the right way and automatically upload their data to the Data Portal. The effort the component manufacturers need to take is taking care of their own data.

Eplan digital electrical engineering solution

Eplan digital electrical engineering solutionFor the data silos in manufacturing companies, Eplan Integration Suite can integrate mainstream ERP, PDM and PLM systems to help users optimize their workflows. Besides the integration to ERP/PLM and other systems, it provides especially the integration with electrical BOM, which effectively provides the accuracy of procurement information. Mr. Seitz also stressed that a complete product BOM should include the electrical BOM and the mechanical BOM.

According to him, Eplan eMANAGE enables data sharing quickly and safely with colleagues, partners, suppliers and customers. Unlike PDM/PLM companies, Eplan is trying to be a standard software company, said him.

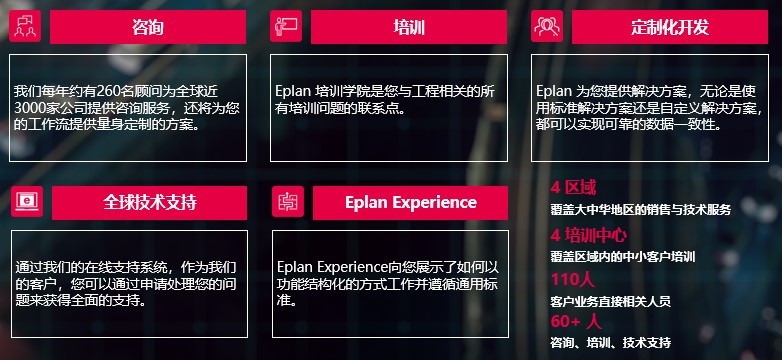

- Grow together with Chinese market

- In order to provide better service in Chinese market, Eplan has built a local team and is increasing its investment, aiming to deeply understand customer needs and provide customized solutions. Mr. Seitz believes that although China is undergoing adjustments, the market size of China's manufacturing and energy is huge. Currently, the adoption rate of electrical automation software in China is still very low and Eplan still has huge room for growth in this market. On the other hand, Chinese industry leaders are accelerating their globalization and building new factories overseas. Relying on deep industry knowledge, technology accumulation, and a deep understanding of customer needs, Eplan will continue to help Chinese customers significantly improve the efficiency of the entire manufacturing process as well as the level of intelligent manufacturing .

Eplan’s local service in China

Eplan’s local service in ChinaMr. Seitz also highlighted Eplan's unique differentiation advantages in electrical design. Eplan ensures accuracy and long-term availability of electrical documentation, which is critical for machinery with long production cycles and demanding maintenance requirements. A mechanical part may be iterated many times, but electrical design will become increasingly valuable through time, which is the key to Eplan's long-term customer trust.

Eplan follows a market-oriented approach for customized software development. Mr. Seitz pointed out that if there are indeed special requirements that are only valid for China, Eplan is open to develop it locally to meet customer’s requirements. For example, they have done some customizations for EATON Changzhou.

- Expand ecosystem network

- Most of the well-known PDM/PLM vendors are partners of Eplan, including the big component manufacturers like Siemens, Rockwell, Phoenix Contact, Weidmüller, and Lenze. They are further divided into strategic partners and technology partners, among which Siemens, Rockwell and Rittal are strategic partners and join product development. Then most of the technology partners are integration partners for software and hardware integration. For example Gossen Metrawatt in measuring instruments, they have an integration to Eplan. Eplan is also actively expanding its partner ecosystem in China.

Eplan global partner network

Eplan global partner networkPostscript

From physics background to PLM work experience, from starting his own business to joining Eplan, Mr. Seitz has a wealth of industry experience. Under his leadership, Eplan has successfully transformed the traditional perpetual license model to a more flexible and sustainable subscription model, achieving average growth rates of over 15%, especially in key markets such as China and the United States, where the growth is significantly higher than the average. Eplan successfully grasps the industry and technology development trend, leading the new wave of development for global electrical automation engineering software.

Looking ahead, as digital transformation of the global manufacturing and energy industries accelerates Eplan is embracing new growth opportunities. Mr. Seitz stressed that Eplan will continue to deepen its expertise in the field of electrical engineering and automation to provide customers with more flexible and efficient automation design solutions and services.

and Dr. Pei Huang (Right)20241127104340.png) Mr. Sebastian Seitz (Left) and Dr. Pei Huang (Right)

Mr. Sebastian Seitz (Left) and Dr. Pei Huang (Right)