CD-adapco:help Chinese customers realize

On December 9 2013, the two-day STAR 2013 China User Conference was unveiled in Shanghai. It is CD-adapco's first user conference in China. A team of more than 30 CD-adapco people composed of global executives and support engineers present the conference.

e-works: Please introduce CD-adapco.

Jean-Claude Ercolanelli: CD-adapco has a history of more than 30 years, providing engineering simulation software, technical support, and consulting services. We have a vision to become the market leader of multidisciplinary simulation and our product STAR-CCM+ will become the CAE best-in-class tool in the coming years. Our solution STAR-CCM+ is a multidisciplinary product, which means that we can solve for multiple physics, flow dynamic, stress, electromagnetism, chemical reactions with one product, one license, and one user interface. One of our differentiations with competitors is that we are not only a product or software but a package, it's a package that we provide to people, software, and the engineering knowledge on how to use the software, on how to engineer the product using our software.

CD-adapco has about 850 people and about 35 offices around the world. These 850 people will patiently aid their customers to solve their engineering challenges about the use of simulations thus reduce the time and cost.

Stephen Mcilwain: Each of our office in each country has a support team of engineers to support the customers in that region. Those engineers are qualified from universities with master degree, PhD. some of those engineers also come from industry with rich experience in industry. We leverage their knowledge to support the customers in aerospace, marine, automotive, electronics etc.

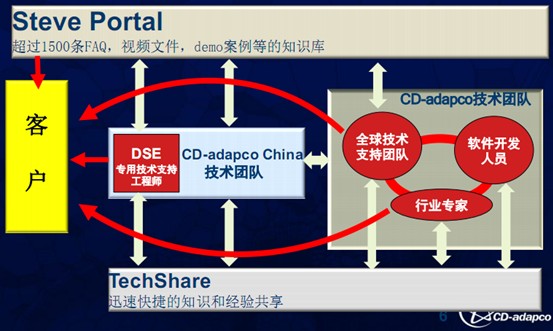

Customers can also access Steve Portal to get support. Steve Portal is CD-adapco's customer knowledge base with more than 1, 500 of engineering answers, videos, and case scenarios to common problem that people are trying to solve with our software. The real value of technical support is being able to contact a dedicated support engineer (DSE), so our customers can talk to that engineer directly. CD-adapco has established a very close relationship with our customers through that DSE model.

CD-adapco Customer Service Strategy

Sven Enger: We have two different supporting groups. One group is specialists of application, another group of people are industry focused. We have people focused on automotive of ground transportation, aerospace and defense, chemical process industry, electronics, life sciences, energy, and marine industry. This group of people has normally worked numbers of years in these industries within one of the leading company. They know their own industry very well and they understand what kind of technical requirements the industries are having. They help on one side DSE team to be more successful and efficient in their approach and in this industry. On the other side they help feeding information back to product development team, so that CD-adapco is able to develop the right and advanced tool for the industries.

CD-adapco's software development team need to talk to support team to understand customer needs and at the same time they need to talk to industry specialists to know what is our next feature. The two components make us the product roadmap. We have 3 major versions every year,that is why we are so convinced about ourselves and our ability to really become the market leader.

STAR-CCM+ Update Timeline

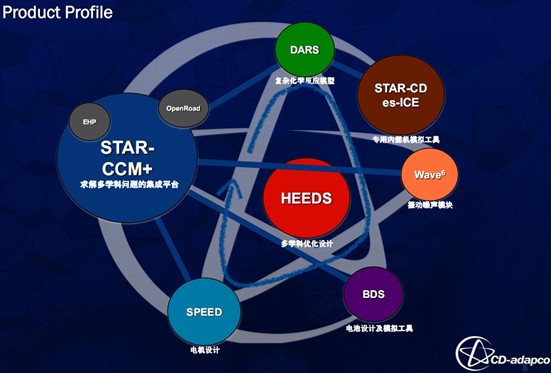

e-works: What's CD-adapco's product strategy in project simulation?

Jean-Claude Ercolanelli: CD-adapco's flagship product is STAR-CCM+. It is not only a CFD solver, but also an integrated platform to help customers to solve multi-physics and multidisciplinary issues within one single environment, such as battery, aerodynamic-vibration-acoustics, casting, chemical reaction, combustion, fluid structure interaction, and design optimization. Therefore, STAR-CCM+ is called multidisciplinary, multi-physics systematic simulation or collaboration simulation. CD-adapco has always been focusing on simulate the real world.

STAR-CCM+ can integrate with many other tools like DARS. It is used for analyzing complex chemical reaction and modeling. With DARS, STAR-CCM+ can integrate with STAR-CD and can provide a complete solution for chemical reaction modeling. The battery design and simulation tool Battery Design Studio (BDS) can serve for electrical or hybrid electrical vehicles and commercial aircrafts. With STAR-CCM+ and BDS, users can calculate 3D thermal property in different length scales, fluid property, and electrochemical property. In order to enhance our electrical motor design capabilities, CD-adapco acquired the leading electrical design product SPEED in 2011. With the combination of STAR-CCM+ and SPEED, customers can use electromagnetic analysis, flow fluid analysis, and thermal field analysis. Besides, there is noise and vibration analysis module Wave6.

CD-adapco Products

Multidisciplinary optimization design platform HEEDS offers a unique optimization engineering solution which can both do multidisciplinary engineering analysis and optimization. The integration of optimization and design development with simulation helps optimization in the early stage of design thus CAD models can connect directly with optimized design. It is more efficient. In addition, HEEDS can connect with other multi-physics tools like abaqus and Ansys Mechanical and add what is missing in STAR-CCM+. It is very important for users that HEEDS can help them create interfaces with other fluid dynamics tools.

e-works: What are the competitive advantages of STAR-CCM+ compared with other fluid analysis software?

Jean-Claude Ercolanelli: Firstly, STAR-CCM+ is a new generation and is written in C++ on client server architectures. That helps us massively processing the codes. Based on java systems, simulation analysis process is completely automated. Therefore, the time spent on simulation is smaller within STAR-CCM+ than other products.

Another advantage of STAR-CCM+ is the meshing process, which is the step from CAD to mesh. It's a process that may take weeks in other tools but it only takes hours or a day in STAR-CCM+. Usually, meshing process is the most time consuming process in CFD. The process of CAD to mesh is largely automated in STAR-CCM+, so time is bringing to the users.

In terms of usability, STAR-CCM+ provides one single integrated environment where with the same user interface for CAD, mesh, fluid, and force processing, so it is much easier and quicker for users to learn and use. Many users can engineer according to their customer feedback and more and more students and engineers are learning to use STAR-CCM+.

Finally, STAR-CCM+ updates every four months to guarantee user's benefit. It releases three versions every year with enhancements and new functions.

e-works: How does CD-adapco help users in their practical work if they meet difficulties?

Stephen Mcilwain: CD-adapco has dedicated support engineers to answer all the questions our customers have. For every customer, we have one dedicated support engineer (DSE). That engineer will go to the customer and they will stay with the customer for days to explain and help and promote the use of software in their engineering process. Being an DSE in CD-adapco, it's very important for all. It's the person that behind 850 people and convey the message and knowledge and share that with customer.

At the same time, a DSE hears, listens, and learns from the user what he wants to do. They are also responsible to convey that to software development team. Therefore, we can improve the software and the next version can be better.

e-works: It is the first year that CD-adapco coming into Chinese market as original vendor, so what will you do for Chinese customers?

Jun Liu: In the end of 2012, CD-adapco founded our office in Shanghai. We entered Chinese market as original vendor. Now in China we have 22 people and among them 12 are engineers. They can communicate with engineers in other countries and bring the global engineering experience to China. CD-adapco will open Beijing office in early 2014. At that time, CD-adapco will have 50 people serving Chinese market. Most importantly, beyond us there is more people supporting us from the global support team, industry and development experts. They will provide the latest technology support and bring the global advanced industry knowhow and simulation skills to China.

In February 2014, CD-adapco will have Chinese version software. We are working actively to penetrating to China. We are localizing our user interface and then we will localize our user documentation. CD-adapco's Chinese website is going to be open soon. Besides, We also developed a lot of training materials in the last few years. All of that material is available to all CD-adapco customers.

e-works: What's the outlook of CD-adapco in Chinese market?

Jun Liu: As you know, CFD software like FLUENT and CFX have taken a big market share in China now, but we still have confidence in our products. The reason we come to China is we want directly doing this technique and software to Chinese customer. I'm quite sure we can reach their market share in two years because of our better products and better global support.

For Chinese version, please click here.