JDA: Help Worldwide Companies Build All-win Strategy in Supply Chain

On July 11 2013, I attended JDA 2013 APAC Supply Chain Innovation Forum and interviewed JDA President and CEO Mr. Hamish Brewer. Mr. Brewer shared his view on challenges that e-commerce brings to Chinese manufacturing and retailing industry, and also strategies against these challenges. He introduced JDA's new integrated supply chain solutions after the merger with Red Prairie and also new features of JDA eight and cloud service strategy.

Mr. Hamish Brewer, JDA President and CEO

1. JDA helps companies win e-commerce challenges

Pei Huang: Right now, Chinese e-commerce is growing rapidly. What's your view on e-business changes the traditional manufacturing and retail industry? How should companies overcome these challenges? Are there any best practices in other countries?

Hamish Brewer: e-Commerce definitely represents a change for both manufacturers and retailers of different magnitudes.

For retailers, ultimately it represents an existential challenge, which means some of them won't make it. We've already seen that in the U.S. Some of them failed to adjust to the pace of change of consumer expectations. Today leading players in the market place, like Amazon, do not have profit as the first objective, just grabbing market share with low margins, or even without making money. It can be very difficult for traditional retailers to respond to that type of competition.

Mr. Hamish Brewer delivering keynote speech

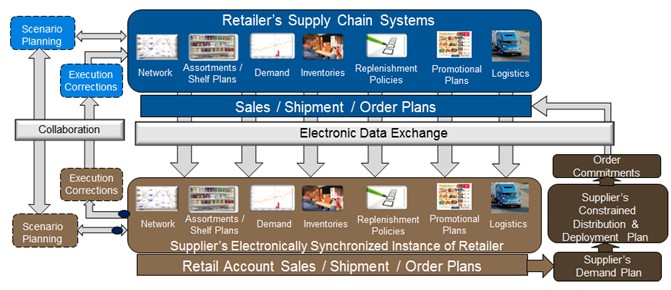

JDA Collaborative Supply Chain Strategy & Execution

However, that's not the biggest issue for traditional retail market. The biggest issue is really going to be the shifting consumer expectations. Today, consumers are not going to accept the traditional responses of a retailer to provide goods and services where and when they want them. It's actually more difficult to integrate traditional retail channel with online experience than just providing online services. Consumers are hoping to get uniform experience whether they are on the website, or standing in the store, or using mobile devices, or calling into a call center to get customer services. Those retailers adjust and integrate online shopping experience with in-store experience well, can be very successful in business, because plenty of evidence have shown that consumers still want to go and visit retail stores, They don't want to do everything online. Actually, retail stores are not going away but are changing and consumers expect that employees working in the store are connected, because they know what's going on, They know what consumers are putting in their shopping baskets, they knew how to response to competitive price challenges and things like that. But today, most employees working in retail stores don't have that information, and they are out of touch with what's going on in the online world. So, there's a lot of work to be done for the retailers. The supply chain to support that work inside the retails has to change fundamentally. Retailers in general have spent the last several decades building a supply chain that is designed to deliver cases and pallets to the shelf at the lowest cost per case. Now, we have completely different paradigm of performing picking, whether in the store or in the warehouse, and the supply chains of the retails were never designed for that, now retailers have to re-do or re-design supply chain to efficiently deliver the multi-channel converses experience profitably. JDA has being focusing on developing our solutions to support retailers to run the multi-channel businesses profitably.

For manufacturers, that challenge will affect the manufactures as well, because retailer is going to start to drive virtual assortment strategies. If I want to compete with Amazon, I can't be limited to the assortment just existed in my store. I need to be able to sell much bigger virtual assortment. It doesn't certainly means retailers going to hold all that inventory, but manufactures have to be part of the supply chain, because there would be certain products that retailer want to be available for sale, but may be never in-stock. So the retailer is going to be work collaboratively with manufacturers to make sure that service level that retailers want to deliver are achievable, even though the retailer never hold inventory.

More importantly for manufacturers, e-commerce environment brings more opportunity than threat. e-Commerce environment creates an opportunity for manufacturers to become connected with the consumer, in a way that has been very difficult in the past. Now the manufacture can have a direct relationship with consumer of the product, whether that relationship is an informational relationship through social media, or that relationship is a transactional relationship through buying directly from manufacturer. Whatever the approach, the world of e-commerce is going to disrupt to some degree the historical barriers that exist between manufacturer and consumer. Manufacturers are going to get a lot closer to the consumer. They are going to understand what consumer is buying and why, where, and when, and use that information to drive product development, manufacturing, capacity planning, strategies, distribution, and inventory holding strategies. It's going to change the game for manufacturers.

Huang: Chinese e-commerce platform Taobao and Tmall hosted an "11·11 Shopping Carnival" in 2012 and sales revenue achieved 1.91 billion yuan. For manufactures, many of them are short of production capacity when large orders come in festivals, so how can a new supply chain solution solve this problem?

Brewer: This is not a new problem. All countries have festivals of some kind. The volume of sales occurred when those festivals are happening. Nobody wants to build capacity to be able to response to that volume, because for them for most of the year, they would have massive spare capacity. The question is first how do you build as far as possible an accurate plan forecast for what's going to happen. Secondly, how do you optimize the balance between the responsiveness in supply chain and cost effectiveness?

JDA has many years experience in dealing with these problems. We help companies create pre-season forecast ability so they can build up the inventory they need cost-efficiently and distribute it cost-efficiently. So it is available when the festival happens, and don't need emergency manufacturing or contract manufacturing. This is basically a demand-supply challenge. For example, Mars, one of JDA customers who have a few key seasons in the year when people buy a lot of chocolate. In the West, we have Easter. Traditionally, in Easter, people buy a lot of chocolate over a period about one week. Mars is never going to build capacity in their manufacturing plants to achieve that. Actually, Mars starts building product for the Easter Week about six months before that happens. When the time comes, all the inventory they need is in the places they need it, in the right volumes, so they can then very quickly service the market place, not own too much stock nor do they loss too much sales. It's a challenge doing that kind of season pre-built, but JDA has spent a long time working with that kind of companies to solve that problem with pretty sophisticated planning.

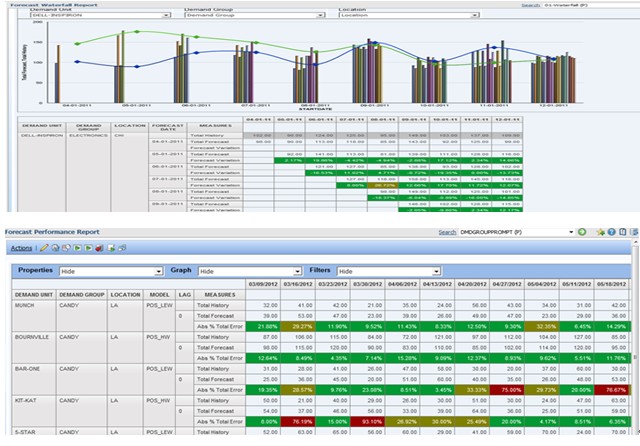

JDA Forecast Waterfall Report and Forecast Performance Report

Huang: Right now, many manufacturers are thinking building their own e-business platforms, but they have two choices—build it by themselves or by the third parties. What's your advice for them?

Brewer: From the experience in the U.S., this is a maturity cycle. The first phase of the maturity cycle is that most companies are going to leverage the shared platform or the third-party platform, because they can achieve volume quickly. Second stage of development, which in my view is underway now in the U.S. probably for about two or three years, is that the retailers in particular are starting to realize that the third-party platform leads to the elimination of differentiation. If they are going to be able to provide differentiated consumer experience at the end of the day, they cannot outsource it. It needs to be part of the core business. So what's we've seen in the last two to three years is that people used to be on Amazon are now taking it in-house and integrating it into the core of their business. I imagine that development cycle will similarly occur in the future in China as well. The issue of self-owned platform is not just about the shopping portal but the supply chain supported abilities behind it, like same-day delivery, timely notification for customers, and accelerated speed of service to customers. It's much more of supply chain investment than frontend web experience.

Huang: If a company needs a complete B2B online platform and needs to provide logistics service for buyers and sellers behind the platform, can JDA offer a complete solution?

Brewer: I think we can offer that but it's not everything that they would need, for example they still need an ERP system to process orders and do finance, but in terms of managing e-commerce business, for managing inventory, customer orders, front end web presents, and 3rd party distribution networks, JDA can do all of that and have a lot of experience doing that.

In the past, companies built their own B2B platforms.If you think about companies like Amazon and eBay, who acted as the first movers of the market place, they really had to build all their own technology because the solutions didn't exist by then. As times going on, the packaged software industry has called out. JDA now has very broad range of solutions that can support any business from multi-channel demand planning, multi-channel fulfillment planning, customer order, distributed order management, customer segmentation, customer level pricing, etc., but we never had those 10 years ago. The packaged software business is capable of supporting most of the requirements of the e-business. I anticipate that we will see more and more new business models emerging and those companies will buy packaged software tools to support their business models, because building the system all by themselves every single time is not the most efficient way.

Many core functional requirements of e-business are going to be the same, such as demand forecasting, network distribution management, creation of consumer orders or B2B orders depending on business model, promising inventory to those orders, and optimizing allocation of the existing inventory to existing order pools. There may be some nuances around how to use social media, customer data to create a community within customers based on different types of business models, but the basic core of these businesses is fairly similar. That's a great opportunity for JDA because all of these different types of e-businesses whether they are stand-alone e-commerce businesses or multi-channel businesses with e-business and physical business working together, JDA can provide appropriate solutions for each of them.

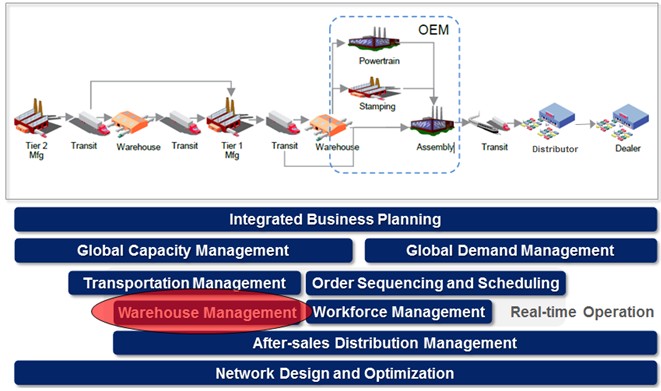

JDA End-to-End Supply Chain Solution

2. Unique JDA Cloud—changing on demand

Huang: Chinese government are now promoting cloud computing technology heavily, but on the other hand there are not so many successful cloud computing applications. Is JDA Cloud Solutions fit for Chinese enterprises? How about its security measures?

Brewer: I think firstly we need to ask ourselves what we are trying to achieve with cloud. When people say SaaS, they think of subscription, because a traditional aspect of most SaaS software companies instead of buying a license with a maintenance charge and paying for hardware and consulting services, they just get all as one and pay at monthly basis for services. So people think SaaS equals subscription in general. In fact, JDA Cloud service can be purchased through both subscription and traditional license feed. The reason we do both is we believe as the market for SaaS matures, companies are going to realize how you buy your right to use the intellectual property is really nothing to do with the benefit of cloud. It's still same service you are buying. It's just the question how you buy the right to access it. Customers can buy license or do expense monthly. We want to give our customers a choice. Besides, they don't have to buy equipment and host themselves when buying JDA Cloud. We will provide the equipment, database, and technology stack, run and maintain it for customers. JDA also supports customers own their own private cloud. The key value proposition of JDA's cloud offering is excellent supply chain experts who know JDA products better than anyone else in the world, and can run the solution for customer better than they can. JDA Cloud can provide customers extreme configurability so they can customize the systems based on their requirements. We have built some very unique architectures to be able to do that. The biggest value is, JDA customers can get real time continuous upgrades. Once they buy JDA cloud as a service they don't have to worry about upgrading the supply chain systems again.

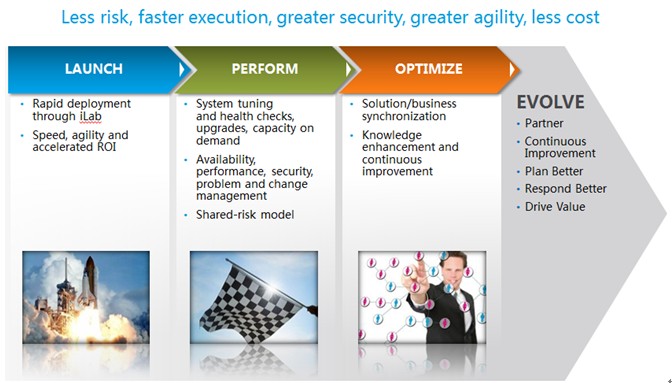

JDA Cloud Service Offerings

3. Breaking silo thinking and realizing integration from supply chain planning to execution

Huang: After being merged with Red Prairie, what functions have been enhanced? Is there any overlapped functions? How is JDA going to integrate these solutions?

Brewer: After the merger of JDA and Red Prairie, JDA's 2012 revenue exceeded over 1 billion dollars and became a leader in supply chain management market around the world. The major areas Red Prairie adds to JDA first of all is supply chain execution and warehouse management capabilities, which was obviously a hole in the JDA footprint. After the combination, JDA's supply chain execution functions are strongly enhanced. Red Prairie also brings very strong set of workforce and labor management capabilities. The third area of importance is multi-channel commerce, because Red Prairie had developed a number of all channel commerce solution offerings through acquisitions and internal development. There are a number of major solution areas that Red Prairie really brings a lot of additional value. Integration of supply chain planning with supply chain execution may create a lot of opportunities for JDA.

For example, many enterprises have picking order but traditional supply chain execution system can't complete the picking order. Today people in the warehouse have to make the decision themselves. Tomorrow, with JDA, supply chain execution system can interact with planning system. Distribution instructions will instruct the warehouse to change the picking instructions and change supply chain plan dynamically. JDA is going to be able to really build interactions between planning and execution, between warehousing transportation, demand planning, order planning, etc. These solutions work together seamlessly, and going to bring more opportunities for JDA to create new ways to improve supply chain efficiency.

Huang: Can you introduce the innovations JDA eight brought to the supply chain management?

Brewer: It has been a lot of silo thinking in the traditional supply chain management solutions. There are single functional modules like transportation, warehouse, demand planning, fulfillment planning, manufacturing sequencing in the supply chain. The truth is all these disciplines are not really interconnected. Through the integration of products that acquired from i2, Manugistics, and JDA had beforehand, and Red Prairie had, we are really built as islands of capability functionality, or so called silo thinking. JDA eight has broken the traditional silo thinking across the supply chain. The value of JDA eight now is not just the technical integration but also the process integration. Now JDA eight can help our customers create workflows across boundaries of the traditional products and help them create and deploy workflow that goes from demand planning, transportation planning, to distribution planning and realize end-to-end supply chain planning process. JDA eight is very simple and easy to use. With good extendibility, it offers a better user experience, built-in analysis tools and real-time supply chain collaboration. JDA eight is the world’s most comprehensive supply chain suites, it has more than 30 products offering and provides cloud environment and support mobile applications.

JDA Solutions with Extensive Value Chain

Huang: How do you think the maturity of Chinese supply chain market?

Brewer: The awareness of supply chain management is increasing significantly in China. Chinese labor elements and cost of goods are going up faster than other countries in developing world. All of the companies in China are going to deal with a conflict between on the one hand the policy is driving labor cost; on the other hand they want to provide a competitive manufacturing platform for companies around the world. The only way to bridge that gap is to improve productivity per capita of the labor inside the Chinese companies. One of the key ways that JDA can help Chinese companies is increasing supply chain performance, focused on productivity per person, and business operation efficiency to support the increasing labor cost without reducing capacity. So JDA has a lot of opportunities in Chinese market.

Dr. Huang Interviewing with Mr. Hamish Brewer

Dr. Huang and Mr. Hamish Brewer