e-works organizes 2024 Industry 4.0 delegation to Germany and France

e-works successfully organized the 2024 German-French Industry 4.0 delegation in April 2024.

During the 11 days, e-works CEO Dr. Pei Huang, together with more than 20 Chinese enterprise executives visited many leading enterprises in Germany and France, including CLAAS, Schneider Electric, Dassault Systemes, WAGO, Phoenix Contact, Schunk, SICK, ifm, and Volkswagen and a global leading industrial trade fair to deeply experience both the latest developments of manufacturing industry as well as the intelligent manufacturing trends in France and Germany. The delegation members visited different factories, attended the Hannover fair, listened to many technical lectures and exchanged ideas with different people, making this a "fruitful" journey of thinking and learning.

The delegation before the Paris City Hall

The delegation before the Paris City Hall

The first stop was the CLAAS Tractor Le Mans factory. CLAAS is a world-renowned manufacturer of agricultural machinery and agricultural vehicles. Founded in 1913, CLAAS expanded its business into 150 countries, with factories in 19 countries, including one in Shandong. In recent years, the Le Mans factory has been greatly renovated in order to meet the very complex product configuration needs from the agricultural machinery market.

In the workshop, the delegation watched the processes of power transmission system assembly, cab assembly, final assembly, painting and final check. Le Mans factory produces five different series of tractors and is actively promoting intelligent logistics and automation. CLAAS has made full use of Dassault Systemes' digital solution and factory simulation platform. The introduction of AGVs also made the production process more flexible.

Group photo at CLAAS

Group photo at CLAAS

The second stop was the headquarters of Schneider Electric, a global leader in energy efficiency management. As one of the world's leading suppliers of energy management and industrial automation solutions, Schneider Electric provides global enterprises with digital transformation solutions in plant operation optimization, equipment management, and industrial control and safety. The IoT-based EcoStruxure platform provides customers with safe, reliable, efficient, sustainable and interconnected energy management solutions.

Ms. Isabelle Zhang, Director of Business Development at Schneider Electric, and Mr. Jean-Baptiste Fischer, Schneider Industrial Digital Transformation Director, warmly received the delegation at the Innovation Hub and introduced the development history and corporate culture, sustainable development, and typical cases of helping industrial enterprises in realizing intelligent manufacturing. They also shared the of construction of Schneider Electric lighthouse factory as well as the digital transformation services provided by Schneider Electric.

Group photo at Schneider Electric

Group photo at Schneider Electric

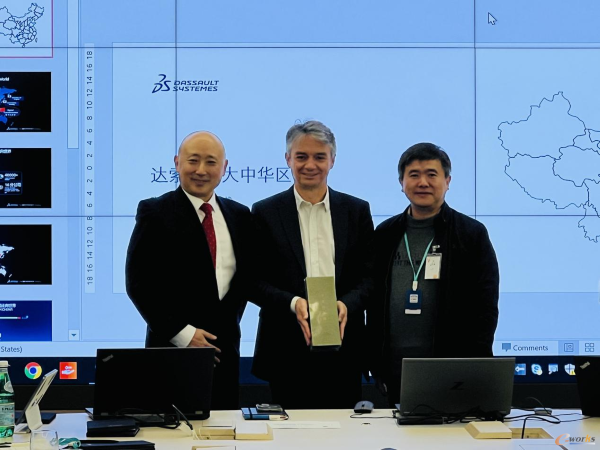

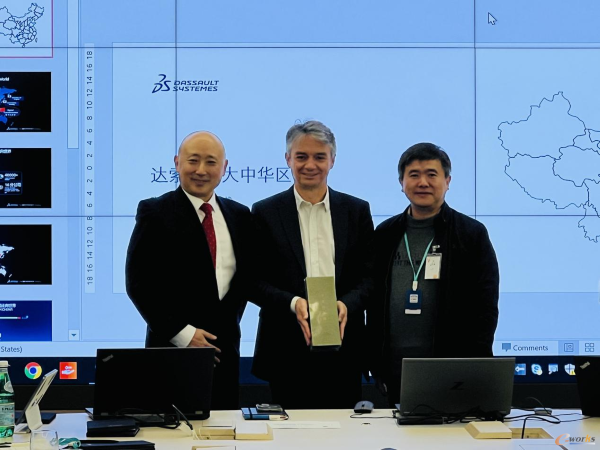

The third stop is the global industrial software giant Dassault Systemes. Mr. Pascal Daloz, CEO of Dassault Systemes, Mr. Ying Zhang, President of Greater China, and other senior executives warmly received the delegation.

Founded in 1981, Dassault Systemes is the world's leading provider of 3D design software, 3D Digital Mock-Up and product lifecycle management (PLM) solutions. For more than 40 years, Dassault Systemes has empowered businesses with its 3DEXPERIENCE platform and virtual twin technology and formed a rich portfolio that enables innovation throughout the entire product lifecycle.

Dr. Pei Huang (right) with Mr. Pascal Daloz (middle) and Mr. Ying Zhang (left)

Dr. Pei Huang (right) with Mr. Pascal Daloz (middle) and Mr. Ying Zhang (left)

The fourth stop is the Autostadt and the Volkswagen Wolfsburg plant. Autostadt is the world's first and one of the largest automotive theme parks and service centers. The delegation learned about the history of the automobile and the development of the Volkswagen Group and its various brands, and felt the Volkswagen culture behind the hard steel shell and the mechanical structure. With more than 20 kilometers of automated assembly line and over 6,000 robots, Volkswagen Wolfsburg plant can realize mixed line production of different models of different brands. Here every 16 seconds a car rolls off the line, and the annual output amounts to about 1 million.

Volkswagen Wolfsburg plant

Volkswagen Wolfsburg plant

The fifth stop, the delegation came to one of the world's most influential industrial fairs, Hannover Messe 2024. The members stopped and explored at different stands to get a deep understanding of the latest trends and cutting-edge technologies in industrial development. With the theme of "Energizing a Sustainable Industry", this year the fair focuses on Industry 4.0, artificial intelligence, 5G, electrical engineering, mechanical engineering, energy supply and other fields, attracting more than 4,000 exhibitors from more than 60 countries and regions. This is also e-works' 10th visit to Hannover Messe since 2014.

The sixth stop, the delegation visited WAGO in Minden, a technology pioneer in the field of electrical connections. Led by the Vice President Thomas Mohring, the delegation visited the production line of injection molding, stamping and assembly, mold processing and repair workshop, and the performance testing laboratory. Founded in 1951, WAGO implemented the concept of using spring pressure instead of screws to connect conductors and now has 7 production sites around the world, including the Tianjin plant. As a leader in electrical connection technology, WAGO always adheres to the ultimate pursuit of product quality.

The sixth stop, the delegation visited WAGO in Minden, a technology pioneer in the field of electrical connections. Led by the Vice President Thomas Mohring, the delegation visited the production line of injection molding, stamping and assembly, mold processing and repair workshop, and the performance testing laboratory. Founded in 1951, WAGO implemented the concept of using spring pressure instead of screws to connect conductors and now has 7 production sites around the world, including the Tianjin plant. As a leader in electrical connection technology, WAGO always adheres to the ultimate pursuit of product quality.

In the performance testing laboratory, Thomas demonstrated many test projects such as durability test, current cycle test, temperature rise test, flame retardant test, overcurrent test, vibration test, which not only ensure the product quality and performance, but also reflects WAGO's responsible attitude towards the user.

Group photo at WAGO

Group photo at WAGO

The seventh stop was Phoenix Contact, a hidden champion of global electrical manufacturing. By implementing the strategy of "Empowering the All Electric Society", Phoenix Contact is now leveraging their products, digital technologies and solutions to improve the efficiency of production, storage, transmission and use of green energy, enabling the sustainable development of society. The delegation visited the All Electric Society Park, experienced various scenarios of photovoltaic, wind power, heat exchange and electric vehicles, and learned the implementation plan of intelligent control of the power grid. Through augmented reality technology, Phoenix Contact visualized the energy conversion process and made it available for interactive experiences, giving members a deeper understanding of green, energy saving and sustainable development.

Group photo at Phoenix Contact

Group photo at Phoenix Contact

The eighth stop is Schunk, a global leader in toolholding and workholding, gripping technology and automation technology. Mr. Sebastian Höpfl, Executive Vice President of Schunk hosted the delegation. Founded in 1945 by Friedrich Schunk as a small mechanical workshop, Schunk has now evolved into an international technology company with around 3,700 employees in more than 50 countries. Their products have been widely used in a wide range of industries including automotive, electronics, life sciences, aerospace and logistics. The delegation watched the flexible automated assembly lines in the assembly workshop and various grasping technology applications in the Colab, and had in-depth exchanges with Schunk senior executives.

Group photo at Schunk

Group photo at Schunk

The ninth stop is SICK, a world-renowned provider of industrial sensor solutions, where Mr. Markus Scaglioso, Senior Vice President, received the delegation and introduced the development of SICK. After 78 years of continuous innovation and development, SICK has become a very influential smart sensor solution provider worldwide in the field of factory automation, logistics automation and process automation with products widely applied in safety and protection, measurement, positioning, monitoring, identification, and detection. Experts from SICK introduced applications of sensors in flexible automation production line, and the application scenarios and cases of AI-based intelligent sensor, demonstrated the different outdoor sensors in the field, as well as different cases leveraging augmented reality technology.

Group photo at SICK

Group photo at SICK

The final stop was ifm, a hidden champion of electronic sensor industry. Founded in 1969, ifm is one of the leading manufacturers of electronic sensors, providing a wide range of intelligent sensors, distributed modules, controllers, software and system solutions to users with quality services to help them realize intelligent manufacturing and digital transformation. At the ifm R&D and production site in Tettnang, Mr. Frank Watzlawik, ifm Technical Officer Human Resources, once again warmly received the delegation. ifm attaches great importance to product quality and offers a five-year warranty, which is far higher than the industry standard. At ifm, every sensor is subjected to rigorous quality testing to ensure the reliability, quality and durability. It has also launched the moneo IoT platform to provide digital sensors, distributed modules and system solutions for predictive maintenance, fault diagnosis and energy management of users' equipment.

Group photo at ifm

Group photo at ifm

This is the 36th international delegation organized by e-works since2014. Through this visit, all the members of the delegation benefited a lot. The company strategy, product positioning, marketing, manufacturing technologies, company operation and talent training, there were many aspects worth learning from, they said.

At present, China is making every effort to promote new industrialization and the new quality productivity. At the same time, many Chinese manufacturing leaders are or trying to expand business to overseas market. At this critical stage, we need to broaden our horizon and learn from the successful experience of international excellent manufacturing enterprises. e-works has rich experience in organizing international intelligent manufacturing delegations, which also provides an effective way for China's manufacturing transformation and upgrading.

The delegation before the Paris City Hall

The delegation before the Paris City HallThe first stop was the CLAAS Tractor Le Mans factory. CLAAS is a world-renowned manufacturer of agricultural machinery and agricultural vehicles. Founded in 1913, CLAAS expanded its business into 150 countries, with factories in 19 countries, including one in Shandong. In recent years, the Le Mans factory has been greatly renovated in order to meet the very complex product configuration needs from the agricultural machinery market.

In the workshop, the delegation watched the processes of power transmission system assembly, cab assembly, final assembly, painting and final check. Le Mans factory produces five different series of tractors and is actively promoting intelligent logistics and automation. CLAAS has made full use of Dassault Systemes' digital solution and factory simulation platform. The introduction of AGVs also made the production process more flexible.

Group photo at CLAAS

Group photo at CLAASThe second stop was the headquarters of Schneider Electric, a global leader in energy efficiency management. As one of the world's leading suppliers of energy management and industrial automation solutions, Schneider Electric provides global enterprises with digital transformation solutions in plant operation optimization, equipment management, and industrial control and safety. The IoT-based EcoStruxure platform provides customers with safe, reliable, efficient, sustainable and interconnected energy management solutions.

Ms. Isabelle Zhang, Director of Business Development at Schneider Electric, and Mr. Jean-Baptiste Fischer, Schneider Industrial Digital Transformation Director, warmly received the delegation at the Innovation Hub and introduced the development history and corporate culture, sustainable development, and typical cases of helping industrial enterprises in realizing intelligent manufacturing. They also shared the of construction of Schneider Electric lighthouse factory as well as the digital transformation services provided by Schneider Electric.

Group photo at Schneider Electric

Group photo at Schneider ElectricThe third stop is the global industrial software giant Dassault Systemes. Mr. Pascal Daloz, CEO of Dassault Systemes, Mr. Ying Zhang, President of Greater China, and other senior executives warmly received the delegation.

Founded in 1981, Dassault Systemes is the world's leading provider of 3D design software, 3D Digital Mock-Up and product lifecycle management (PLM) solutions. For more than 40 years, Dassault Systemes has empowered businesses with its 3DEXPERIENCE platform and virtual twin technology and formed a rich portfolio that enables innovation throughout the entire product lifecycle.

Dr. Pei Huang (right) with Mr. Pascal Daloz (middle) and Mr. Ying Zhang (left)

Dr. Pei Huang (right) with Mr. Pascal Daloz (middle) and Mr. Ying Zhang (left)The fourth stop is the Autostadt and the Volkswagen Wolfsburg plant. Autostadt is the world's first and one of the largest automotive theme parks and service centers. The delegation learned about the history of the automobile and the development of the Volkswagen Group and its various brands, and felt the Volkswagen culture behind the hard steel shell and the mechanical structure. With more than 20 kilometers of automated assembly line and over 6,000 robots, Volkswagen Wolfsburg plant can realize mixed line production of different models of different brands. Here every 16 seconds a car rolls off the line, and the annual output amounts to about 1 million.

Volkswagen Wolfsburg plant

Volkswagen Wolfsburg plantThe fifth stop, the delegation came to one of the world's most influential industrial fairs, Hannover Messe 2024. The members stopped and explored at different stands to get a deep understanding of the latest trends and cutting-edge technologies in industrial development. With the theme of "Energizing a Sustainable Industry", this year the fair focuses on Industry 4.0, artificial intelligence, 5G, electrical engineering, mechanical engineering, energy supply and other fields, attracting more than 4,000 exhibitors from more than 60 countries and regions. This is also e-works' 10th visit to Hannover Messe since 2014.

In the performance testing laboratory, Thomas demonstrated many test projects such as durability test, current cycle test, temperature rise test, flame retardant test, overcurrent test, vibration test, which not only ensure the product quality and performance, but also reflects WAGO's responsible attitude towards the user.

Group photo at WAGO

Group photo at WAGOThe seventh stop was Phoenix Contact, a hidden champion of global electrical manufacturing. By implementing the strategy of "Empowering the All Electric Society", Phoenix Contact is now leveraging their products, digital technologies and solutions to improve the efficiency of production, storage, transmission and use of green energy, enabling the sustainable development of society. The delegation visited the All Electric Society Park, experienced various scenarios of photovoltaic, wind power, heat exchange and electric vehicles, and learned the implementation plan of intelligent control of the power grid. Through augmented reality technology, Phoenix Contact visualized the energy conversion process and made it available for interactive experiences, giving members a deeper understanding of green, energy saving and sustainable development.

Group photo at Phoenix Contact

Group photo at Phoenix ContactThe eighth stop is Schunk, a global leader in toolholding and workholding, gripping technology and automation technology. Mr. Sebastian Höpfl, Executive Vice President of Schunk hosted the delegation. Founded in 1945 by Friedrich Schunk as a small mechanical workshop, Schunk has now evolved into an international technology company with around 3,700 employees in more than 50 countries. Their products have been widely used in a wide range of industries including automotive, electronics, life sciences, aerospace and logistics. The delegation watched the flexible automated assembly lines in the assembly workshop and various grasping technology applications in the Colab, and had in-depth exchanges with Schunk senior executives.

Group photo at Schunk

Group photo at SchunkThe ninth stop is SICK, a world-renowned provider of industrial sensor solutions, where Mr. Markus Scaglioso, Senior Vice President, received the delegation and introduced the development of SICK. After 78 years of continuous innovation and development, SICK has become a very influential smart sensor solution provider worldwide in the field of factory automation, logistics automation and process automation with products widely applied in safety and protection, measurement, positioning, monitoring, identification, and detection. Experts from SICK introduced applications of sensors in flexible automation production line, and the application scenarios and cases of AI-based intelligent sensor, demonstrated the different outdoor sensors in the field, as well as different cases leveraging augmented reality technology.

Group photo at SICK

Group photo at SICKThe final stop was ifm, a hidden champion of electronic sensor industry. Founded in 1969, ifm is one of the leading manufacturers of electronic sensors, providing a wide range of intelligent sensors, distributed modules, controllers, software and system solutions to users with quality services to help them realize intelligent manufacturing and digital transformation. At the ifm R&D and production site in Tettnang, Mr. Frank Watzlawik, ifm Technical Officer Human Resources, once again warmly received the delegation. ifm attaches great importance to product quality and offers a five-year warranty, which is far higher than the industry standard. At ifm, every sensor is subjected to rigorous quality testing to ensure the reliability, quality and durability. It has also launched the moneo IoT platform to provide digital sensors, distributed modules and system solutions for predictive maintenance, fault diagnosis and energy management of users' equipment.

Group photo at ifm

Group photo at ifmThis is the 36th international delegation organized by e-works since2014. Through this visit, all the members of the delegation benefited a lot. The company strategy, product positioning, marketing, manufacturing technologies, company operation and talent training, there were many aspects worth learning from, they said.

At present, China is making every effort to promote new industrialization and the new quality productivity. At the same time, many Chinese manufacturing leaders are or trying to expand business to overseas market. At this critical stage, we need to broaden our horizon and learn from the successful experience of international excellent manufacturing enterprises. e-works has rich experience in organizing international intelligent manufacturing delegations, which also provides an effective way for China's manufacturing transformation and upgrading.