The 10th session of 2024 ICIM lecture series focusing on new quality productive forces

On September 8, 2024, the "Win-win Cooperation: Intelligent Manufacturing in a Global Vision" online lectures series hosted by the International Coalition of Intelligent Manufacturing (ICIM) came to a successful end. This lecture had Jianlei Li, Director of Solution Development and Operation, Hexagon Intelligent Manufacturing Research Institute, and Wenchao Sun, Discrete Manufacturing MOM Expert, Beijing-Fanuc Mechatronics Co., Ltd. as special guests. They brought a wonderful and informative webinar for experts, scholars, enterprise representatives, and industry lovers in the field of intelligent manufacturing. The webinar gained wide attention and attracted over 2,000 views.

Figure 1 Jianlei Li, Director of Solution Development and Operation, Hexagon Intelligent Manufacturing Research Institute

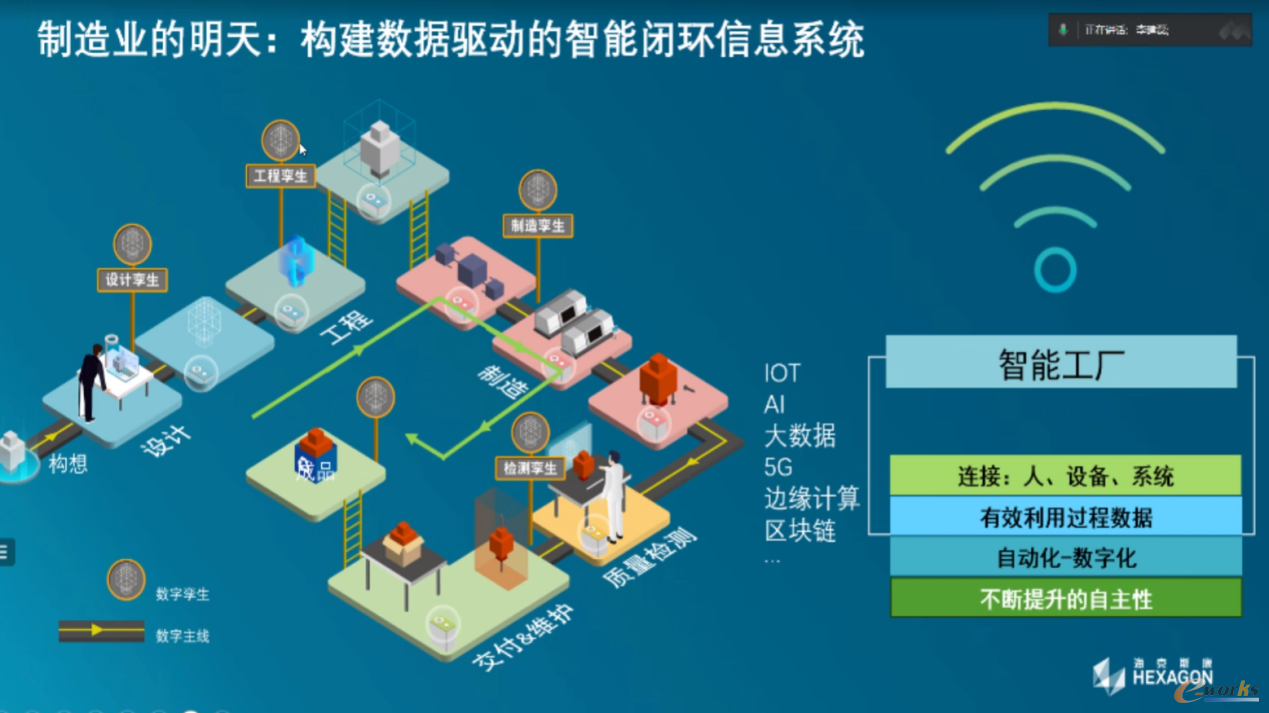

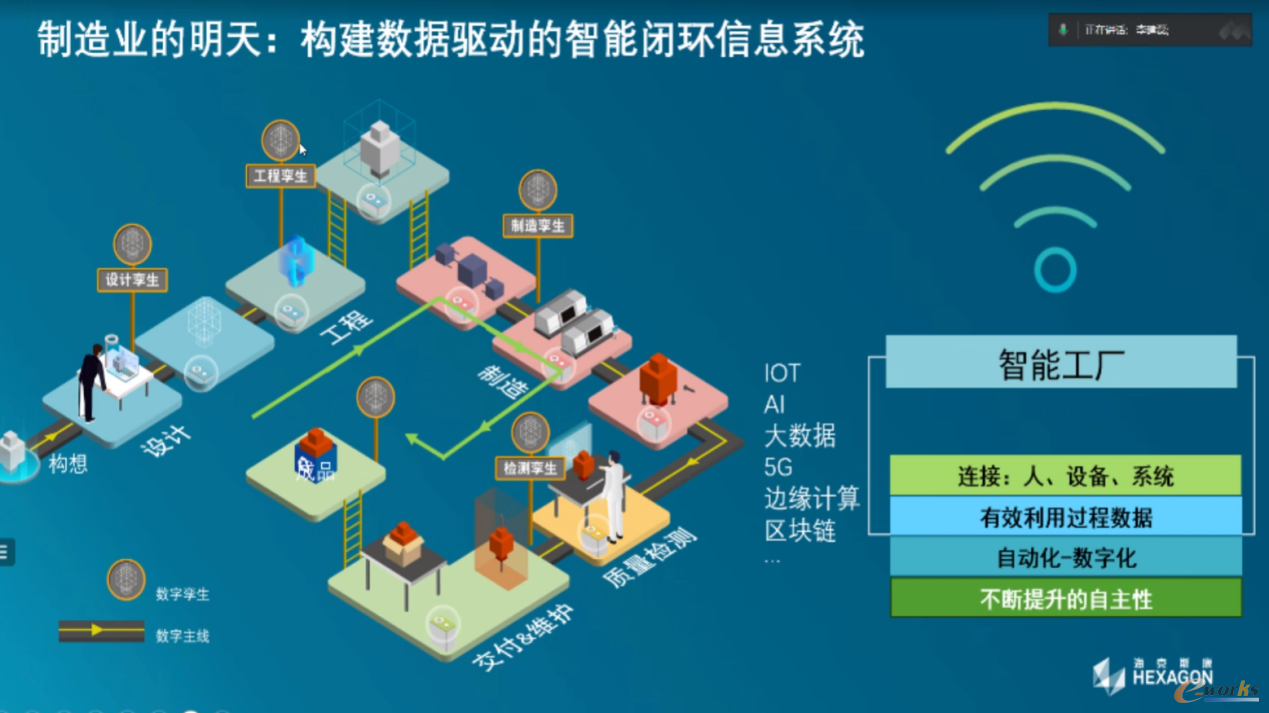

Jianlei Li shared a speech on "The future of manufacturing from the perspective of new quality productivity: from data-driven approach to intelligent manufacturing". Based on Hexagon's experience in information technology, he explained how data can drive intelligent manufacturing across the full lifecycle of product. He said that manufacturing of the future will need to build a data-driven intelligent closed-loop system which enables a full data chain connecting data across all processes from design to operation and maintenance, so as to build an intelligent factory. This requires a close connection of people, machines, materials, methods, and the environment as well as technologies like AI, 5G, and big data to improve the automation of the supply chain and autonomy of the system.

Figure 2 Building a data-driven intelligent closed-loop information system

Mr. Li believes that quality-based intelligent manufacturing is the core of digital transformation. The key to build an intelligent factory is data collection and connectivity, including to connect the digital world with the physical world. This covers data from research and development, supply chain, production, testing, and maintenance. A quality management platform with data collection, analysis, and decision-making can realize the overall solution of intelligent factory.

Figure 3 Wenchao Sun, Discrete Manufacturing MOM Expert, Beijing-Fanuc Mechatronics Co., Ltd.

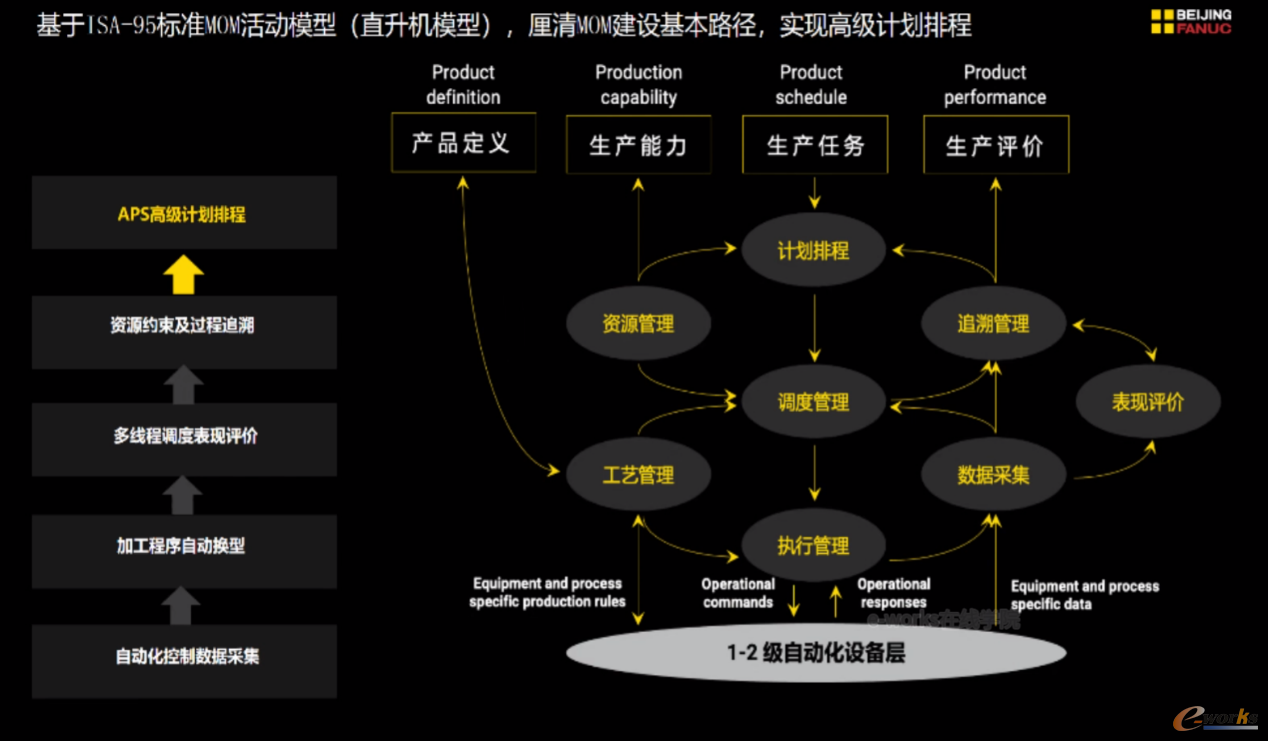

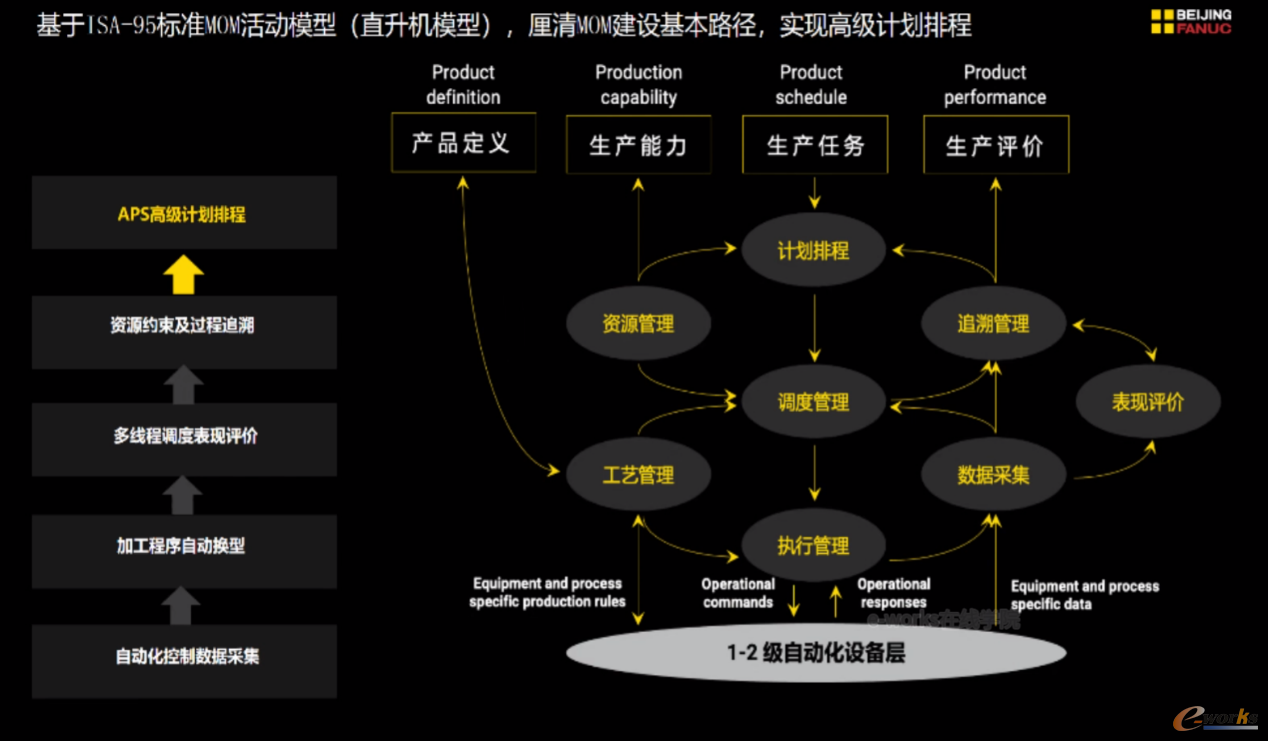

Focusing on the MOM system, Wenchao Sun gave a talk of "Centered around MOM, driving new engines for intelligent manufacturing". He pointed out that the building of a MOM system should be taken step by step, starting from collecting data automatically at the bottom, then move from automatic shift of machining process, efficient scheduling of multiple threads and performance evaluation to resource optimization and full traceability, finally to the smart management with advanced planning and scheduling. Enterprises need to have a deep look based on their strategy, the maturity level, the key problems, and then design a tailored implementation plan, and estimate the ROI, making sure the MOM system both keeping up with the industry trend and also suiting the real situation and of the enterprise.

Figure 4 The basic steps of building a MOM system

Mr. Sun said that new productive forces are accelerators for digital transformation. The goal is to increase total factor productivity a lot, among which new technologies play a very important role. MOM drives digital transformation and smart factory through lean methods. By leveraging new technologies to make system respond more quickly, cut down unproductive work, reduce time for preparation and waiting, it improves collaboration efficiency and realize total quality cost management. For example, to optimize production schedule by using IoT data, to improve error proof rate and production reporting efficiency by transparent manufacturing execution and automatic reporting system, to find production problems in real time and reduce waste through quality traceability system.

The lecture was hosted by Dr. Pei Huang, Deputy Secretary-General of ICIM and CEO of e-works. Ms. Zhongyang Hu of e-works Research was specially invited to have discussions with the guests and answered questions that audience concerns: “What’s the relationship between quality inspection, quality management system, and digital quality management?” “How can we improve machining precision through precise measurement method?” “What are the difficulties in implementing MES and MOM in discrete manufacturing industry?” “What are the application scenarios of generative AI?”

With the ending of the tenth lecture, the ICIM lecture series "Win-win Cooperation: Intelligent Manufacturing in a Global Vision" has also been marked with a success. But this doesn't mean a stop. Instead, it's a new start. We will keep working together with global intelligent manufacturing experts, scholars, and enterprises to push forward the innovation and development of intelligent manufacturing technology and build a more intelligent, green, and sustainable manufacturing of the future.

Figure 1 Jianlei Li, Director of Solution Development and Operation, Hexagon Intelligent Manufacturing Research Institute

Jianlei Li shared a speech on "The future of manufacturing from the perspective of new quality productivity: from data-driven approach to intelligent manufacturing". Based on Hexagon's experience in information technology, he explained how data can drive intelligent manufacturing across the full lifecycle of product. He said that manufacturing of the future will need to build a data-driven intelligent closed-loop system which enables a full data chain connecting data across all processes from design to operation and maintenance, so as to build an intelligent factory. This requires a close connection of people, machines, materials, methods, and the environment as well as technologies like AI, 5G, and big data to improve the automation of the supply chain and autonomy of the system.

Figure 2 Building a data-driven intelligent closed-loop information system

Mr. Li believes that quality-based intelligent manufacturing is the core of digital transformation. The key to build an intelligent factory is data collection and connectivity, including to connect the digital world with the physical world. This covers data from research and development, supply chain, production, testing, and maintenance. A quality management platform with data collection, analysis, and decision-making can realize the overall solution of intelligent factory.

Figure 3 Wenchao Sun, Discrete Manufacturing MOM Expert, Beijing-Fanuc Mechatronics Co., Ltd.

Focusing on the MOM system, Wenchao Sun gave a talk of "Centered around MOM, driving new engines for intelligent manufacturing". He pointed out that the building of a MOM system should be taken step by step, starting from collecting data automatically at the bottom, then move from automatic shift of machining process, efficient scheduling of multiple threads and performance evaluation to resource optimization and full traceability, finally to the smart management with advanced planning and scheduling. Enterprises need to have a deep look based on their strategy, the maturity level, the key problems, and then design a tailored implementation plan, and estimate the ROI, making sure the MOM system both keeping up with the industry trend and also suiting the real situation and of the enterprise.

Figure 4 The basic steps of building a MOM system

Mr. Sun said that new productive forces are accelerators for digital transformation. The goal is to increase total factor productivity a lot, among which new technologies play a very important role. MOM drives digital transformation and smart factory through lean methods. By leveraging new technologies to make system respond more quickly, cut down unproductive work, reduce time for preparation and waiting, it improves collaboration efficiency and realize total quality cost management. For example, to optimize production schedule by using IoT data, to improve error proof rate and production reporting efficiency by transparent manufacturing execution and automatic reporting system, to find production problems in real time and reduce waste through quality traceability system.

The lecture was hosted by Dr. Pei Huang, Deputy Secretary-General of ICIM and CEO of e-works. Ms. Zhongyang Hu of e-works Research was specially invited to have discussions with the guests and answered questions that audience concerns: “What’s the relationship between quality inspection, quality management system, and digital quality management?” “How can we improve machining precision through precise measurement method?” “What are the difficulties in implementing MES and MOM in discrete manufacturing industry?” “What are the application scenarios of generative AI?”

With the ending of the tenth lecture, the ICIM lecture series "Win-win Cooperation: Intelligent Manufacturing in a Global Vision" has also been marked with a success. But this doesn't mean a stop. Instead, it's a new start. We will keep working together with global intelligent manufacturing experts, scholars, and enterprises to push forward the innovation and development of intelligent manufacturing technology and build a more intelligent, green, and sustainable manufacturing of the future.