The 2nd session of 2024 ICIM lecture series focusing on recent developments in digital manufacturing

In the lecture, Professor Kusiak presented the latest developments and practices in digital manufacturing over the past decade, new concepts, and the latest developments and application trends of artificial intelligence.

On July 14, 2024, the International Coalition of Intelligent Manufacturing (ICIM) successfully held the second session of the "Win-win Cooperation: Intelligent Manufacturing in a Global Vision" online lecture series. The lecturer of the lecture "Recent Developments in Digital Manufacturing" is Professor Andrew Kusiak of the University of Iowa. His wonderful lecture has gained wide attention and attracted over 5,000 views.

Professor Andrew Kusiak

In the lecture, Professor Kusiak presented the latest developments and practices in digital manufacturing over the past decade, including ten different scenarios of future intelligent manufacturing, new concepts such as cloud manufacturing and universal manufacturing, and the latest developments and application trends of artificial intelligence. He stated that the ongoing transformation of manufacturing and service industry offers an opportunity to rethink the design of future enterprises. Ten years ago, manufacturing became increasingly dependent on data. There were increased need of modeling, optimization, and simulation. Growing instances where a material, a process, and a product are developed simultaneously.

In the future, the growing volume and flow rate of data across an enterprise (e.g., machine to machine) will naturally lead to a greater horizontal connectivity and interoperability. Sharing manufacturing and transportation resources across manufacturing chains will become a common practice. Diagnosis and prediction of equipment faults will become a routine activity followed by autonomous repair. Meanwhile, cybersecurity and safety issues will still remain a challenge.

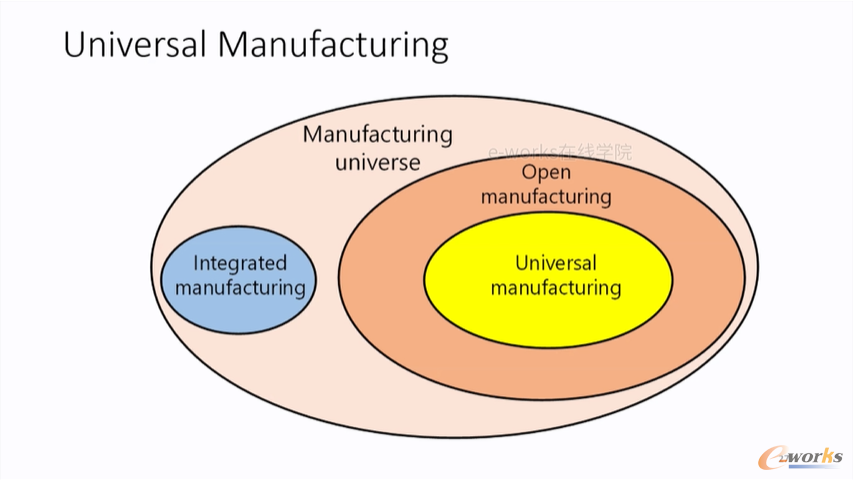

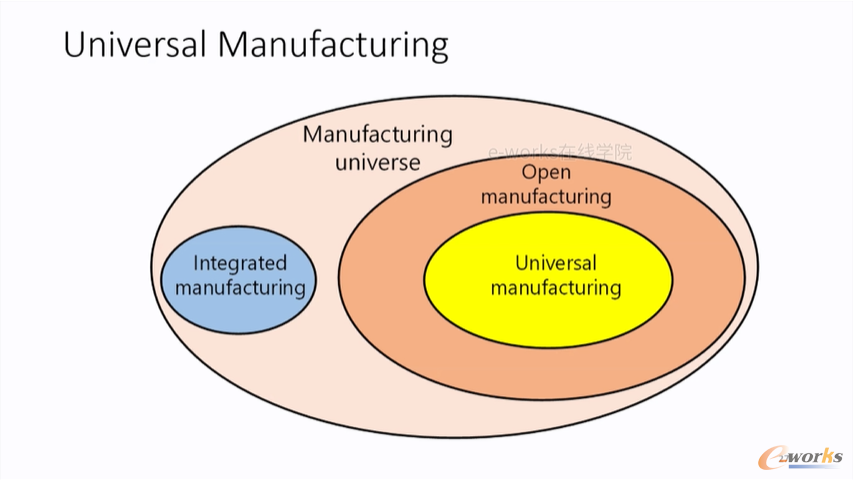

Manufacturing is moving in two different directions: integration and openness. Professor Kusiak noted that from a system perspective, the integrated manufacturing is driven by new material, new process, and new products. One typical representative of this architecture is the "Hidden Champions". According to Forbes that about 2,700 hidden champion companies worldwide are possessing numerous core technologies. On the other hand, the open manufacturing architecture is achieved through globally distributed production facilities. The product-manufacturing relationship is many-to-many, where different products can be produced in multiple manufacturing facilities. In this architecture, manufacturing models in the cloud enable the greater resource utilization, configurability, increased resilience, and small business friendly. Professor Kusiak introduced that as a new type of open manufacturing, universal manufacturing is based on the models of distributed manufacturing facilities, representing the most developed and digitized subset of open manufacturing.

Universal Manufacturing

In terms of the application of AI in digital manufacturing, Professor Kusiak stated that predictive models can be applied to multiple processes in manufacturing, including condition monitoring, fault prediction, process control, quality prediction, product demand prediction, and decision making. Generative AI can also be applied to these areas and can help solve deeper problems. Although the scope of application is broad, the modeling process has significant challenges, such as model complexity, model interpretability, and model reuse.

Looking forward to the future, Professor Kusiak concluded that manufacturing will naturally become more open and resilient; as extreme manufacturing emerges, universal manufacturing may become a dominant form of production systems; on the other hand, interests in model-based system engineering driven by digital manufacturing applications will reemerge, and artificial intelligence will shape key developments.

In the Q&A session, Professor Kusiak answered questions in detail around the application of digital twin platforms, the potential of generative AI, the concept of cloud manufacturing, and the future of open manufacturing. Professor Kusiak's succinct and insightful lecture aroused the audience's learning enthusiasm, and they expressed their thanks for his sharing.

The lecture was hosted by Dr. Pei Huang, Deputy Secretary-General of ICIM and CEO of e-works. It is worth mentioning that Professor Peihua Gu, a Fellow of the Canadian Academy of Engineering, also participated in the discussion.

The live broadcast concluded in a warm atmosphere, receiving highly praise from the audience. As the second lecture of ICIM's " Win-win Cooperation: Intelligent Manufacturing in a Global Vision" series, it built on the success of the previous lecture and deepened the industrial community's understanding and appreciation of the development of digital manufacturing. It also provided new directions for future development and left the audience with a wealth of insights.

Professor Andrew Kusiak

In the lecture, Professor Kusiak presented the latest developments and practices in digital manufacturing over the past decade, including ten different scenarios of future intelligent manufacturing, new concepts such as cloud manufacturing and universal manufacturing, and the latest developments and application trends of artificial intelligence. He stated that the ongoing transformation of manufacturing and service industry offers an opportunity to rethink the design of future enterprises. Ten years ago, manufacturing became increasingly dependent on data. There were increased need of modeling, optimization, and simulation. Growing instances where a material, a process, and a product are developed simultaneously.

In the future, the growing volume and flow rate of data across an enterprise (e.g., machine to machine) will naturally lead to a greater horizontal connectivity and interoperability. Sharing manufacturing and transportation resources across manufacturing chains will become a common practice. Diagnosis and prediction of equipment faults will become a routine activity followed by autonomous repair. Meanwhile, cybersecurity and safety issues will still remain a challenge.

Manufacturing is moving in two different directions: integration and openness. Professor Kusiak noted that from a system perspective, the integrated manufacturing is driven by new material, new process, and new products. One typical representative of this architecture is the "Hidden Champions". According to Forbes that about 2,700 hidden champion companies worldwide are possessing numerous core technologies. On the other hand, the open manufacturing architecture is achieved through globally distributed production facilities. The product-manufacturing relationship is many-to-many, where different products can be produced in multiple manufacturing facilities. In this architecture, manufacturing models in the cloud enable the greater resource utilization, configurability, increased resilience, and small business friendly. Professor Kusiak introduced that as a new type of open manufacturing, universal manufacturing is based on the models of distributed manufacturing facilities, representing the most developed and digitized subset of open manufacturing.

Universal Manufacturing

In terms of the application of AI in digital manufacturing, Professor Kusiak stated that predictive models can be applied to multiple processes in manufacturing, including condition monitoring, fault prediction, process control, quality prediction, product demand prediction, and decision making. Generative AI can also be applied to these areas and can help solve deeper problems. Although the scope of application is broad, the modeling process has significant challenges, such as model complexity, model interpretability, and model reuse.

Looking forward to the future, Professor Kusiak concluded that manufacturing will naturally become more open and resilient; as extreme manufacturing emerges, universal manufacturing may become a dominant form of production systems; on the other hand, interests in model-based system engineering driven by digital manufacturing applications will reemerge, and artificial intelligence will shape key developments.

In the Q&A session, Professor Kusiak answered questions in detail around the application of digital twin platforms, the potential of generative AI, the concept of cloud manufacturing, and the future of open manufacturing. Professor Kusiak's succinct and insightful lecture aroused the audience's learning enthusiasm, and they expressed their thanks for his sharing.

The lecture was hosted by Dr. Pei Huang, Deputy Secretary-General of ICIM and CEO of e-works. It is worth mentioning that Professor Peihua Gu, a Fellow of the Canadian Academy of Engineering, also participated in the discussion.

The live broadcast concluded in a warm atmosphere, receiving highly praise from the audience. As the second lecture of ICIM's " Win-win Cooperation: Intelligent Manufacturing in a Global Vision" series, it built on the success of the previous lecture and deepened the industrial community's understanding and appreciation of the development of digital manufacturing. It also provided new directions for future development and left the audience with a wealth of insights.