EPLAN: How to lead the electrical engineering in the new era?

--Interview with Mr. Haluk Menderes, Global Managing Director of EPLAN

In the new era of digital transformation of global manufacturing industry, as a leading global provider of electrical engineering software, what are EPLAN's key competitive advantages? What new products and solutions does it offer? And how has the growth been for both the global and Chinese markets? With these questions, Dr. Pei Huang, Editor-in-Chief of e-works, interviewed Mr. Haluk Menderes, Global Managing Director of EPLAN in Shanghai in July.

Mr. Haluk Menderes, Global Managing Director of EPLAN

1. The growth of EPLAN globally and in China

As a leading global supplier of electrical engineering software, EPLAN has over 65,000 customers worldwide and has been committed to providing customers with innovative software and solutions in the fields of electrical, automation and mechatronics engineering. Founded in 1984, EPLAN is a subsidiary of the family-owned Friedhelm Loh Group and a sister company of RITTAL. Friedhelm Loh Group has 12 production sites and 95 subsidiaries worldwide, with 12,000 employees and revenues of approximately €3 billion in 2022. Currently, EPLAN has more than 1,500 employees, including 500 developers globally and over 100 employees in China.

During the three years of COVID-19, due to supply chain disruptions and difficulties in recruiting enough workers, an increasing number of manufacturing companies have actively built flexible automated production lines to achieve reduced manpower or even unmanned production. Responding quickly to the market needs with its efficient engineering platform, EPLAN has experienced a rapid growth. “During COVID-19, many companies started investing more in automation and this helped us to grow in every country. In Asia & Pacific, we are growing with double digit. Our Chinese market is growing excellently with double digit in every part of China and has become the second biggest country in EPLAN,” said Mr. Haluk.

According to Haluk, the vision of Industry 4.0 is “becoming a reality” in numerous exceptional enterprises worldwide, and the utilization of artificial intelligence in smart factories is on the rise. Nowadays, the electrification of the world, along with the increasing adoption of renewable energy and accelerated internationalization among industry leaders, has created significant opportunities for the globalization of EPLAN.

When talking about the automotive industry, Haluk was amazed by China's remarkable innovation capabilities and advancements in electric vehicles. “Germany has been leading over the decades in automotive industry, and may be still in some parts, but as you see in the electrical verticals sector, China is growing and producing with great innovation. This is what’s happening. But it will also require that the tools used or to be used need to support this innovation. When we started business in China, most of customers were European companies, but now mostly Chinese. So we strongly believe that China will be our biggest market,” said Haluk.

Although currently, China places great importance on the localization of industrial software and actively supports domestic industrial software companies, Haluk shows no concerns about their growth in China. “I think Germany and China are really working collaboratively with each other. And we are localizing a lot of things here too, developing more and more localized parts to the EPLAN. So it will be, I think, a good business both for China industry and EPLAN,” said Haluk.

2. From electrical design software to a total solution provider

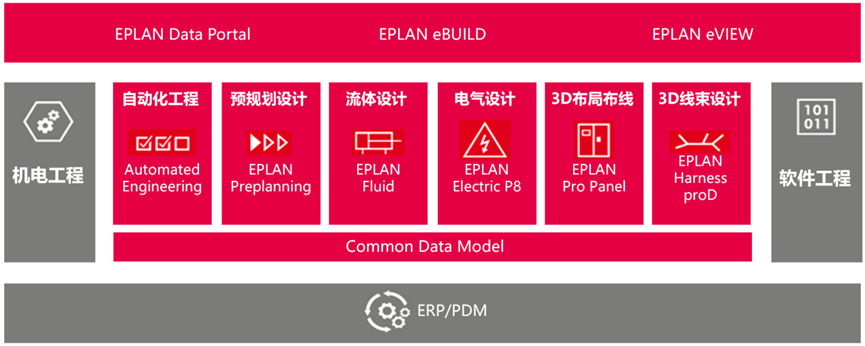

Haluk emphasized that EPLAN not only offers electrical CAD software, but also provides an integrated total solution and platform for electrical engineering to assist manufacturing companies throughout the entire product development process, from generating ideas for new product design to automation engineering, pre-planning, electrical engineering, fluid (pneumatic, hydraulic, cooling and lubrication) engineering, as well as 3D wiring and harness design. The platform incorporates the EPLAN Data Portal, an electrical components database that contains massive data on 1 million components from over 340 suppliers. EPLAN focuses on integrating both the upstream and downstream processes of electrical design while ensuring seamless data integration, including integration with mechanical engineering and software engineering, and mainstream PDM and ERP systems. Furthermore, the efficiency from design to manufacturing has been greatly improved with the aid of emerging technologies such as AI and AR.

EPLAN eMANAGE solution enables collaboration between the ecosystem of industrial automation. “Companies can share data, exchange data and always work together on the same data with subsidiaries, suppliers, and partners within the ecosystem,” said Haluk. EPLAN also offers a service and maintenance solution called “eVIEW”, which allows technical people or technicians to collaborate and view up-to-date versions of electrical engineering documentation on tablets or smartphones.

EPLAN is actively promoting cloud applications and subscription models. Haluk mentioned that by acquiring a cloud development company, they are currently working on several cloud-based solutions to extend EPLAN's portfolio and enable collaborative development with partners while ensuring secure data sharing within authorized permissions.

EPLAN has also released Smart Mounting and Smart Wiring solutions. The Smart Mounting system is simple with clear mounting instructions. EPLAN Pro Panel generates a digital twin of the enclosure and uses AR technology to visualize operating steps, which can be easily mastered by employees without professional experience. This helps to address the problem of skilled labor shortage in cabinet manufacturing. Smart Wiring can assist workers on the shop floor in complete the wiring tasks.

Additionally, EPLAN provides API tools that users can apply to extend the system’s functionality. The API will be still the same even after the upgrade. EPLAN also offers a professional team to help customers develop APIs.

The main products of EPLAN cloud module include Data Portal, which provides high-quality engineering data; eBUILD, which can automatically generate schematics; eMANAGE, used for collaborative design in the cloud; and eSTOCK, a central database of components in the cloud. They constitute a whole set of cloud solutions that complete the data flow to achieve digitalization and intelligence in product design. EPLAN Data Portal includes product business data, functionality data, schematic design models, layout models, 3D layout models, 3D CNC machining data, 3D wiring data, etc., which can be applied at each stage of engineering design and can solve customers’ data flow problems at all stages. Now EPLAN is actively promoting the localization of more cloud applications in China.

An important trend in the electrical engineering software is “the intelligent engineering driven system which can give advice on how to do the engineering based on data, experience, and artificial intelligence”, according to Haluk. EPLAN has established an AI team and is actively collaborating with AI vendors. It is also working on simulation applications in the field of electrical engineering.

EPLAN's integrated electrical engineering solutions (red part)

EPLAN's integrated electrical engineering solutions (red part)3. Transforming and innovating product and service models

The EPLAN platform offers a range of products, with the most well-known ones being EPLAN Electric P8 for electrical design, EPLAN Fluid for pneumatic and hydraulic automation schematics engineering, and EPLAN Pro Panel for 3D cabinet design. These products are widely recognized as "the good helpers of electrical design automation". In addition, there are other products such as EPLAN Automated Engineering Design for automatic drawing design, EPLAN Preplanning platform for large-scale project production line design. By integrating the entire business process from design to production, these products assist customers in optimizing process, reducing project design time, and saving engineering costs.

EPLAN is actively moving to a subscription model. According to Haluk, since two and a half years ago, all new customers have adopted the subscription model, while 70% of existing customers have converted to subscription. The advantage of the subscription model is that users have the flexibility to adjust the number of users as needed, and they can always use the latest version. “EPLAN has begun to transition to a subscription model in China, and although the situation is much better than expected, the acceptance rate of local Chinese enterprises, especially state-owned enterprises, is not very high”, said Qin Zheng, General Manager of EPLAN Greater China. “Customers will only be willing to renew their subscriptions if we can support their success by providing a full range of services. At present, only subscription is sold in Taiwan; In the mainland market, we expect to stop selling permanent licenses by the end of 2026, except for a few government-sponsored engineering projects.”

4. Deep into industry to enable manufacturing innovation

Electrical engineering is essential for innovation in a variety of manufacturing sectors. EPLAN solutions focus on assisting these industries with automation, particularly in key sectors such as cabinet manufacturing, automotive, equipment manufacturing, energy and power, construction, ship and marine engineering, food and beverage, and metallurgy. Haluk emphasized that EPLAN will effectively support the development of vehicle electrification and facilitate utilization of clean energy as well as automation of building. EPLAN provides a collaborative platform for owners, OEMs/system integrators, module manufacturers, and component suppliers involved in industrial automation projects.

EPLAN has a strong focus on guiding customers in the right direction. According to Haluk, before the software goes live for each new customer, EPLAN guides them to make full preparations, which include providing consulting and professional training services, offering digital templates, and standardizing the process from electrical design to manufacturing. “Once it's standardized, then the future is automation. We can help customers get off to a quick start and get very successful and efficient in a very short way,” said Haluk.

Qin pointed out that EPLAN has helped numerous customers successfully carry out electrical digital transformation and expand the application. “Based on previous successful experiences, we have developed a professional implementation process consisting of 6 steps, which cover the entire business analysis, demand analysis, blueprint design and review, development and implementation, testing and verification, as well as training and promotion. Combined with the advantages of agile development, we can help customers quickly implement electrical digital transformation and upgrade,” said Qin.

EPLAN Industrial automation collaboration platform

EPLAN works closely with its sister company Rittal, complementing and reinforcing each other. Rittal not only produces a variety of control cabinets but also supplies a variety of equipment and tools for cabinet production. Meanwhile, EPLAN software is responsible for electrical engineering design, enabling the 3D digital design and CNC machining of cabinets.

The integrated cabinet design solution by EPLAN and Rittal

The fully integrated solution of EPLAN and Rittal

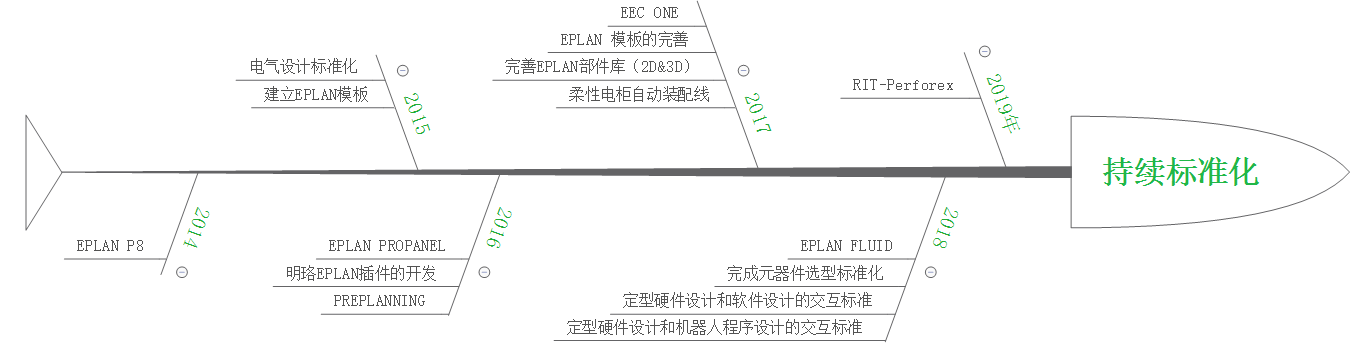

EPLAN has built up a large customer base through long-term commitment to the industry. Most of the world's well-known automotive companies and almost all EV manufacturers are EPLAN’s users. More than 90 out of the Top 200 global equipment manufacturers are users of EPLAN. Qin introduced that EPLAN has an obvious advantage in China's automotive, steel, machinery, and energy and power industries. Most foreign ventures and joint ventures in automotive are EPLAN customers. For local automobile companies such as BYD, Great Wall, Geely, Nio, and CATL (a leading power battery enterprise), they are all typical users of EPLAN. In the steel industry, enterprises like CISDI Group, Capital Engineering & Research Incorporation (CERI), WISDRI Engineering & Research Incorporation (WISDRI), JIGANG, LAIGANG are all using EPLAN software. Leading construction machinery manufacturers like Sany, XCMG, Zoomlion, Sunward and Shantui are using EPLAN. Typical users in the high-voltage industry include Pinggao, China XD Group; while in the medium and low voltage industry, both international giants such as Siemens, ABB, Schneider Electric, Rockwell, Mitsubishi Electric and local enterprises like SOJO Electric and Jinpan Technology are all typical customers. And among the mainstream industrial automation integrators, there are many customers including Guangdong Lyric Robot Automation and Guangzhou MINO Equipment. In 2014, MINO began cooperating with EPLAN to develop unified standards for identification, labels and documents, etc., reducing the original design period of more than 1500 working hours to just 210 working hours, resulting in an efficiency increase of 86%.

MINO’s practice of shortening design cycle by using EPLAN software

5. Improve local service and ecosystem

Since China is too big to rely solely on their own team, EPLAN will expand its network of partners to strengthen local support and services to the customers in China. While EPLAN mainly engages in direct sales in other countries, it uses a hybrid model of direct sales and distribution to expand its coverage through partners in China.

Qin introduced that EPLAN started its partner program three years ago and now there are nearly 80 partners. EPLAN is helping these partners improve their capabilities, as many of them are familiar with software in mechanical engineering, but not so familiar with electrical engineering. EPLAN plans to triple its team in China over the next three years and continue increasing its efforts to help them enhance their professional capabilities

EPLAN attaches great importance to the training of customers and partners, and also cooperates with universities and institutes to train students so they can learn advanced electrical engineering design methods. It has established a professional consulting team that provides customers with electrical engineering consulting services while assisting partners in improving their consulting capabilities. For upstream system integrators, EPLAN focuses on helping them establish industry standards; for midstream OEMs, it concentrates on applying design standards to their equipment; and for downstream component manufacturers, there’s a dedicated Data Portal team at EPLAN that incorporates domestic component manufacturers into its online component database.

Postscript

Last time I met Haluk was at the launch celebration of EPLAN Shanghai in 2018. It was a great pleasure to meet him again. He is very confident in the growth of Chinese market and anticipates the expansion of the Chinese team and its partner ecosystem. With a strong engineering background, he is very interested in exploring and applying emerging digital technologies. Visiting customers and attentively listening to their needs and suggestions is something he truly enjoys, as it allows him to constantly learning from them and improve EPLAN products and services. EPLAN has been devoted to electrical engineering for a long time, establishing an integrated platform along with industry-specific solutions. Looking ahead into the future, the application of EPLAN software will bring significant value for most manufacturing enterprises in China by achieving mechatronics integration and accelerating product innovation.

Dr. Huang Pei (left) and Mr. Haluk Menderes (right)