Bring the Spring of ‘Digital Workshop’

I interviewed Mr. Gilles BATTIER, the C.E.O. and the owner of SPRING technologies, in its’ Beijing office. Mr. Eric LEMAIRE, the general manager of SPRING Technologies Beijing office, also joined the interview.

Mr. Gilles BATTIER, SPRING Technologies C.E.O.

On a morning of autumn 2010, I interviewed Mr. Gilles BATTIER, the C.E.O. and the owner of SPRING technologies, in its’ Beijing office. SPRING is the French acronym for "Industrial automation and research in numeric and graphic imagery company”. SPRING Technologies is a specialized solution provider of digital manufacturing whose headquarter is located in Paris, France. It is very interesting that Mr. Gilles BATTIER visited e-works headquarter in 2005 during his first trip to China, and next to that trip, decided to begin its’ Chinese business in 2008. Mr. Eric LEMAIRE, the general manager of SPRING Technologies Beijing office, also joined the interview.

Pei Huang: Please give me a brief introduction of your company, SPRING Technologies.

Gilles Battier: We focus on manufacturing productivity improvement. SPRING Technologies has more than 26 years’ experiences. The global revenue was 14 million Euros in 2009. We are based in Europe. I first visited China 5 years ago because I identified the incredible potential of the Chinese market. So I decided to invest in China 2 years ago (beginning of 2009) even before the American market. We just set up an office in U.S. (Boston) at beginning of 2010 and already won very sensitive and important deals such as the U.S. Army. In Europe, we are based in Germany, Switzerland and France, and we complete our coverage with our worldwide business partners. We have 150 employees and 90% of them are typical engineers.

Today, the high level of expertise and technology of our Chinese partners and customers will require the highest level of services from Spring Technologies. The Chinese market is also growing very fast and the potential of the industry and the needs in manufacturing will be growing, especially on high end technology application. This is with this objective that, today, Spring Technologies opened in 2008 its local office in Beijing and is until now reinforcing its local team to increase its service level and support in China and bringing the highest level of technical and commercial expertise to our new Chinese collaborators.

Our ‘Digital Workshop’ suite has today more than 1000 worldwide customers in Aeronautics, Aerospace, Defense & Security, Energy, Automotive, Industrial equipments and Services Industries. We also adopted a specific strategy with schools and universities, so we have up to now more than 400 worldwide school and university partnerships. Teachers and students can be trained on our technologies before they come to the work market, this is the reason why we started cooperating with universities in China but not the only reason, we also cooperate with the Chinese most famous Universities (Tsinghua, Beihang, Tianjin) on common R&D projects. At the beginning, more than 20years ago, SPING Technologies developed specific applications for our customers, especially in automotive industry. Now, we also do a lot of consulting, training etc. around CAD/CAM systems. We also implement PLM technologies for SAP, Siemens PLM, PTC, Dassault Systemes, etc. We finally offer CAD training in France.

Pei: Please briefly introduce yourself and SPRING Technologies vision.

Gilles: Before I started this company, I was an engineer. The University I went in France (Ensiame) was the first University in France using CAD/CAM software. I was very excited by these technologies, so I decided to do my studies in this area. I started my professional career in SAINT-GOBAIN which is a big European group for construction and cars’ glasses manufacturing. I worked in SAINT-GOBAIN Competence Center. My job was to visit the group different plants and manufacturing sites to help the managers to implement the use of CAD/CAM technologies. I did this kind of work for several years and thus got to know the automotive industry very well.

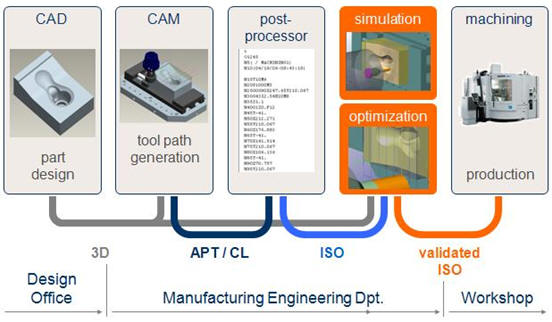

I have been SPRING Technologies C.E.O. since 1993. My mission is to directly work at the heart of the manufacturing industries to improve their competitiveness. With CAD/CAM and NC technologies, we can dramatically improve the productivity of our customers. SPRING Technologies strategy in China is to provide the leading “Digital Workshop” software solution to help customers optimize their manufacturing process, including machining simulation, cutting tool management and capitalization of the corporate know-how. Since the beginning, I am convinced that we need to have a global view of the ‘Product’ from the design department to the workshop. This is with this ‘vision’ that when I bought SRING Technologies in 1993, I decided to reinforce the numerical chain from design to manufacturing along with reinforcing the global knowledge of the workshop. Nowadays, because the product lifecycle is shorter and shorter, and the product manufacturing is more and more complex and expensive, I think that the manufacturing process will be a vital step for a new product to be selected and qualified for commercialization. However, many designers still do not take care about the manufacturing process, and they probably don’t choose the right way and right tools to reduce the production and manufacturing costs. Therefore, several years ago, I decided not only to pay attention on the technologies provided by Dassault or PTC, but also invest time and energy on developing our own software and solutions to continue growing.

The name of our software suite is called ‘Digital Workshop’. There are several reasons for choosing this name. First, we want to be integrated in the numerical chain because we want to work in the middle of all the numerical information including CAD, ERP and MES systems (etc.). Second, we are focusing our work on helping our customers and partners to improve their machine tool productivity.

Our first experience was regarding the post-processing. At the early times, manufacturing enterprises were using the machine tool to directly check the tools paths. We therefore decided to help those manufacturing companies to check the tool path offline and decided to develop NCSIMUL.

Another problem we detected was, sometimes the NC machine wasn’t working or stopped because the tool was broken due to the technical guy didn’t choose the right tool regarding of the machined material and the manufacturing function. We therefore decided to buy a company specialized in cutting conditions, and we integrated this solution in our solution suite (TOOLSIMUL). Step by step, we developed our technologies following this strategy, bringing the PLM solutions from the Design Department to the foot of the Machine Tools. The last solution we developed, for example, is a Tool Management System (TOOLEXPERT). We noticed in the workshop that a NC Machine Tool is stopped because the cutting tool is not ready, so we think of a way how to help our customers to prepare and predict what he needs to manufacture the parts and to know and track at a ‘t’ time, where a cutting tool is, within the whole workshop.

So as you see, we SPRING Technology come from the automotive industry, and concentrate today its activities in aeronautics, energy, power, transportation markets. Where our customers are using very expensive parts whose manufacturing is very complex and risky, we will be supporting its activities.

We are also a PLM (Product Lifecycle Management) service provider because the technology alone doesn’t work. You also need to train the people to implement the technology in their own office.

Pei: Do you also have some PDM functions or you can integrate your software with other PDM system?

Gilles: Our solutions can be integrated with PDM systems, and we extend PDM technology to the workshop. For example, our Tool Management software is able to manage the cutting tools within the workshop. Our customers are equipped with PDM, CAD/CAM, MRP/ERP systems and also DNC system. Our goal is to use Digital Workshop to help our customers prepare the documentation for manufacturing using WIPLINK, simulate the tool path with NCSIMUL, manage the cutting conditions with TOOLSIMUL, and manage the cutting tools with TOOLEXPERT.

Every module can be run alone, but also can be run all together. For example, you can combine NC simulation with the cutting conditions solution when you want to optimize the speed of the cutting tool. Our solutions are scalable to fit the requirements and needs of SMEs and large enterprises to cover the needs for digital manufacturing and integrate with mainstream PDM and CAD/CAM solutions.

Pei: Please briefly introduce your product portfolio and your product strategy.

Gilles: Sure. Our knowledge comes from the post processing. So, we have the capability to simulate all the controllers in the world, the more complex the controllers are, the better it is for us as we have up to know more than 25 years experience in post processing and the unique company in the world to be able to simulate some kind of very complex machines. 10 years ago, we started to simulate 5-axis NC Machines, and we were more than confident that the market would need more and more complex machines for their users to rapidly improve their productivity. We were very excited when we saw the first mill-turn machines coming into the market. Today, every CAM provider is coming with a simulation module, but if you look closely at the capability of the simulation module, it’s far from what NCSIMUL is providing. The more complex the machines are, the better value added will have our solutions compared to CAM simulation. Our solution NCSIMUL can check the ISO code, tool paths, check the collisions and is able to simulate the very complex machines in the world.

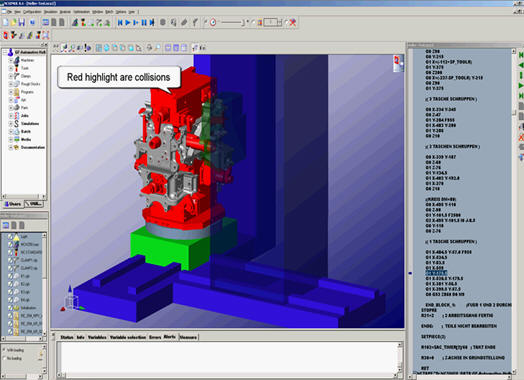

The application of SPRING NC simulation and optimization solution

At the beginning, we developed NCSIMUL on Z Buffer technology. Two years ago, we heavily invested to use new available technology to improve the quality and speed of our NC simulation. We also developed our technology around the kernels of machine works library which is based on 3D modeling and Boolean calculation, so that our simulator became the fastest available on the market and is very easy to use and user friendly. When simulating using Z Buffer technology, if the user wants to zoom and rotate the modeling during the simulation, it will considerably slow down the simulation because of the time taken to recalculate the data. Our customers were asking us not only to simulate the tool paths for normal NC Machine Tools, but also simulate the tool paths for complex machines and very complex parts using a lot of data and calculation capabilities. We therefore used Boolean technology to be more efficient and much faster. We think that it is more than necessary to simulate the 3D models of the NC machines because for some complex machine like mill-turn or turn-mill, the simulation is only useful if the engineer is able to see the machines in 3D, check the tool path, detect collisions or syntax errors etc.

The NCSIMUL interface

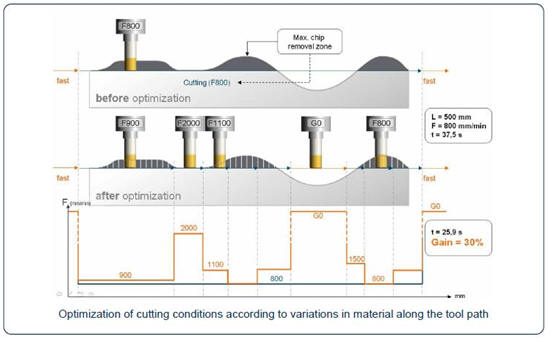

As far as ‘optimization’ is concerned, our software is capable of dealing with 3 levels of optimization. The first level is air cutting optimization. We are able to know when the cutting tool is inside the material or not, then we can help our customers to improve the cutting machining speed when the cutting tool is outside of the material.

For roughing manufacturing operations, our solution can reduce more than 20% of the machining time. Also, we can calculate the volume of material that will be removed, and we have knowledge about the cutting conditions, we can help our customers to choose the right cutting tool for the right type of material to improve the cutting speed. This is the second level of optimization NCSIMUL is able to integrate. Finally, the third level optimization is unique. We can deeply analyze the cutting conditions of the machined material characteristics, we calculate how much volume of material is removed and which kind of the material is used, regarding our 25 years knowledge on the field, we are able to optimize the tool paths of any of our customers.

The last but not the least is SPRING Technologies Tool Management solution: TOOLEXPERT. A lot of CAM systems propose integrated cutting tool libraries, but it is not connected with the existing physical tools in the workshop. Because CAM engineers have the power to choose the tools they want, the number of cutting tools within the workshop is dramatically increasing, because they often use non-standard tools, the cost is also increasing. With TOOLEXPERT, we can give CAM engineers the necessary information directly coming from the workshop: which tool already exists, which tool has already been validated for what kind of material, etc. So, when our customers want to choose a the right cutting tool, they don’t request it from the CAM library, they request it from TOOEXPERT, where they can store the corporate know-how and their experience about the cutting conditions, the materials and lifetimes of the cutting tools. It’s very important that based on the manufacturing requests and constraints, our customers have the ability to choose the best tools for manufacturing.

Tool management solution of SPRING Technologies

The use of TOOLEXPERT is more general, it is able to manage the lifecycle information of all sorts of cutting tools and add the information of the corporate manufacturing experience and know-how.

We are very confident with our technology, so we entered the U.S. market and we won this year a big deal in U.S. army because from the technical point of view, our solution is easier to use, quicker and more powerful.

In the future, we will develop more MES functions because we think that from the planning or workshop management point of view, there is still huge productivity potentials to work on.

Pei: Which factors really attracted SPRING Technologies to enter Chinese market?

Gilles: China has been very aggressive and pro-active on building its own large aircrafts, satellites, shuttles, new generation of motors, etc. We are already giving our best service & support capabilities to these industries. Last year, China has been the largest consumer and the largest producer for NC machine tools. Where there are more and more complex machine tools is where we should develop. Also, more and more western machine tool companies build their production center in China, because of the low cost, and the increasing need of the market, we have to follow our customers and at the same time more than willing to develop Chinese local customers. We then set up our Beijing office to locally support our Chinese customers. As an engineer, I like very much to visit our customer workshops. I’m very proud that our technology can help our Chinese customers to realize their imagination. We have today 6 VARs in China and we are developing more strategic partners to cover the overall Chinese market.

Pei: How about your business growing in Chinese market?

Gilles: China is a big country, and the culture is of course different from Europe, so we have to learn. We hired a local team to join us not only to improve our commercial and technical support capability, but also to improve our R&D capability. I think that the needs of Chinese customers will be very important for us in the future, so we should build an R&D team here, in China. We started a joint R&D project with Tsinghua University to develop 3D modeling for the NURBS (Non-Uniform Rational Basis Spline). We are also cooperating with Beijing University of Aeronautics and Astronautics and Tianjin University. We build a long term vision for the Chinese market. Now, we have already built some references, such as Haier, AVIC, CAST, Messier Dowty etc.

Pei: Please share some development achievements of NC simulation technology.

Gilles: SPRING Technologies is heavily investing and focuses on improving our technology capability on NC simulation. For example, we joined a research program in Europe, which is simulating the vibration and the deformation of the machined parts and cutting tool during the machining. The problems we want to solve are:

1. The vibration of the cutting tool during the machining will impact the surface quality, and sometimes lead to the brake or damage of the cutting tool.

2. When machining the parts with very thin depth, the part will vibrate during the machining process.

3. The removal of material will impact the surface quality if the tool path is not optimized.

So, we developed the algorithm based on FEA to analyze the constraints and pressures of the machining process, visualize the vibration of part and cutting tool, detect the potential problem, and finally optimize the tool path. We are trying to simulate the NC manufacturing even more accurately and we will integrate those achievements into our NCSIMUL product in the near future.

Picture of Pei Huang and Gilles Battier

About Mr. Gilles BATTIER

Gilles BATTIER started his career as a CAD/CAM Consultant within the SAINT-GOBAIN Competence Center. He joined SPRING Technologies in 1988 as sales support engineer and rose quickly to the position of Sales Director, before becoming General Managing Director, and finally Chief Executive Officer in 1994. In this role he has masterminded a series of strategic projects, notably the company’s expansion into the international arena. The first office outside France was opened in Switzerland, followed by Germany, and in 2008 SPRING Technologies launched its Chinese subsidiary. SPRING Technologies just began its USA operation in 2010. Under BATTIER’s leadership the company is proactive in ambitious French and international research programs involving competitiveness clusters like the Paris region branch of System@tic and Arve Industries in the Jura, as well as China’s Tsinghua University.

Editor: Sophie Shi ss@e-works.net.cn