Vero Introduces VISI-Shoes Using VISI-Modeling System

With its greatly increased presence in China following the opening of its Shanghai office and a major increase in its Chinese distribution support network, Vero feels the introduction of VISI-Shoes will be strategically important in China.

World footwear production is currently estimated at 800 billion pairs of shoes manufactured annually with China and Hong Kong alone accounting for around 50% of the total*.

With its greatly increased presence in China following the opening of its Shanghai office and a major increase in its Chinese distribution support network, Vero feels the introduction of VISI-Shoes will be strategically important in China.

“This industry specific product has been developed to meet the enormous demand, particularly in China,” explains Richard Youhill, sales director for Vero International Software.

“It was introduced at the 7th Eastpo International Machine Tool Fair which opened today in Shanghai and which is expected to attract over 80,000 trade buyers, many from the die and mould sector which is closely allied to the shoe industry,” he adds.

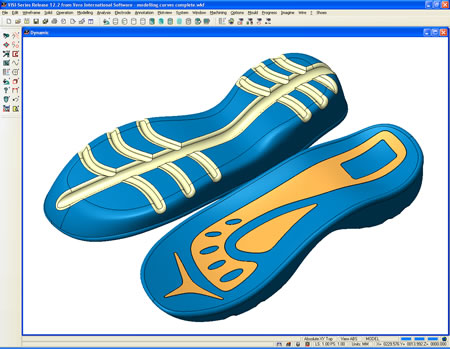

With VISI-Shoes the entire design and manufacturing process is catered for in one, totally coordinated environment. All design stages including the insole, sole, heel and mould tool can be easily and rapidly created and even the shoe last design is accommodated.

The original 2D or 3D data from the shoe designer is imported into one of VISI-Shoes 4 modules – modeling, grading, tool build and machining. A feature that is unique to VISI-Shoes is the automated insole design with the ability to apply a toe spring value that ensures the insole retains it correct shape when removed from the shoe last.

Another unique feature is the ability to grade (size) with a constant heel size, (especially on women’s shoes) providing the option to fix the back of the sole so that multiple shoe sizes can use the same heel.

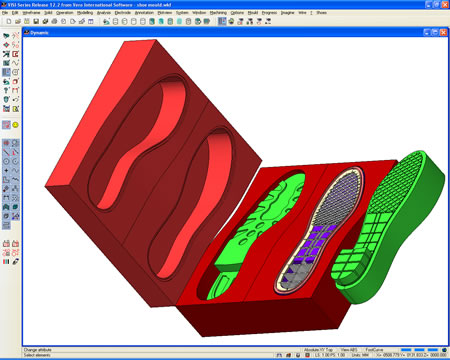

Injection moulds for PVC, EVA, rubber and polyurethane soles are created using VISI-Shoe

The mould tool can be produced automatically from the 3D shoe model providing the ability to create both the core and cavity mould plates and the upper and lower punches.

The Modeling function within VISI-Shoes features solid and surface modeling tools

VISI-Shoes complies with industry standard sizing using Shtih,inch/metric or user defined methods.

“VISI-Shoes is another example of how adaptable the core VISI-Series product is for a wide cross section of manufacturing industries,” adds Richard Youhill.

“We believe its ease of use features coupled with advanced functionality in a number of its modules will ensure it receives an enthusiastic response,” he concludes.

Vero International Software is represented in over 40 countries by more than 80 distributors and, in addition to its extensive dealer network, has its own direct sales operations in the UK, France, Italy, USA, Japan China and Canada.