The 2024 ICIM lecture series concluded successfully

On September 8, 2024, the ICIM public online lecture series "Win-win Cooperation: Intelligent Manufacturing in a Global Vision" was successfully concluded. The total of ten lectures attracted the participation of tens of thousands of professionals around the world to jointly explore the emerging technologies and future trends of intelligent manufacturing, drawing a grand blueprint for the development of the industry.

Figure 1 ""Win-win Cooperation: Intelligent Manufacturing in a Global Vision" lecture series

International scholars discussing the future of intelligent manufacturing

This series of lectures brought together many international intelligent manufacturing experts and industry benchmarks. They had in-depth discussions on the latest progress, technological innovation and future blueprint of intelligent manufacturing. The series covered many popular technologies, such as artificial intelligence, additive manufacturing, digital thread, AI agent, PHM, and MOM as well as leading practices of Industry 4.0 and intelligent manufacturing, and future trends. Each session is full of cutting-edge research and profound insights.

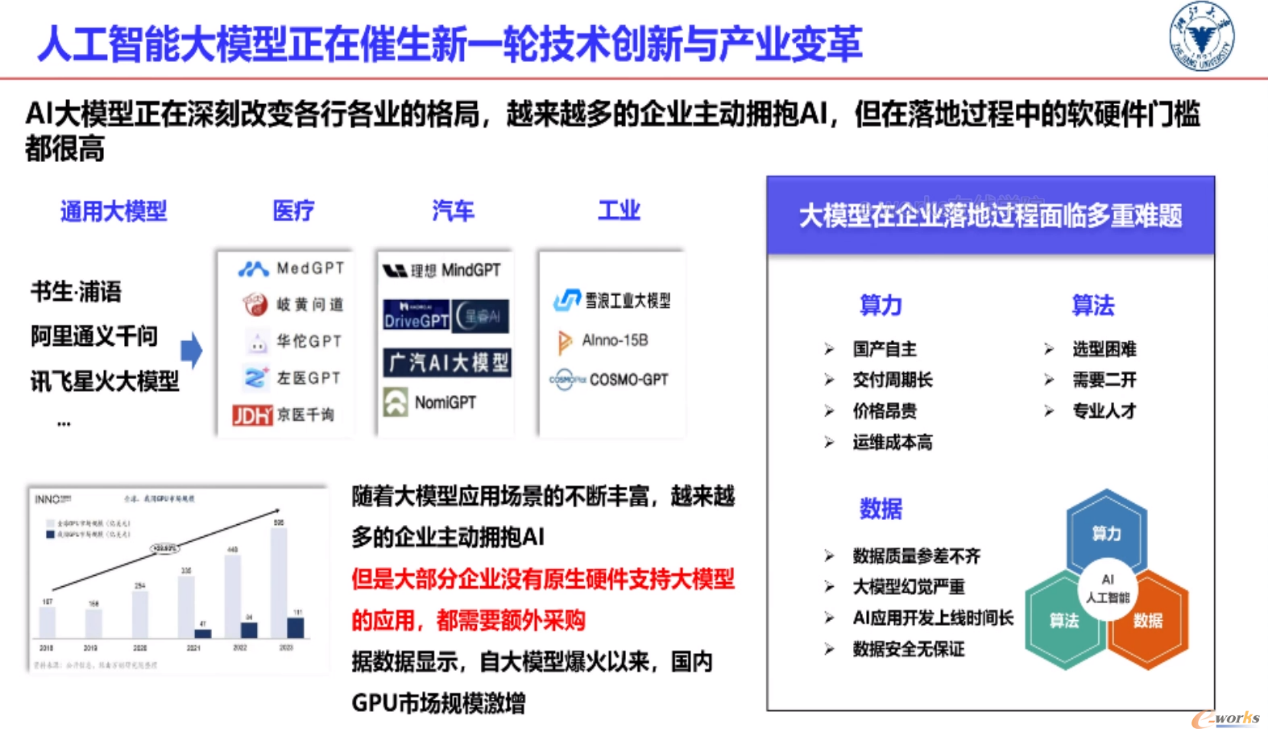

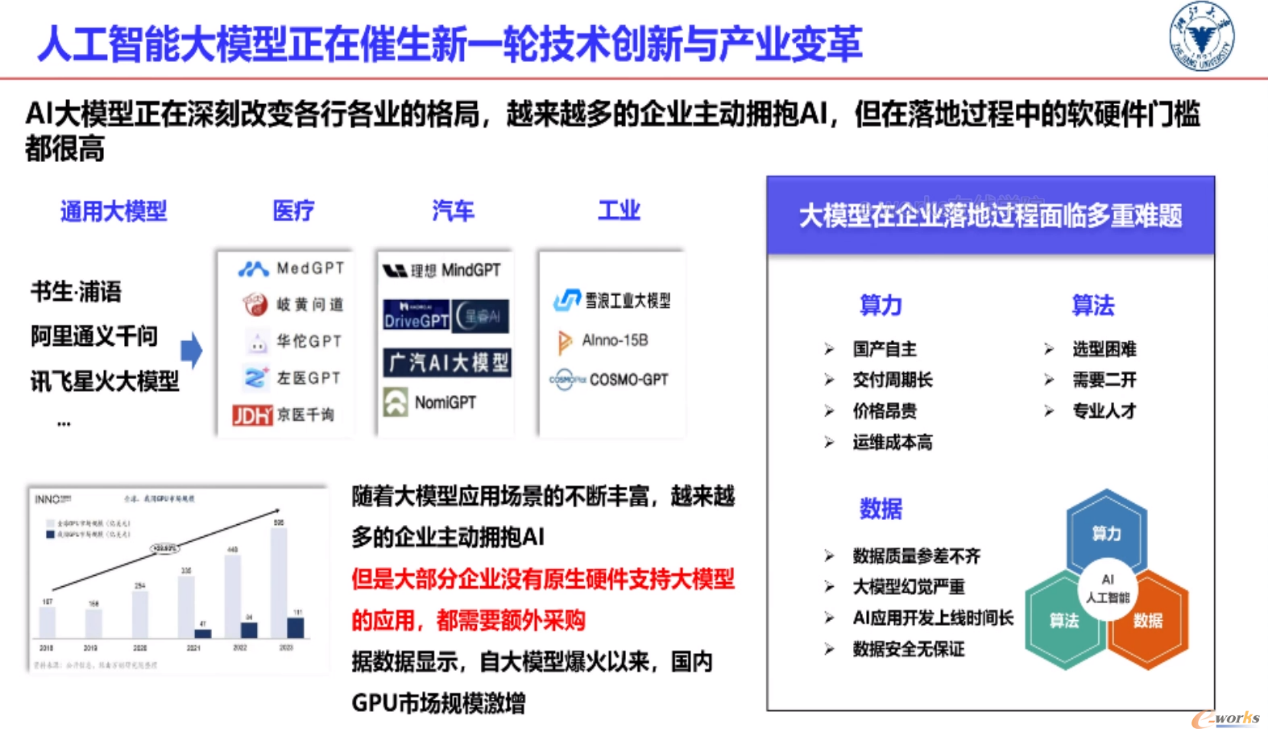

In the lecture "Some Explorations on Digital Transformation of AI-powered Machinery Equipment", Professor Huayong Yang, the Chairman of ICIM and a Fellow of the Chinese Academy of Engineering emphasized that AI (artificial intelligence) was currently accelerating the digital transformation of high-end equipment industry. AI-enabled mechanism and data hybrid-driven method has great potential to cope with the challenges faced by high-end equipment industry such as huge amount of heterogeneous data, slow utilization of unstructured knowledge, and complexity in merging multi-disciplinary mechanism models. He pointed out that by combining massive data and analyzing complex industrial processes through AI technology, a more efficient and accurate way of decision-making and optimization can be realized. Building a unified digital foundation and integrating foundation models with industrial data and mechanism is crucial for significantly improving the intelligence of the entire chain such as engineering, manufacturing, and operation and maintenance.

Figure 2 Huayong Yang, the Chairman of ICIM and a Fellow of the Chinese Academy of Engineering

Figure 3 AI-based large models giving birth to a new round of technological innovation and industrial transformation

Professor Kusiak of the University of Iowa presented ten different scenarios of future intelligent manufacturing and recent developments in digital manufacturing. He stated that the ongoing transformation of manufacturing and the growing volume and flow rate of data across an enterprise will lead to a greater connectivity and interoperability. Sharing resources across manufacturing chains will become a common practice. Autonomous repair is a trend. Meanwhile, cybersecurity and safety issues will still remain a challenge. In addition, manufacturing is moving in two different directions: integration and openness. The integrated manufacturing is driven by new material, new process, and new products. While the open manufacturing architecture is achieved through globally distributed many-to-many production facilities, and re-configurability can be enhanced through manufacturing models in the cloud. Professor Kusiak said that predictive models can be applied to multiple processes in manufacturing, including condition monitoring, fault prediction, and process control etc. Although the scope of application is broad, the AI-based modeling process has significant challenges, such as model complexity, model interpretability, and model reuse.

Figure 4 Professor Andrew Kusiak

Professor Peter Sachsenmeier, Fellow of German National Academy for Science and Engineering shared the lecture "Successful Implementation of Industry 4.0/Intelligent Manufacturing". In this lecture, Professor Sachsenmeier expounded on the true essence of German Industry 4.0. He emphasized that Industry 4.0 is not a goal, but a way alone which we move and the value of Industry 4.0 comes from not technology alone but innovative products, services, and especially new business models. He also demonstrated some typical applications of AI in improving production efficiency, quality inspection and market forecasting. In regarding supply chain challenges, Professor Sachsenmeier proposed eight insights: build up resilience, change the logistics chain to more local production, develop digital business models, pursue lifelong education, engage with the biotech revolution, make friends with al, machine learning, and robotics, embrace the climate change debate, and collaborate across disciplines, organizations, sectors.

Figure 5 Professor Peter Sachsenmeier, Fellow of German National Academy for Science and Engineering

Figure 6 8 insights proposed by Professor Sachsenmeier

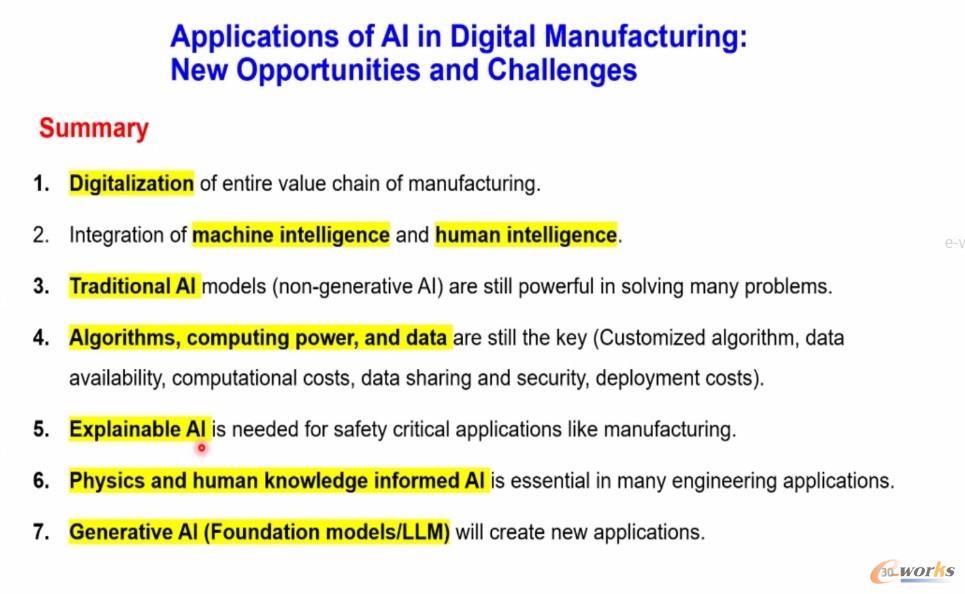

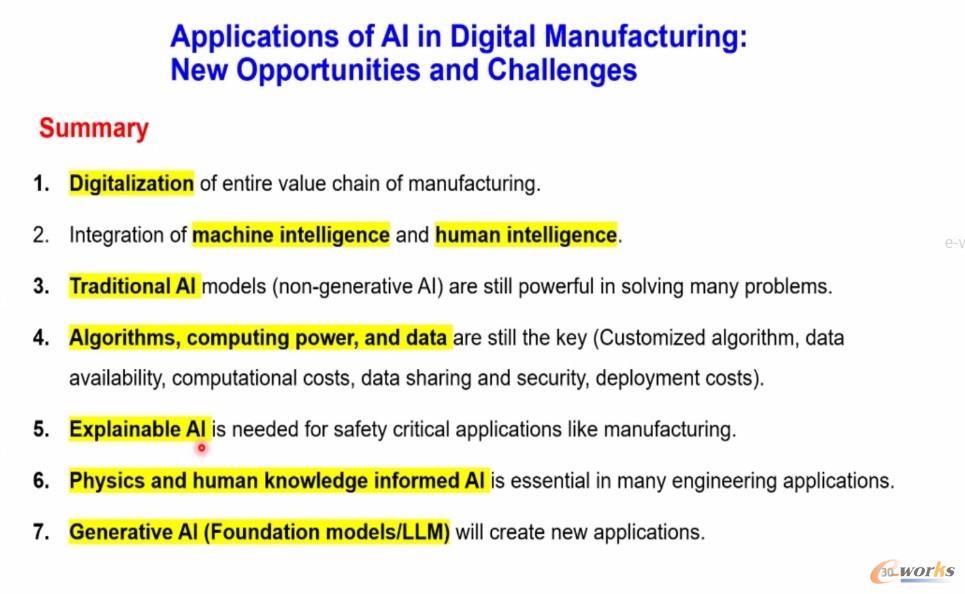

Dr. Min Xia, Associate Professor at Western University deeply analyze the opportunities and challenges of applying AI in digital manufacturing and introduced applications of AI in additive manufacturing, process monitoring, extreme environment operations, combining with specific cases. He said that AI has great potential in improving production efficiency, optimizing manufacturing processes, reducing energy costs and maximizing productivity. For example, to use generative AI for analyzing machine logs, building data models with generative AI for automated data analysis, understanding technical manuals. At the same time, AI applications also faced practical problems such as data security and privacy, algorithm transparency, and workforce disruption. Professor Xia called for deep global cooperation to promote the continuous innovation and jointly cope with these challenges. He summarized that the application trends of AI in manufacturing will be the integration of machine intelligence and human intelligence, the enhanced digitalization of the entire value chain, and physical AI etc.

Figure 7 Min Xia, Associate Professor at Western University

Figure 8 Applications trends of AI in manufacturing (opportunities and challenges)

Professor Yuchun Xu from Aston University shared methods to address sustainable manufacturing through life cycle engineering and optimisation. Professor Xu pointed out that sustainable manufacturing not only includes the manufacturing process, but also the entire life cycle of the product, including monitoring, maintenance, optimization and recycling, and also the supply chain and the user, which needed to be considered and dealt with from multiple dimensions, multiple stages and multiple departments to achieve efficient utilization of resources and reduce waste. He pointed out that the ultimate pursuit of product life cycle optimization is to minimize the whole-life cost while delivering product quality and service level that customers require. This means the continuous optimization of product design, production, and energy consumption and need to balance the cost, quality and time. Enterprises have to minimize life cycle costs while ensuring quality and service, and deeply integrate digital technology to promote sustainable manufacturing.

Figure 9 Professor Yuchun Xu from Aston University

Professor Emeritus David W. Rosen from Georgia Institute of Technology introduced application of machine learning in manufacturing, including accurately classifying and optimizing manufacturing processes through 3D CNN (Convolutional Neural Network) in additive manufacturing; the fusion of conditional Generative Adversarial Networks (cGAN) and topology optimization to realize generative design that both meets functional requirements and efficient optimization; to use CNN and cGAN to realize Design for Manufacturing. Professor Rosen said that by combining DFF with DFM, both the functionality and manufacturability can be realized through iterations by DFF and DFM modules.

Figure 10 Professor Emeritus David W. Rosen of Georgia Institute of Technology

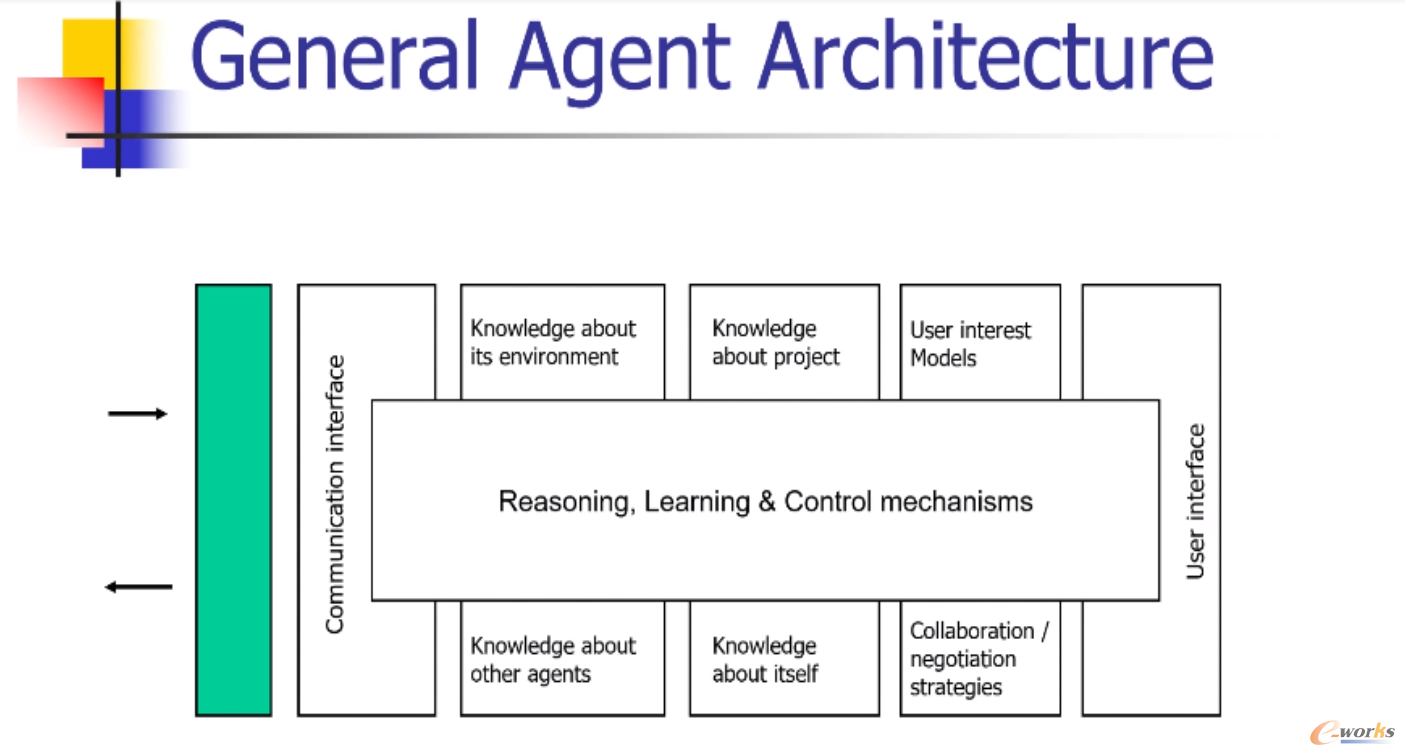

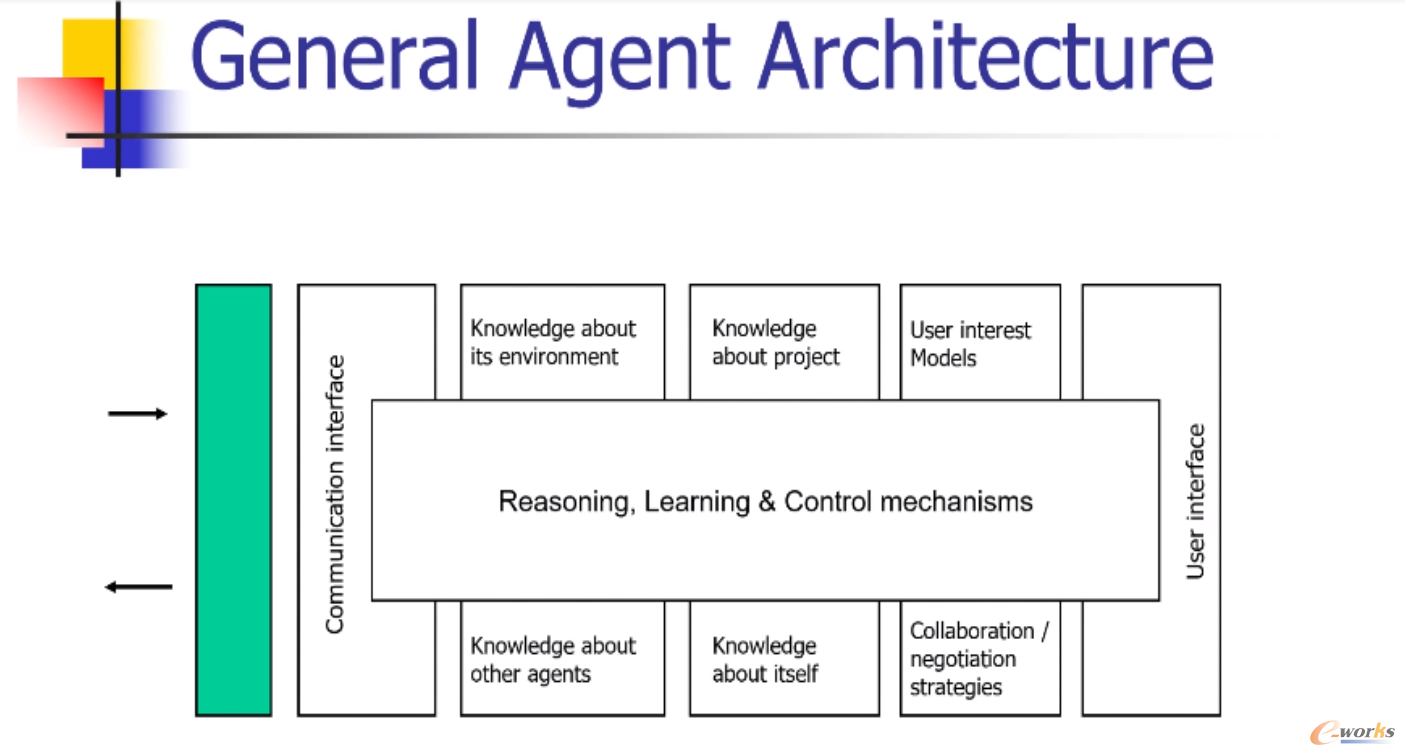

Professor Weiming Shen, Fellow of the Canadian Academy of Engineering, Professor of Huazhong University of Science and Technology (HUST) and the Vice-Chair of ICIM Academic Committee comprehensively introduced the intelligent agent technology, the differences between agents and multi-agent systems, and the features of agents and the applications at five different levels: machine level, shop floor/plant level, enterprise level, supply chain level and after-sales service level. He pointed out that agents are divided into physical and functional agents, which are used to control physical manufacturing resources and used for troubleshooting and production scheduling respectively. The main features of agents are autonomous, proactive, collaborative, fault tolerant and self-healing. The general architecture of an agent includes the layer of learning, control, and reasoning mechanisms, as well as the layers of perception, transmission and execution. With the continuous advancement of technology and its application, this architecture has been further enriched and expanded. A multi-agent system is “a loosely coupled network of problem solvers that work together to solve problems that are beyond their individual capabilities”. Professor Shen emphasized that the combination of agents with advanced technologies such as the Internet of Things and big data will greatly enhance system performance and the integration of industrial large models with agents will be a future trend.

Figure 11 Professor Weiming Shen, Fellow of Canadian Academy of Engineering, Professor of HUST

Figure 12 General agent architecture

Professor Chunsheng Yang, Fellow of the Canadian Academy of Engineering (FCAE) and President of the School of Artificial Intelligence, Guangzhou University, based on his in-depth research in artificial intelligence (AI) and Prognostic and Health Management (PHM) analyzed the latest progress and applications of PHM and AI. He said that data-driven approaches are much promising in coping with uncertainty of complex systems. AI technologies can extract useful information from large amount of data, which is helpful for leveraging a data-driven method to build prediction models therefore to finally realize failure prediction. However, in practice there are still many challenges in the full realization of PHM, such as technologies, business models as well as to the balance of the accuracy of the model with false alarm rate. In the implementation process, it is necessary to deeply understand user requirements and provide customized solutions.

Figure 13 Professor Chunsheng Yang, Fellow of the Canadian Academy of Engineering (FCAE), President of the School of Artificial Intelligence, Guangzhou University

Industry experts gather to share an intelligent future

Mr. Dong Li, Head of Smart Manufacturing Innovation Center of Rockwell Automation China shared his lecture on “Global Industrial Chain of AI-empowered Green and Digital Transformation”. He said that China's manufacturing industry is moving towards a new stage of globalization, together with global industrial chain constantly restructured and upgrading, and the growing importance of sustainable development within enterprises. In this process, enterprises must rely on technological innovation, especially the leverage of advanced technologies such as artificial intelligence, green technology and digital technology, to realize sustainable and low-carbon development. He emphasized that empowering the manufacturing industry with AI will break through the breakpoints from scientific innovation to technology implementation and achieve high-quality development of manufacturing industry.

Figure 14 Mr. Dong Li, Head of Smart Manufacturing Innovation Center of Rockwell Automation China

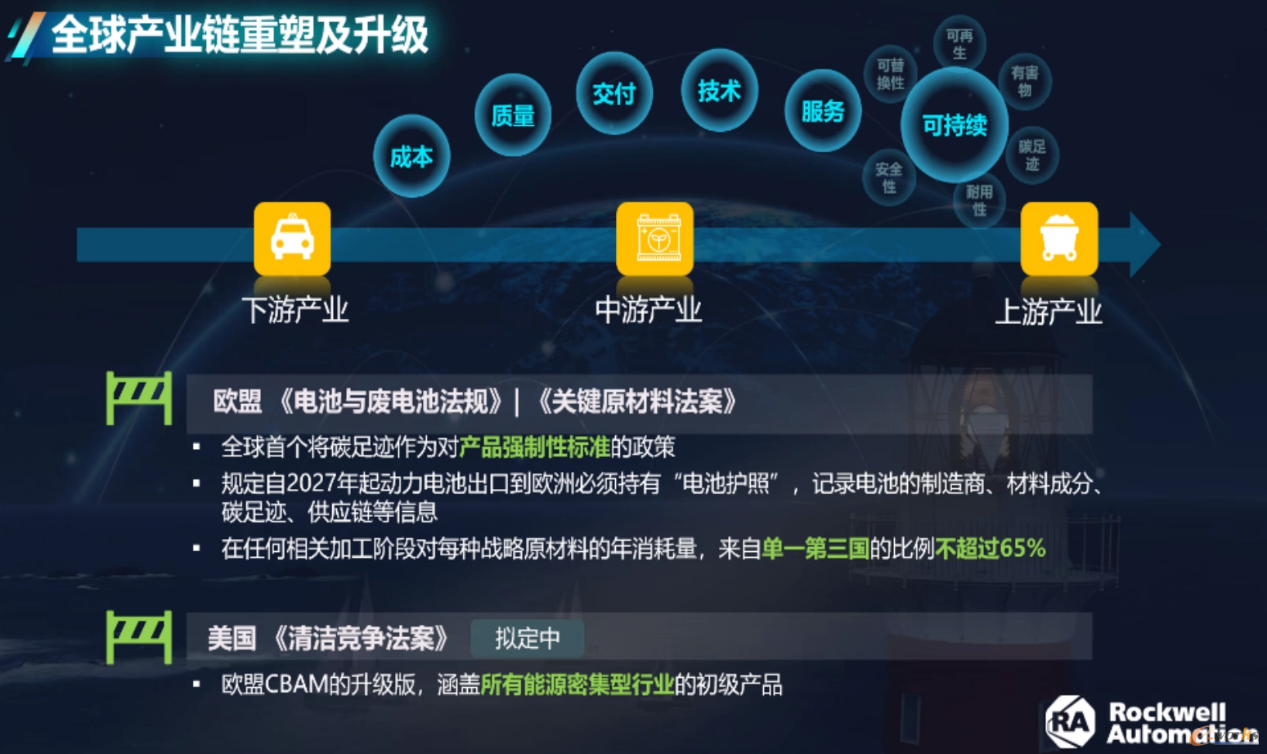

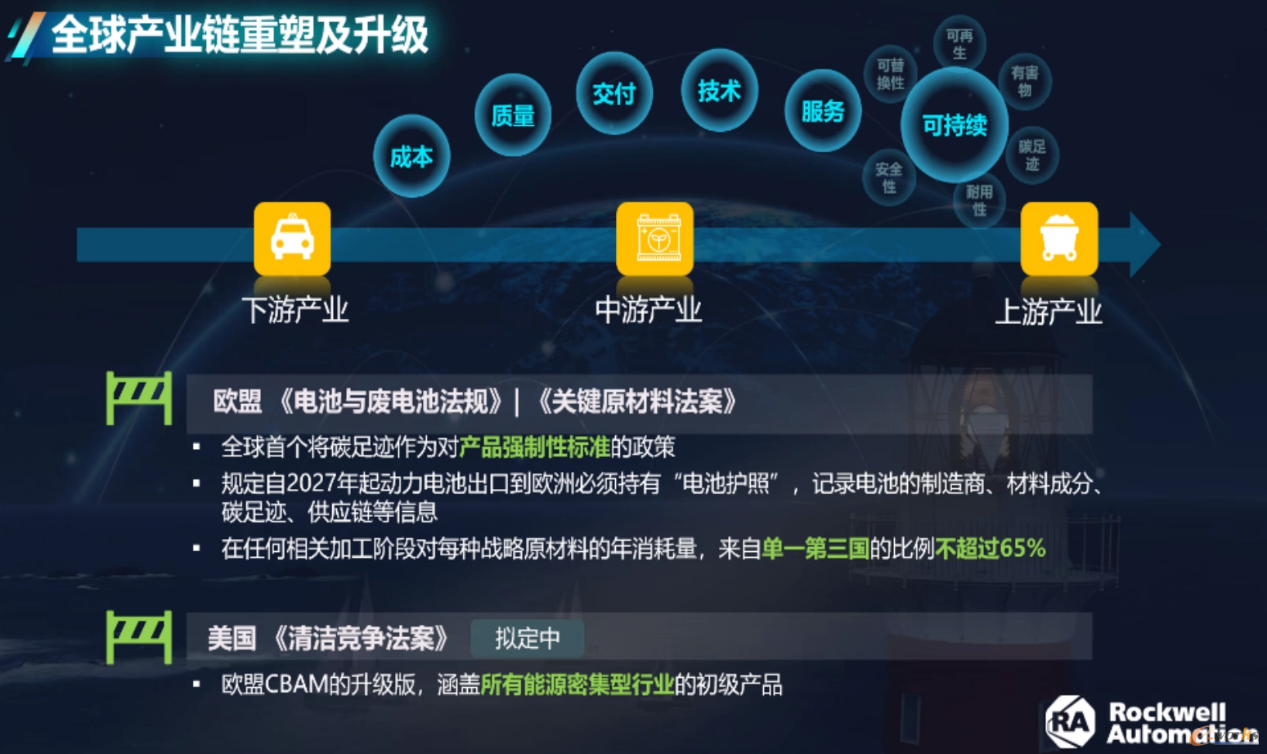

Figure 15 Global industrial chain analysis

Ms. Zihan Luo, Team Leader of the Industrial Edge and AI Solutions, Factory Automation Division, Siemens Digital Industries China shared a speech on Industrial AI Help Chinese Manufacturing Transforming Quantity to Quality. She introduced that industrial AI combined data-driven method can deal with complex problems such as nonlinearity that cannot be solved through traditional methods and used specific cases to demonstrate the application of AI in production processes. She said that by using advanced IT technology to build an open platform and deeply integrating IT with OT, it can provide software and data services that are easier to expand and more flexible for the OT side, ultimately leading to an improvement in process and product quality.

Figure 16 Ms. Zihan Luo, Team Leader of the Industrial Edge and AI Solutions, Factory Automation Division, Siemens Digital Industries China

Mr. Jianlei Li, Director of Solution Development and Operation, Hexagon Intelligent Manufacturing Research Institute shared a speech on the future of manufacturing from the perspective of new quality productivity: from data-driven approach to intelligent manufacturing. He said that it is crucial to build a data-driven intelligent closed-loop system to enable a full data chain connecting data across all processes from design to operation and maintenance. This requires a close connection of people, machines, materials, methods, and the environment as well as technologies like AI, 5G, and big data to improve the automation of the supply chain and autonomy of the system. He pointed out that quality-based intelligent manufacturing is the core of digital transformation. The key of building an intelligent factory is data collection and connectivity, including to connect the digital world with the physical world.

Figure 17 Mr. Jianlei Li, Director of Solution Development and Operation, Hexagon Intelligent Manufacturing Research Institute

Figure 18 Building a data-driven intelligent closed-loop information system

Discrete Manufacturing MOM Expert Wenchao Sun gave a talk around MOM system in intelligent manufacturing. He pointed out that the building of a MOM system follows an incremental process, starting from collecting data automatically at the bottom, then move from automatic shift of machining process, efficient scheduling of multiple threads and performance evaluation to resource optimization and full traceability, finally to the smart management with advanced planning and scheduling. Enterprises need to have a deep look based on their strategy, the maturity level, the key problems, and then design a tailored implementation plan, and estimate the ROI, making sure the MOM system both keeping up with the industry trend and also suiting the real situation and of the enterprise. He also pointed out that the integration of MOM and lean methods is the key to promote manufacturing upgrading.

Figure 19 Wenchao Sun, Discrete Manufacturing MOM Expert, Beijing-Fanuc Mechatronics Co., Ltd.

Exchange of thoughts reveals the future trend

This series of lectures deeply explores the cutting-edge technology in intelligent manufacturing, innovative ideas and many practical cases, laying a solid foundation for digital transformation and upgrading of manufacturing enterprises. It also reveals some future trends of intelligent manufacturing:

1. The integration of AI and manufacturing technologies speeding up

The integration of artificial intelligence and manufacturing technologies continues to accelerate. Artificial intelligence has injected new vitality and possibility into manufacturing with its powerful data processing capacity, self-learning and optimization ability.

2. Ecosystem a priority in promoting intelligent manufacturing

To promote the development of intelligent manufacturing, it is necessary to build an ecosystem in an all-round way, including promoting the close cooperation of upstream and downstream enterprises, strengthening international cooperation and exchange; training innovative high-skilled talents through cooperating with universities, scientific research institutions and enterprises. In this ecosystem, enterprises, suppliers, customers, scientific research institutions and other parties will work closely together to form a good situation of collaborative innovation and mutual benefit.

3. Digital transformation enables green manufacturing

With the global concern for environmental protection and sustainable development, manufacturing enterprises will pay more attention to strengthening technological as well as management innovation, and to use digital technology to promote green transformation. For example, the use of materials, energy consumption and emissions can be reduced through the application of topology optimization and other technologies in the manufacturing process.

4. Predictive maintenance will be a general trend

Predictive maintenance is a proactive maintenance strategy, which collects equipment operation data, analyzes and predicts potential failures, and carries out maintenance in advance. It reduces production interruptions and accidents caused by equipment failures, minimizes unexpected downtime, prolongs equipment life, and reduces maintenance costs. In the future, it will be normal for fault diagnosis and prediction to integrate with cutting-edge technologies such as AI and big data. For example, through the efficient utilization of big data and machine learning-based prediction models, enterprises can gain an unprecedented accuracy insight into the operation status of complex systems and be able to change from passive response to proactively prevent fault.

5. Digital thread key to building data-driven closed-loop systems

Digital thread is an information framework that connects data flow. Based on this framework, the data of the whole product life cycle, including research and development, supply chain, production, testing, operation and maintenance, can be efficiently integrated to construct a digital network for the full product life cycle. Relying on digital thread and professional technology, data collection and connectivity can be realized to enable an intelligent closed-loop system of the full data chain from design to operation and maintenance, which can break data silos and provide single source of truth for different roles and systems.

Creating a better future together

ICIM lecture series provides an important platform for experts and scholars, enterprise representatives and followers to exchange ideas, share experiences and discuss the future. In discussing the future development, a number of experts stressed the importance of international cooperation and exchange. They pointed out that intelligent manufacturing is a common goal of global manufacturing. By strengthening international cooperation and exchange, sharing experience, and jointly responding to challenges and opportunities, can we accelerate the development of intelligent manufacturing technology, contribute wisdom and strength to the prosperity and development of global manufacturing.

The end of the lectures series marks the perfect end of a grand event that deeply explores the frontier of intelligent manufacturing, stimulates innovative thinking and cross-border cooperation. This event brings together industry elites and scholars and experts. Through wonderful sharing and exchange, it not only reveals the latest trend and technological innovation of intelligent manufacturing, but also stimulates the infinite vision and action power to promote the manufacturing transformation and upgrading and a smart future. It also indicates intelligent manufacturing has set sail for a new era full of innovation and potential.

Figure 1 ""Win-win Cooperation: Intelligent Manufacturing in a Global Vision" lecture series

International scholars discussing the future of intelligent manufacturing

This series of lectures brought together many international intelligent manufacturing experts and industry benchmarks. They had in-depth discussions on the latest progress, technological innovation and future blueprint of intelligent manufacturing. The series covered many popular technologies, such as artificial intelligence, additive manufacturing, digital thread, AI agent, PHM, and MOM as well as leading practices of Industry 4.0 and intelligent manufacturing, and future trends. Each session is full of cutting-edge research and profound insights.

In the lecture "Some Explorations on Digital Transformation of AI-powered Machinery Equipment", Professor Huayong Yang, the Chairman of ICIM and a Fellow of the Chinese Academy of Engineering emphasized that AI (artificial intelligence) was currently accelerating the digital transformation of high-end equipment industry. AI-enabled mechanism and data hybrid-driven method has great potential to cope with the challenges faced by high-end equipment industry such as huge amount of heterogeneous data, slow utilization of unstructured knowledge, and complexity in merging multi-disciplinary mechanism models. He pointed out that by combining massive data and analyzing complex industrial processes through AI technology, a more efficient and accurate way of decision-making and optimization can be realized. Building a unified digital foundation and integrating foundation models with industrial data and mechanism is crucial for significantly improving the intelligence of the entire chain such as engineering, manufacturing, and operation and maintenance.

Figure 2 Huayong Yang, the Chairman of ICIM and a Fellow of the Chinese Academy of Engineering

Figure 3 AI-based large models giving birth to a new round of technological innovation and industrial transformation

Professor Kusiak of the University of Iowa presented ten different scenarios of future intelligent manufacturing and recent developments in digital manufacturing. He stated that the ongoing transformation of manufacturing and the growing volume and flow rate of data across an enterprise will lead to a greater connectivity and interoperability. Sharing resources across manufacturing chains will become a common practice. Autonomous repair is a trend. Meanwhile, cybersecurity and safety issues will still remain a challenge. In addition, manufacturing is moving in two different directions: integration and openness. The integrated manufacturing is driven by new material, new process, and new products. While the open manufacturing architecture is achieved through globally distributed many-to-many production facilities, and re-configurability can be enhanced through manufacturing models in the cloud. Professor Kusiak said that predictive models can be applied to multiple processes in manufacturing, including condition monitoring, fault prediction, and process control etc. Although the scope of application is broad, the AI-based modeling process has significant challenges, such as model complexity, model interpretability, and model reuse.

Figure 4 Professor Andrew Kusiak

Professor Peter Sachsenmeier, Fellow of German National Academy for Science and Engineering shared the lecture "Successful Implementation of Industry 4.0/Intelligent Manufacturing". In this lecture, Professor Sachsenmeier expounded on the true essence of German Industry 4.0. He emphasized that Industry 4.0 is not a goal, but a way alone which we move and the value of Industry 4.0 comes from not technology alone but innovative products, services, and especially new business models. He also demonstrated some typical applications of AI in improving production efficiency, quality inspection and market forecasting. In regarding supply chain challenges, Professor Sachsenmeier proposed eight insights: build up resilience, change the logistics chain to more local production, develop digital business models, pursue lifelong education, engage with the biotech revolution, make friends with al, machine learning, and robotics, embrace the climate change debate, and collaborate across disciplines, organizations, sectors.

Figure 5 Professor Peter Sachsenmeier, Fellow of German National Academy for Science and Engineering

Figure 6 8 insights proposed by Professor Sachsenmeier

Dr. Min Xia, Associate Professor at Western University deeply analyze the opportunities and challenges of applying AI in digital manufacturing and introduced applications of AI in additive manufacturing, process monitoring, extreme environment operations, combining with specific cases. He said that AI has great potential in improving production efficiency, optimizing manufacturing processes, reducing energy costs and maximizing productivity. For example, to use generative AI for analyzing machine logs, building data models with generative AI for automated data analysis, understanding technical manuals. At the same time, AI applications also faced practical problems such as data security and privacy, algorithm transparency, and workforce disruption. Professor Xia called for deep global cooperation to promote the continuous innovation and jointly cope with these challenges. He summarized that the application trends of AI in manufacturing will be the integration of machine intelligence and human intelligence, the enhanced digitalization of the entire value chain, and physical AI etc.

Figure 7 Min Xia, Associate Professor at Western University

Figure 8 Applications trends of AI in manufacturing (opportunities and challenges)

Professor Yuchun Xu from Aston University shared methods to address sustainable manufacturing through life cycle engineering and optimisation. Professor Xu pointed out that sustainable manufacturing not only includes the manufacturing process, but also the entire life cycle of the product, including monitoring, maintenance, optimization and recycling, and also the supply chain and the user, which needed to be considered and dealt with from multiple dimensions, multiple stages and multiple departments to achieve efficient utilization of resources and reduce waste. He pointed out that the ultimate pursuit of product life cycle optimization is to minimize the whole-life cost while delivering product quality and service level that customers require. This means the continuous optimization of product design, production, and energy consumption and need to balance the cost, quality and time. Enterprises have to minimize life cycle costs while ensuring quality and service, and deeply integrate digital technology to promote sustainable manufacturing.

Figure 9 Professor Yuchun Xu from Aston University

Professor Emeritus David W. Rosen from Georgia Institute of Technology introduced application of machine learning in manufacturing, including accurately classifying and optimizing manufacturing processes through 3D CNN (Convolutional Neural Network) in additive manufacturing; the fusion of conditional Generative Adversarial Networks (cGAN) and topology optimization to realize generative design that both meets functional requirements and efficient optimization; to use CNN and cGAN to realize Design for Manufacturing. Professor Rosen said that by combining DFF with DFM, both the functionality and manufacturability can be realized through iterations by DFF and DFM modules.

Figure 10 Professor Emeritus David W. Rosen of Georgia Institute of Technology

Professor Weiming Shen, Fellow of the Canadian Academy of Engineering, Professor of Huazhong University of Science and Technology (HUST) and the Vice-Chair of ICIM Academic Committee comprehensively introduced the intelligent agent technology, the differences between agents and multi-agent systems, and the features of agents and the applications at five different levels: machine level, shop floor/plant level, enterprise level, supply chain level and after-sales service level. He pointed out that agents are divided into physical and functional agents, which are used to control physical manufacturing resources and used for troubleshooting and production scheduling respectively. The main features of agents are autonomous, proactive, collaborative, fault tolerant and self-healing. The general architecture of an agent includes the layer of learning, control, and reasoning mechanisms, as well as the layers of perception, transmission and execution. With the continuous advancement of technology and its application, this architecture has been further enriched and expanded. A multi-agent system is “a loosely coupled network of problem solvers that work together to solve problems that are beyond their individual capabilities”. Professor Shen emphasized that the combination of agents with advanced technologies such as the Internet of Things and big data will greatly enhance system performance and the integration of industrial large models with agents will be a future trend.

Figure 11 Professor Weiming Shen, Fellow of Canadian Academy of Engineering, Professor of HUST

Figure 12 General agent architecture

Professor Chunsheng Yang, Fellow of the Canadian Academy of Engineering (FCAE) and President of the School of Artificial Intelligence, Guangzhou University, based on his in-depth research in artificial intelligence (AI) and Prognostic and Health Management (PHM) analyzed the latest progress and applications of PHM and AI. He said that data-driven approaches are much promising in coping with uncertainty of complex systems. AI technologies can extract useful information from large amount of data, which is helpful for leveraging a data-driven method to build prediction models therefore to finally realize failure prediction. However, in practice there are still many challenges in the full realization of PHM, such as technologies, business models as well as to the balance of the accuracy of the model with false alarm rate. In the implementation process, it is necessary to deeply understand user requirements and provide customized solutions.

Figure 13 Professor Chunsheng Yang, Fellow of the Canadian Academy of Engineering (FCAE), President of the School of Artificial Intelligence, Guangzhou University

Industry experts gather to share an intelligent future

Mr. Dong Li, Head of Smart Manufacturing Innovation Center of Rockwell Automation China shared his lecture on “Global Industrial Chain of AI-empowered Green and Digital Transformation”. He said that China's manufacturing industry is moving towards a new stage of globalization, together with global industrial chain constantly restructured and upgrading, and the growing importance of sustainable development within enterprises. In this process, enterprises must rely on technological innovation, especially the leverage of advanced technologies such as artificial intelligence, green technology and digital technology, to realize sustainable and low-carbon development. He emphasized that empowering the manufacturing industry with AI will break through the breakpoints from scientific innovation to technology implementation and achieve high-quality development of manufacturing industry.

Figure 14 Mr. Dong Li, Head of Smart Manufacturing Innovation Center of Rockwell Automation China

Figure 15 Global industrial chain analysis

Ms. Zihan Luo, Team Leader of the Industrial Edge and AI Solutions, Factory Automation Division, Siemens Digital Industries China shared a speech on Industrial AI Help Chinese Manufacturing Transforming Quantity to Quality. She introduced that industrial AI combined data-driven method can deal with complex problems such as nonlinearity that cannot be solved through traditional methods and used specific cases to demonstrate the application of AI in production processes. She said that by using advanced IT technology to build an open platform and deeply integrating IT with OT, it can provide software and data services that are easier to expand and more flexible for the OT side, ultimately leading to an improvement in process and product quality.

Figure 16 Ms. Zihan Luo, Team Leader of the Industrial Edge and AI Solutions, Factory Automation Division, Siemens Digital Industries China

Mr. Jianlei Li, Director of Solution Development and Operation, Hexagon Intelligent Manufacturing Research Institute shared a speech on the future of manufacturing from the perspective of new quality productivity: from data-driven approach to intelligent manufacturing. He said that it is crucial to build a data-driven intelligent closed-loop system to enable a full data chain connecting data across all processes from design to operation and maintenance. This requires a close connection of people, machines, materials, methods, and the environment as well as technologies like AI, 5G, and big data to improve the automation of the supply chain and autonomy of the system. He pointed out that quality-based intelligent manufacturing is the core of digital transformation. The key of building an intelligent factory is data collection and connectivity, including to connect the digital world with the physical world.

Figure 17 Mr. Jianlei Li, Director of Solution Development and Operation, Hexagon Intelligent Manufacturing Research Institute

Figure 18 Building a data-driven intelligent closed-loop information system

Discrete Manufacturing MOM Expert Wenchao Sun gave a talk around MOM system in intelligent manufacturing. He pointed out that the building of a MOM system follows an incremental process, starting from collecting data automatically at the bottom, then move from automatic shift of machining process, efficient scheduling of multiple threads and performance evaluation to resource optimization and full traceability, finally to the smart management with advanced planning and scheduling. Enterprises need to have a deep look based on their strategy, the maturity level, the key problems, and then design a tailored implementation plan, and estimate the ROI, making sure the MOM system both keeping up with the industry trend and also suiting the real situation and of the enterprise. He also pointed out that the integration of MOM and lean methods is the key to promote manufacturing upgrading.

Figure 19 Wenchao Sun, Discrete Manufacturing MOM Expert, Beijing-Fanuc Mechatronics Co., Ltd.

Exchange of thoughts reveals the future trend

This series of lectures deeply explores the cutting-edge technology in intelligent manufacturing, innovative ideas and many practical cases, laying a solid foundation for digital transformation and upgrading of manufacturing enterprises. It also reveals some future trends of intelligent manufacturing:

1. The integration of AI and manufacturing technologies speeding up

The integration of artificial intelligence and manufacturing technologies continues to accelerate. Artificial intelligence has injected new vitality and possibility into manufacturing with its powerful data processing capacity, self-learning and optimization ability.

2. Ecosystem a priority in promoting intelligent manufacturing

To promote the development of intelligent manufacturing, it is necessary to build an ecosystem in an all-round way, including promoting the close cooperation of upstream and downstream enterprises, strengthening international cooperation and exchange; training innovative high-skilled talents through cooperating with universities, scientific research institutions and enterprises. In this ecosystem, enterprises, suppliers, customers, scientific research institutions and other parties will work closely together to form a good situation of collaborative innovation and mutual benefit.

3. Digital transformation enables green manufacturing

With the global concern for environmental protection and sustainable development, manufacturing enterprises will pay more attention to strengthening technological as well as management innovation, and to use digital technology to promote green transformation. For example, the use of materials, energy consumption and emissions can be reduced through the application of topology optimization and other technologies in the manufacturing process.

4. Predictive maintenance will be a general trend

Predictive maintenance is a proactive maintenance strategy, which collects equipment operation data, analyzes and predicts potential failures, and carries out maintenance in advance. It reduces production interruptions and accidents caused by equipment failures, minimizes unexpected downtime, prolongs equipment life, and reduces maintenance costs. In the future, it will be normal for fault diagnosis and prediction to integrate with cutting-edge technologies such as AI and big data. For example, through the efficient utilization of big data and machine learning-based prediction models, enterprises can gain an unprecedented accuracy insight into the operation status of complex systems and be able to change from passive response to proactively prevent fault.

5. Digital thread key to building data-driven closed-loop systems

Digital thread is an information framework that connects data flow. Based on this framework, the data of the whole product life cycle, including research and development, supply chain, production, testing, operation and maintenance, can be efficiently integrated to construct a digital network for the full product life cycle. Relying on digital thread and professional technology, data collection and connectivity can be realized to enable an intelligent closed-loop system of the full data chain from design to operation and maintenance, which can break data silos and provide single source of truth for different roles and systems.

Creating a better future together

ICIM lecture series provides an important platform for experts and scholars, enterprise representatives and followers to exchange ideas, share experiences and discuss the future. In discussing the future development, a number of experts stressed the importance of international cooperation and exchange. They pointed out that intelligent manufacturing is a common goal of global manufacturing. By strengthening international cooperation and exchange, sharing experience, and jointly responding to challenges and opportunities, can we accelerate the development of intelligent manufacturing technology, contribute wisdom and strength to the prosperity and development of global manufacturing.

The end of the lectures series marks the perfect end of a grand event that deeply explores the frontier of intelligent manufacturing, stimulates innovative thinking and cross-border cooperation. This event brings together industry elites and scholars and experts. Through wonderful sharing and exchange, it not only reveals the latest trend and technological innovation of intelligent manufacturing, but also stimulates the infinite vision and action power to promote the manufacturing transformation and upgrading and a smart future. It also indicates intelligent manufacturing has set sail for a new era full of innovation and potential.