IMTS 2022: What’s New at North America’s Largest Manufacturing Trade Show

Featuring exhibits that range from automation and CNC machining to 3D printing, IMTS is back with a bang.

The International Manufacturing Technology Show (IMTS) is back after a four-year hiatus. Typically held every two years, North America’s largest manufacturing trade show was canceled in 2020 due to the COVID-19 pandemic. This year’s event promises to compensate for the absence.

Over 1,200 exhibitors are at McCormick Place in Chicago, Illinois to display their latest solutions, from CNC machining and injection molding to on-demand 3D printing services. In fact, the additive manufacturing presence at this year’s show is relatively larger than in previous years—with 83 3D printing exhibitors representing more than double the number that participated in 2018’s event.

Here’s what’s new at IMTS 2022.

Nexa3D: LSPc, NXE Pro, QLS 820 and Materials

Nexa3D showcased their new Lubricant Sublayer Photo-curing (LSPc) technology at IMTS. The company also released their NXE Pro series and QLS 820 3D printers, along with new printing resins for a variety of applications.

HP: S100 Metal Jet 3D Printer

HP launched their S100 Metal Jet 3D printer at IMTS. The company appears to be banking on the growing opportunities within the world of metal additive manufacturing.

“The natural evolution for us was going into metals,” said Ramon Pastor, Global Head and General Manager at HP, during a press briefing. “The opportunities are huge—but to realize these opportunities, several things need to happen.”

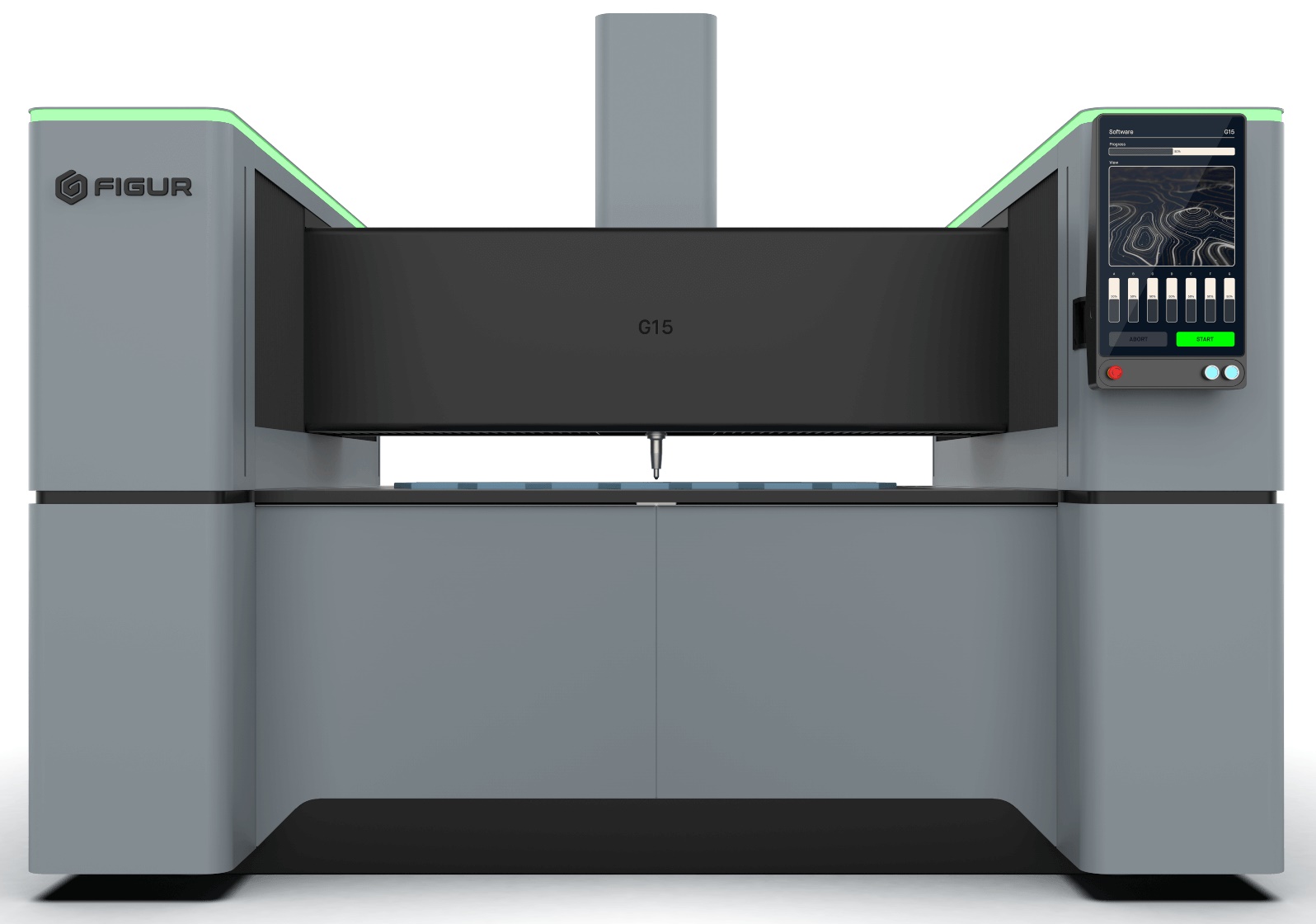

Desktop Metal: Figur G15

Additive manufacturing leader Desktop Metal used the IMTS trade show to launch the Figur G15, the first commercial platform of its kind for digital sheet metal shaping and building. Employing a patent-pending Digital Sheet Forming (DSF) technology, the G15 uses a digital design file to build parts out of sheet metal. This allows production to circumvent time-consuming, expensive processes such as custom-forming, presses, stamping tools, dies or molds that are used in conventional sheet metal manufacturing.

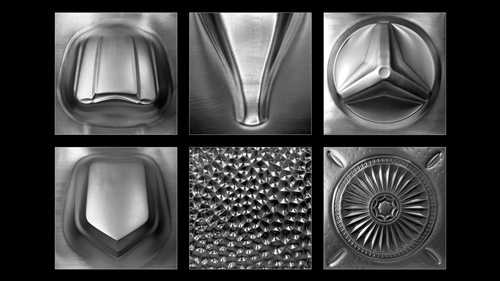

The Figur G15’s DSF technology. (Photo: Business Wire)

During a build, the G15’s software-guided ceramic tool head forms metal sheets one layer at a time using a force of up to 2,000 pounds. The proprietary build box design features a forming area of 1450 x 1000 x 400 mm and can produce steel sheets up to 2 mm in thickness and aluminum sheets that are 2.5 mm in thickness.

Sheet metal designs produced on the Figur G15. (Photo: Business Wire)

Given the efficiency of production and cost-effectiveness, the company believes there is a wide range of applications for the Figur G15, particularly in the aerospace, automotive and appliance industries.

FANUC: NC Reflection Studio

FANUC is demoing their new NC Reflection Studio at IMTS 2022. The studio boasts highly accurate CNC cutting simulation with backplotting, troubleshooting and part program editing capabilities, as well as a suite of job setups.

Xact Metal: XM300G Metal 3D Printer

Pennsylvania-based Xact Metal launched their latest XM300G metal printer at IMTS 2022. Building upon the XM200G multi-laser printer, the XM300G marks another step towards large-scale metal additive manufacturing that is affordable and supports small- to medium-sized companies.

The XM300G metal 3D printer. (Image courtesy of Xact Metal.)

With customizable single, dual and quad-lasers, the XM300G combines metal laser powder-bed fusion (LPBF) technology with fully overlapping print zones within a build volume as large as 300 x 300 x 450mm. A selection of 400W or 700W fiber lasers are available. Interchangeable build platforms ensure faster print cycles, allowing relatively small-scale manufacturers to print larger metal parts in scalable quantities.

Xact Metal has already generated orders from around the world for the XM300G. Shipments are expected to commence during the third quarter of 2023. The starting price for the XM300G is $200,000.