e-works successfully organized the 10th Industry 4.0 delegation to Germany

On April 8, 2019, the 10th Industry 4.0 delegation to Germany in Spring of 2019, organized by e-works, came to a successful conclusion. Under the leadership of Dr. Pei Huang,CEO of e-works, members of the delegation completed a 10-day in-depth exploration tour.

Group photo of the 10th Industry 4.0 delegation to Germany

The first stop of the delegation was BOSCH. The members visited the Bosch Feuerbach and Reutlingen factories in two groups. Bosch has pragmatically promoted industrial 4.0, realized the deepening application of digital technology in flexible production, energy saving and environmental protection, intelligent maintenance of equipment, man-machine cooperation and so on, which has brought great inspiration to the members of the delegation.

Delegation at Feuerbach Factory

Delegation at Reutlingen Factory

The second stop of the delegation was SEEBURGER. It’s the second time that e-works organized enterprises to visit SEEBURGER. CEO Axel Haas, together with Mr. Huang Gang, General Manager of China and Frank Stegmueller, Vice President of Marketing and Services Department, warmly welcomed the delegation. SEEBURGER is a leading provider of business integration platforms. HIP (Hybrid Integration Platform) launched by SEEBURGER can connect application systems within and between enterprises, to realize application integration and electronic data exchange. It can also integrate data from the edge to the cloud, to realize the integration of data and application systems of many industries.

Axel Haas introducing the latest developments in SEEBURGER

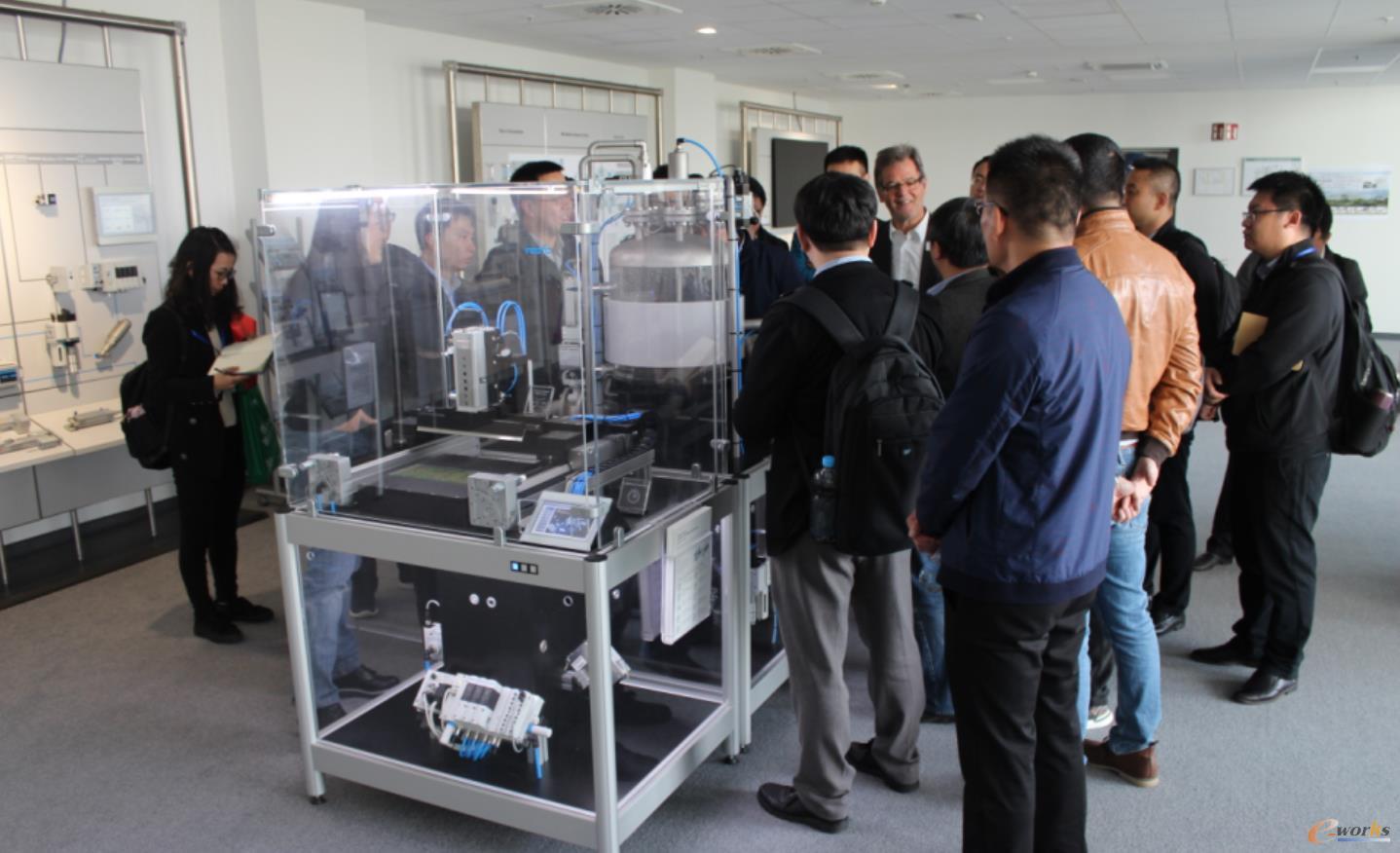

The delegation visited the Festo Scharnhausen factory at the third stop, which is Festo's leading plant in the fields of valves, valve terminal and electronic technology. Festo evaluates the application maturity of each key process by using industry 4.0 evaluation system. The automatic assembly line of valve body can assemble 50 variants automatically. Real-time acquisition and predictive maintenance are applied to processing equipment and production line data. Collaborative robots are used as well. Attaching great importance to people-oriented, man-machine cooperation, Festo flexibly adjusts the layout of the workshop, pays attention to staff training, and also has established a lot of innovation space in the factory.

Festo staff introducing the latest valve application

The fourth stop was SEW Eurodrive, a giant transmission equipment company. Its industrial 4.0 strategic plan, Lean Sm@rt Factory, aroused great interest of the members. Marc Schindler, Regional Manager of China, and his colleague Christof Heckmann warmly received the delegation and introduced SEW to the delegation. The delegation visited the SEW Lean Intelligent Factory Planning Demonstration and the SEW Assembly and Machining Workshop. During the visit, the delegates was impressed that SEW had brought the optimization of production process into full play through AGV car and logistics system.

Christof Heckmann introducing the fourth-generation AGV car of SEW

The fifth stop was Industrial 4.0 German National Innovation Center of Darmstadt Technical University. The members listened to the thematic reports on German Industry 4.0. The delegation also visited the Virtual Technology Laboratory of the Innovation Center and Smart Manufacturing Simulated Factory for German SMEs. Industry 4.0 German National Innovation Center is a global service hub and window for governments, enterprises and universities at all levels in the field of industry 4.0 and smart manufacturing.

The Delegation Listening to the Industry 4.0 Practice Guide for German SMEs

Members of the delegation took a bus to visit the sixth stop, BASF, the largest chemical production base in the world. BASF is specialized in six areas: chemicals, materials, industrial solutions, surface treatment technology, nutrition and nursing, agricultural solutions. In Ludwig Harbour, BASF put forward the concept of "responsible use of water resources" , and the water resources management and operation system has been thoroughly implemented and developed. Most of the water in the base is used as cooling water. After use, it will be tested and flow back to the Rhine River without any treatment.

Delegation at BASF Visitor Center

The seventh stop was Fastems Issum factory. FASTEMS is a world-renowned integrated solution provider for factory automation, specializing in manufacturing-oriented flexible manufacturing systems (FMS). Peter Wahner, general manager of the factory, and Mr. Teemu-Pekka Ahonen, product manager, warmly received the delegation. The delegation observed several flexible manufacturing units and automatic loading and unloading systems to be delivered. Fastems is committed to helping manufacturing enterprises improve OEE of CNC equipment, aiming at 8760 hours a year. The highest record has reached 8000 hours a year for machine tool spindles.

Mr. Peter Wahner introducing Fastems solutions

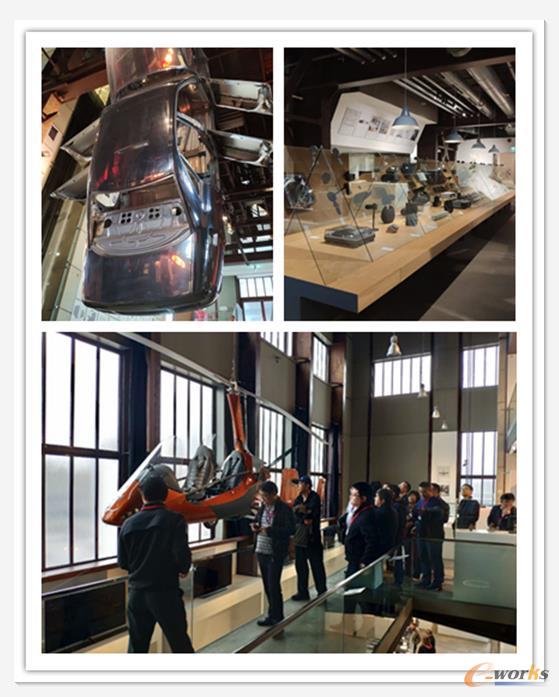

The delegation visited the Red Point Design Museum in Essen, Germany at the eighth stop. Established in the 1960s, the museum was transformed from an abandoned coal mine factory and is a gathering place of the world's top design. Every year, more than 12,000 works take part in the competition. According to the four criteria of function, aesthetics, use and responsibility, 39 judges from all over the world select the winning works, which are awarded the "Red Spot Award". Being in the midst of all kinds of aesthetic design works, the members of the delegation who attended the exhibition seemed to be in the infinite future space of creativity.

Red Point Design Museum

Delegation seeing the star exhibits “best of best”

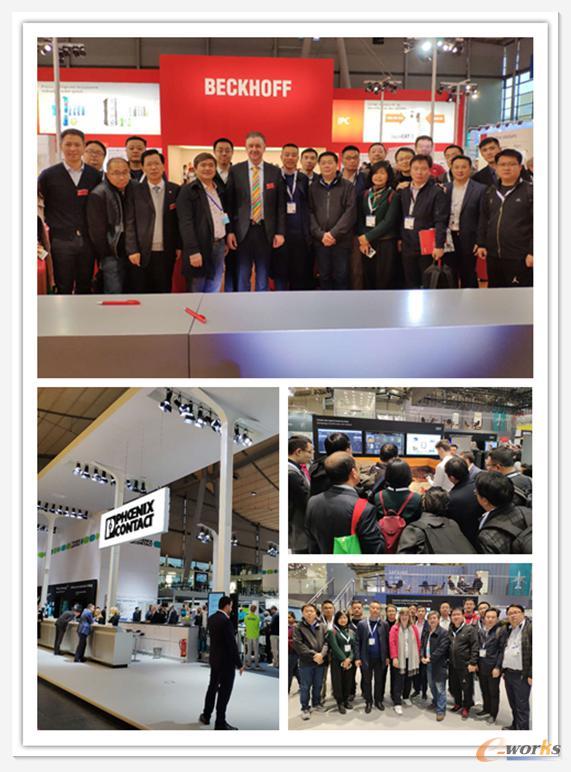

The delegation visited the Hanover Industrial Exhibition. The theme of this trade fair is "Industrial Intelligence, Integrative Industrial". It attracted 6,500 exhibitors from 75 countries and regions around the world to participate in the exhibition, displaying the bright spots of industrial Internet of Things applications, industrial big data analysis, predictive maintenance, digital twin applications and so on. The e-works delegation reserved several booths, such as Beifu, SICK, SAP and IBM to give in-depth explanations, which impressed the members of the delegation. In addition, the delegation also visited Siemens, Phoenix, Dassault Systems, AWS, ABB, Autodesk, Huawei, Splunk and other exhibition booths. The latest solutions presented by the manufacturers became the vane of industrial development, which benefited the members of the delegation greatly.

The delegation attending Hanover Industrial Exhibition

Through close factory visits, technical lectures, question-and-answer sessions and internal discussions, the delegation members deeply appreciated the German spirit of practicality, perseverance and excellence, and gained a deeper understanding of how to achieve lean production, human-machine collaboration and flexible automation production line applications in promoting smart factories. New understanding of new technologies such as digital twin, big data, edge computing, artificial intelligence and so on provides valuable experience for enterprises to promote smart manufacturing and industrial 4.0.Adhering to e-works's consistent way of "getting off and visiting, getting on and discussing", the members of the delegation spared no effort to share their experience and insights during the inspection. The members of the delegation highly appraised the e-works inspection arrangement and agreed that it was a journey of harvest and ingenuity.

Members of the delegation sharing their experiences and insights

As a third-party professional service organization dedicated to promoting smart manufacturing, e-works will continue to provide opportunities for manufacturers to study and exchange abroad. In 2019, in addition to organize delegations to Japan, Germany, and the United States, e-works will also open study tours to Western Europe (Netherlands, Belgium, France), Southern Europe (Switzerland, Italy), Taiwan, and Israel. We sincerely look forward to going together with you to explore world-renowned manufacturing companies and industrial software companies.Special report about this event:http://www.e-works.net.cn/report/2019germany_rp/2019germany_rp.html

Members toasting to celebrate the successful conclusion of the inspection