Simulation helps VP Automation reduce costs by a factor of 10

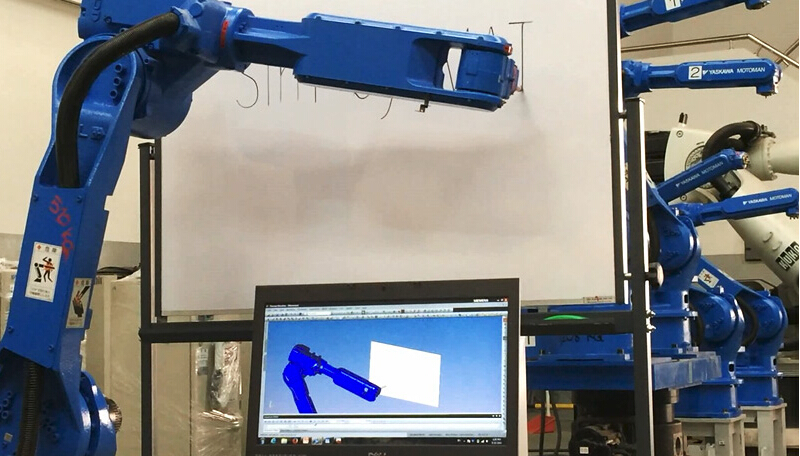

VP Automation Systems Co., Ltd. (VP Automation) is using the Process Simulate solution in the Tecnomatix® portfolio from product lifecycle management (PLM) provider Siemens PLM Software to help automate changes to robotic systems on the manufacturing floor.

Using Tecnomatix helps VP Automation improve customer service

The company is a leading supplier of robot services and solutions, renovating, installing and modifying robotic systems for customers throughout Thailand.

Using Process Simulate, VP Automation can simulate and subsequently implement new model changes without disturbing a customer's production process. While engineers once spent time designing and evaluating each new model change in the robot lines according to each customer's requirements, they now simulate these changes virtually. This enables them to quickly and intuitively build logistics models and perform sophisticated production analysis. Engineers can easily author, re-use, validate and optimize manufacturing process sequences. "With Process Simulate, everything happens correctly the first time," says Kachantkit.

Improved productivity means more satisfied customers

Prior to using Process Simulate, VP Automation modeled and deployed robot changes without a robot programming platform. Addressing production changes individually was time-consuming and frustrating. To make each change, production had to be stopped for a manual setup, wasting time and resources.

"Using Process Simulate to simulate and design line automation, we can match the right model the first time, shortening production line planning time while improving efficiency," Kachantkit explains. "It has also helped us respond faster to last-minute changes from clients and meet our deadlines. It's now much easier to explain decisions to customers and show them product planning details ahead of time, improving process planning."

Process Simulate enables VP Automation to discover and mitigate problems before they arise through the software's ability to design and validate manufacturing processes in a fully integrated, dynamic, 3D data-managed environment. Manufacturing engineers can create digital models of production systems in advance, run experiments and explore "what-if" scenarios without disturbing existing production systems.

"With its extensive analysis capabilities that enable us to evaluate different manufacturing scenarios, Process Simulate provides the tools and information we need to make the right decisions during the early stages of production planning," says Kachantkit. Process Simulate also helps speed time-to-market by enabling engineers to virtually validate manufacturing concepts early in the product development process as well as throughout the lifecycle of product introductions. "Process Simulate has helped us significantly improve service quality and strengthened our competitive edge. We are now considered a market leader," he says.

Measurable results that maximize capacity

"Thanks to the ability to detect product design issues early with Process Simulate, we have reduced the cost of each change and shortened new model changing times by a factor of 10," says Kachantkit. The company has also minimized the number of physical prototypes it produces because of the virtual validation functionality of Process Simulate. Improved access to data and functionality that promotes project collaboration among the mechanical design and control departments enables VP Automation to avoid costly mistakes for its customers.

Not only does using Process Simulate help VP Automation reduce process production planning time, it also improves robot solution marketing, which resulted in the company achieving 105 percent of its sales targets. According to VP Automation management, with Process Simulate, the company has gained a notable and important edge in its ability to compete. Kachantkit concludes, "Process Simulate has helped us serve our customers more quickly, more efficiently and with a greater degree of accuracy. These improvements have helped us deliver higher quality and value for our growing customer base, while improving customer satisfaction and enhancing our reputation."

The company is a leading supplier of robot services and solutions, renovating, installing and modifying robotic systems for customers throughout Thailand.

Using Process Simulate, VP Automation can simulate and subsequently implement new model changes without disturbing a customer's production process. While engineers once spent time designing and evaluating each new model change in the robot lines according to each customer's requirements, they now simulate these changes virtually. This enables them to quickly and intuitively build logistics models and perform sophisticated production analysis. Engineers can easily author, re-use, validate and optimize manufacturing process sequences. "With Process Simulate, everything happens correctly the first time," says Kachantkit.

Improved productivity means more satisfied customers

Prior to using Process Simulate, VP Automation modeled and deployed robot changes without a robot programming platform. Addressing production changes individually was time-consuming and frustrating. To make each change, production had to be stopped for a manual setup, wasting time and resources.

"Using Process Simulate to simulate and design line automation, we can match the right model the first time, shortening production line planning time while improving efficiency," Kachantkit explains. "It has also helped us respond faster to last-minute changes from clients and meet our deadlines. It's now much easier to explain decisions to customers and show them product planning details ahead of time, improving process planning."

Process Simulate enables VP Automation to discover and mitigate problems before they arise through the software's ability to design and validate manufacturing processes in a fully integrated, dynamic, 3D data-managed environment. Manufacturing engineers can create digital models of production systems in advance, run experiments and explore "what-if" scenarios without disturbing existing production systems.

"With its extensive analysis capabilities that enable us to evaluate different manufacturing scenarios, Process Simulate provides the tools and information we need to make the right decisions during the early stages of production planning," says Kachantkit. Process Simulate also helps speed time-to-market by enabling engineers to virtually validate manufacturing concepts early in the product development process as well as throughout the lifecycle of product introductions. "Process Simulate has helped us significantly improve service quality and strengthened our competitive edge. We are now considered a market leader," he says.

Measurable results that maximize capacity

"Thanks to the ability to detect product design issues early with Process Simulate, we have reduced the cost of each change and shortened new model changing times by a factor of 10," says Kachantkit. The company has also minimized the number of physical prototypes it produces because of the virtual validation functionality of Process Simulate. Improved access to data and functionality that promotes project collaboration among the mechanical design and control departments enables VP Automation to avoid costly mistakes for its customers.

Not only does using Process Simulate help VP Automation reduce process production planning time, it also improves robot solution marketing, which resulted in the company achieving 105 percent of its sales targets. According to VP Automation management, with Process Simulate, the company has gained a notable and important edge in its ability to compete. Kachantkit concludes, "Process Simulate has helped us serve our customers more quickly, more efficiently and with a greater degree of accuracy. These improvements have helped us deliver higher quality and value for our growing customer base, while improving customer satisfaction and enhancing our reputation."