Fusheng Industrial

Established in 1953, the Fusheng Group started as a business that focused on dismantling and fixing air compressors made by European, American and Japanese manufacturers. During the last 50 years, it has expanded its operations by creating three business units, including machinery (Fusheng Industrial Co., Ltd.), sporting goods (Fusheng Precision Co., Ltd.) and electronics (Fusheng Electronics Corporation).

Among the world’s leading brands of air compressors

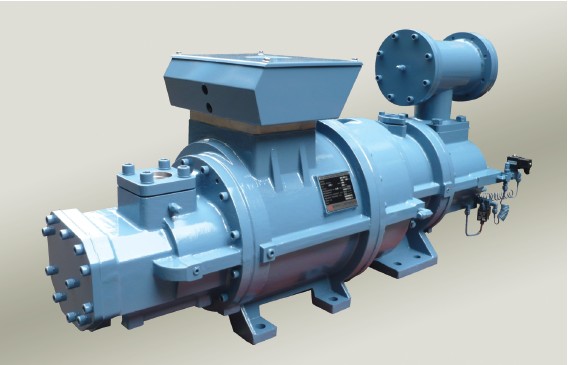

Fusheng Industrial Co., Ltd. designs and manufactures a variety of air compressors, refrigerant compressors and generators, including the company’s highly regarded, Two-Stage Screw Refrigerant Compressor, which won an innovation award from the Taiwan Ministry of Economic Affairs in 2010.

While Fusheng’s air compressors are offered under its private brand, the company also manufactures refrigerant compressors on an original design manufacturer (ODM) basis. In fact, Fusheng ranks No.1 in the Taiwanese air compressor market and is one of the seven largest players in the global air compressor industry.

With its air compressor product line, Fusheng functions as a strong supplier of a variety of reciprocating compressors, scroll compressors, rotary screw compressors and centrifugal compressors – all of which are commonly used in major factories. In addition, Fusheng has the third largest share of the international refrigerant compressor market, selling mainly to chiller producers around the world. These products benefit consumers worldwide in hypermarkets, big-box stores and shopping malls. In these environments, consumers experience the joy of air conditioning, usually without knowing that in many cases, Fusheng compressors made the balmy indoor temperature possible.

During its transformation from a traditional business to a modernized enterprise, Fusheng consistently leveraged the latest information technologies to expand its business territorial reach, improve services and develop higher levels of operational efficiency. All of these tactics are part of the company’s overall strategy for fulfilling its mission as a specialized manufacturer that integrates people, information and technologies, while delivering exceptional customer experiences.

To facilitate this strategy, Fusheng adopted Siemens PLM Software’s Solid Edge® software. James Sun, assistant vice president at Fusheng, explains, “In the year 2000, our company introduced Solid Edge. The implementation fully integrated our design, production, operations and sales organizations, and has revolutionized the efficiency and quality of our overall machinery design process.”

Thinking globally and acting locally – driven by 3D

Fusheng began implementing its global product development and manufacturing initiatives early on, and now owns design centers and factories in Taiwan, China, Southeast Asia, Europe, and the Americas. The company’s need to stay close to its local markets was the primary reason behind its decision to set up international operations.

Fusheng leverages a single, advanced 3D design tool that enables the company to develop all of its products at any and all lifecycle stages, without regard to geographic considerations. Fusheng chose Solid Edge as its computer-aided design (CAD) tool of choice, because it allows the company to think globally and act locally in addressing product design. The company’s deployment of Solid Edge represented a quantum leap in technology for product teams transitioning from 2D design to 3D design. With crystal-clear objectives defined, the transition was quick, efficient and successful.

“Global deployment is what motivated us to go 3D,” says Joseph Liu, manager of Fusheng’s Product Development group. “The Taipei design center took the lead in initially adopting 3D design, which subsequently was introduced to other design centers in other countries. As a result, our use of a single design platform has improved communication among designers and increased our efficiency.”

Fusheng’s management finds Solid Edge to be easier to learn and master than other 3D design software; therefore, many of the capabilities of Solid Edge are highly popular with the company’s designers, as well as directly beneficial to the company’s drive for better design quality. For example, using Solid Edge, Fusheng was able to quickly create user-friendly piping work diagrams, establish a rich and easy-to-use assembly drawing library, and leverage error alerts that enable designers to quickly identify and fix design issues. In addition, the company has been able to virtually eliminate drawing errors.

Measurably better communication, faster to market

Today, Fusheng fully leverages a comprehensive 3D design process for new product development based on Solid Edge. Compared to prior approaches, the use of Solid Edge has dramatically improved the flow of design work, as well as the process for building 3D models.

According to Aaron Lin, who works in the company’s Design group, the ability of Solid Edge to clearly visualize and verify objects in 3D has directly improved communication between Fusheng and its partners. For example, if designers need to send a design drawing from the design center to a factory in order to clarify issues with on-site engineers, they can do so by using a “borrow-program” to present 2D drawings (with isometric view of the 3D model), wherever they are needed.

Lin explains, “We are an ODM for refrigerant compressors, so 3D drawings really facilitate toolingrelated discussions and communication. Today, we send 3D drawings to our in-house design teams, to our partners and even to our clients. We use Solid Edge to send these drawings and clearly present design details, so they can be reviewed, which saves everyone’s time.” He notes, “Solid Edge speeds up production and time-to-market.”

In addition, Fusheng now seamlessly links its design, modeling, assembly, interference checking, back-end computer-aided engineering (CAE) processes, stress analyses, and stressstrain relationship analyses. Liu explains “We use many assembly components in our part drawing process, and we leverage Solid Edge to identify any interferences. As a result, our overall drawings can be made without flaws.”

Solid Edge – instrumental to success

Currently, Fusheng’s core components are processed by the company’s own factories, while other components are made by external partners. According to Liu, the 3D design drawings generated by Solid Edge are leveraged in a variety of ways, including customer specification meetings. In addition, when casting wood patterns, designers use the drawings to communicate the exact mold pattern to the factories, from the start of the design through processing, assembly and even the sales stage.

Ultimately, the company uses 3D design drawings to communicate and collaborate across all stages of product development. As a result, the efficiency and quality of the company’s machinery design process has substantially improved.

Fusheng’s objective is to realize its “local design, local market” strategy and successfully meet the diverse demands of the geographies that it targets. To achieve this goal, individual products often require the use of component designs that originate from multiple design centers. This is where the company’s trans-regional, collaborative design process – thinking globally – comes into the picture.

Looking to the future, company management notes that fulfilling its business maxim – “We strive for your absolute confidence” – is crucial to the organization’s goal of becoming one of the three largest compressor manufacturers in the world. Management notes that Solid Edge is key to realizing its innovation, growth and customer satisfaction goals.

Fusheng Industrial Co., Ltd. designs and manufactures a variety of air compressors, refrigerant compressors and generators, including the company’s highly regarded, Two-Stage Screw Refrigerant Compressor, which won an innovation award from the Taiwan Ministry of Economic Affairs in 2010.

While Fusheng’s air compressors are offered under its private brand, the company also manufactures refrigerant compressors on an original design manufacturer (ODM) basis. In fact, Fusheng ranks No.1 in the Taiwanese air compressor market and is one of the seven largest players in the global air compressor industry.

With its air compressor product line, Fusheng functions as a strong supplier of a variety of reciprocating compressors, scroll compressors, rotary screw compressors and centrifugal compressors – all of which are commonly used in major factories. In addition, Fusheng has the third largest share of the international refrigerant compressor market, selling mainly to chiller producers around the world. These products benefit consumers worldwide in hypermarkets, big-box stores and shopping malls. In these environments, consumers experience the joy of air conditioning, usually without knowing that in many cases, Fusheng compressors made the balmy indoor temperature possible.

During its transformation from a traditional business to a modernized enterprise, Fusheng consistently leveraged the latest information technologies to expand its business territorial reach, improve services and develop higher levels of operational efficiency. All of these tactics are part of the company’s overall strategy for fulfilling its mission as a specialized manufacturer that integrates people, information and technologies, while delivering exceptional customer experiences.

To facilitate this strategy, Fusheng adopted Siemens PLM Software’s Solid Edge® software. James Sun, assistant vice president at Fusheng, explains, “In the year 2000, our company introduced Solid Edge. The implementation fully integrated our design, production, operations and sales organizations, and has revolutionized the efficiency and quality of our overall machinery design process.”

Thinking globally and acting locally – driven by 3D

Fusheng began implementing its global product development and manufacturing initiatives early on, and now owns design centers and factories in Taiwan, China, Southeast Asia, Europe, and the Americas. The company’s need to stay close to its local markets was the primary reason behind its decision to set up international operations.

Fusheng leverages a single, advanced 3D design tool that enables the company to develop all of its products at any and all lifecycle stages, without regard to geographic considerations. Fusheng chose Solid Edge as its computer-aided design (CAD) tool of choice, because it allows the company to think globally and act locally in addressing product design. The company’s deployment of Solid Edge represented a quantum leap in technology for product teams transitioning from 2D design to 3D design. With crystal-clear objectives defined, the transition was quick, efficient and successful.

“Global deployment is what motivated us to go 3D,” says Joseph Liu, manager of Fusheng’s Product Development group. “The Taipei design center took the lead in initially adopting 3D design, which subsequently was introduced to other design centers in other countries. As a result, our use of a single design platform has improved communication among designers and increased our efficiency.”

Fusheng’s management finds Solid Edge to be easier to learn and master than other 3D design software; therefore, many of the capabilities of Solid Edge are highly popular with the company’s designers, as well as directly beneficial to the company’s drive for better design quality. For example, using Solid Edge, Fusheng was able to quickly create user-friendly piping work diagrams, establish a rich and easy-to-use assembly drawing library, and leverage error alerts that enable designers to quickly identify and fix design issues. In addition, the company has been able to virtually eliminate drawing errors.

Measurably better communication, faster to market

Today, Fusheng fully leverages a comprehensive 3D design process for new product development based on Solid Edge. Compared to prior approaches, the use of Solid Edge has dramatically improved the flow of design work, as well as the process for building 3D models.

According to Aaron Lin, who works in the company’s Design group, the ability of Solid Edge to clearly visualize and verify objects in 3D has directly improved communication between Fusheng and its partners. For example, if designers need to send a design drawing from the design center to a factory in order to clarify issues with on-site engineers, they can do so by using a “borrow-program” to present 2D drawings (with isometric view of the 3D model), wherever they are needed.

Lin explains, “We are an ODM for refrigerant compressors, so 3D drawings really facilitate toolingrelated discussions and communication. Today, we send 3D drawings to our in-house design teams, to our partners and even to our clients. We use Solid Edge to send these drawings and clearly present design details, so they can be reviewed, which saves everyone’s time.” He notes, “Solid Edge speeds up production and time-to-market.”

In addition, Fusheng now seamlessly links its design, modeling, assembly, interference checking, back-end computer-aided engineering (CAE) processes, stress analyses, and stressstrain relationship analyses. Liu explains “We use many assembly components in our part drawing process, and we leverage Solid Edge to identify any interferences. As a result, our overall drawings can be made without flaws.”

Solid Edge – instrumental to success

Currently, Fusheng’s core components are processed by the company’s own factories, while other components are made by external partners. According to Liu, the 3D design drawings generated by Solid Edge are leveraged in a variety of ways, including customer specification meetings. In addition, when casting wood patterns, designers use the drawings to communicate the exact mold pattern to the factories, from the start of the design through processing, assembly and even the sales stage.

Ultimately, the company uses 3D design drawings to communicate and collaborate across all stages of product development. As a result, the efficiency and quality of the company’s machinery design process has substantially improved.

Fusheng’s objective is to realize its “local design, local market” strategy and successfully meet the diverse demands of the geographies that it targets. To achieve this goal, individual products often require the use of component designs that originate from multiple design centers. This is where the company’s trans-regional, collaborative design process – thinking globally – comes into the picture.

Looking to the future, company management notes that fulfilling its business maxim – “We strive for your absolute confidence” – is crucial to the organization’s goal of becoming one of the three largest compressor manufacturers in the world. Management notes that Solid Edge is key to realizing its innovation, growth and customer satisfaction goals.