Fronius committed to China's advanced manufacturing

Fronius, an Austrian company specializing in welding technology, is eyeing its market prospects in China, according to a senior executive.

Zhang Ming, managing director of Fronius Intelligent Equipment China, the wholly-owned subsidiary of Fronius International GmbH, said China has rolled out a series of policies to promote the development of advanced machinery and intelligent manufacturing, which is conducive to the industry's high-quality development.

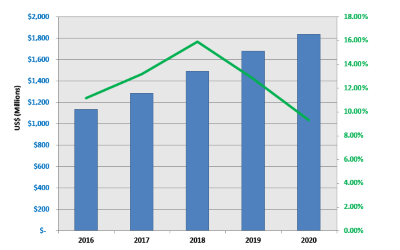

The industry has enormous growth potential. Forward Industry Research Institute forecasts in a report that the sector will have a market size surpassing 300 billion yuan ($45.98 billion) in 2024.

"As intelligent production is the trend of the times, the machines and equipment that enable the intelligentization of manufacturing are key to keeping up with that," Zhang said.

Fronius International GmbH, which evolved from a simple one-man repair and maintenance operation founded in 1945, has grown into an integral part of the global industrial landscape.

The company specializes in providing high-quality welding systems and solutions. In addition, its business portfolio has also expanded into the other sectors of solar energy and charging equipment.

It ships exports to more than 70 countries and regions, and are widely used in a variety of sectors that require welding, such as auto manufacturing, rail transport, aviation and space, construction machinery, energy and chemicals.

The family-run business, which has passed through three generations, has valued technological progress as its core competitiveness all throughout its growth and has been pioneering industrial innovation.

With more than 500 experts in research and development, the Austria-based company has accumulated strong technological expertise in welding technology over the past decades and owns over 900 valid invention patents.

Back in 1981, Fronius developed the world's first primary transistor-based inverter power source, which significantly reduced a welding machine's size and weight.

In 1998, the world's first fully digitally-controlled TPS power source was created at the company. The invention led to a digital revolution in the welding industry and enabled the sector to embark on a digitalization era featuring precise control.

In 2001, the company introduced the first laser-arc hybrid welding system to the industry.

The cold metal transfer technology developed by Fronius in 2005 was a milestone in the industry, as it enabled thin materials to be easily welded, and aluminum and steel joined for the first time — a unique selling point on the market for many years.

In 2013, the company launched the first intelligent welding system TPS/i, opening a new chapter in intelligent welding.

The system features many leading-edge technologies, improving automation and reducing human interference.

In 2014, Fronius produced the first portable power supply for manual metal arc welding.

With its products targeting high-end, advanced and sophisticated manufacturing sectors, Fronius aims to promote intelligent, efficient and high-quality production, Zhang said.

"We are devoted to providing our customers with a full range of intelligent welding solutions, satisfying them with improvements to our technologies and winning their hearts and word-of-mouth by addressing their needs to increase their output and reduce the rejection rate of products."

This year marks the 50th anniversary of establishing diplomatic relations between China and Austria.

As a shining example of Austrian business, Fronius has a close bond with China. It entered the Chinese market in 1998 and established its only wholly-owned subsidiary on the Chinese mainland — Fronius Intelligent Equipment China, also known as Fronius China — in Shanghai in 2011.

Fronius China moved into a robotic industrial park in the metropolis in East China in 2018 and won the title of the city's high-tech business a year later.

East China, one of the most economically dynamic regions that has a friendly climate for opening-up, is one of the company's key markets in the country, as the region has attracted a host of advanced manufacturers from home and abroad, Zhang said.

With the COVID-19 pandemic well under control in China, the country has witnessed an extensive recovery in its economy. Thus the demand from the advanced manufacturing sector in the East China region for Fronius products is still on the rise, he noted.

Fronius China has established branches in Tianjin, Wuhan, Guangzhou and Chongqing, and its service network has expanded into different regions, according to the company.