Six Must-Have Elements of Full-Scale Digital Product Lifecycle Management

Move away from physical product management into rapid-action product digitalization at every stage of product development.

What is Digital PLM?

It’s increasingly challenging for R&D departments to operate a cost-effective product lifecycle when product data is manually gathered, stored and analyzed across working groups and formats--and rarely consolidated into one place.

To complete product research and cost-effectively test new and updated products, R&D scientists often are stuck “data wrangling” product attributes throughout the organization and manually completing formula calculations in Excel lookup tables- modeling different product scenarios with multiple variables which are incredibly time-consuming.

Companies are on the hunt for ways to completely digitalize every stage of product development and put predictive models in place that can automatically determine the best chance of a product’s success.

Digital PLM refers to the ability to:

It’s a direct shift not just away from manual processes, but a totally new world of how internal systems and data can be combined and analyzed for more competitive and cost-effective decision-making. In fact, many companies are anticipating a day when their R&D departments can totally bypass lab trials or sample development and complete testing in an entirely digital system.

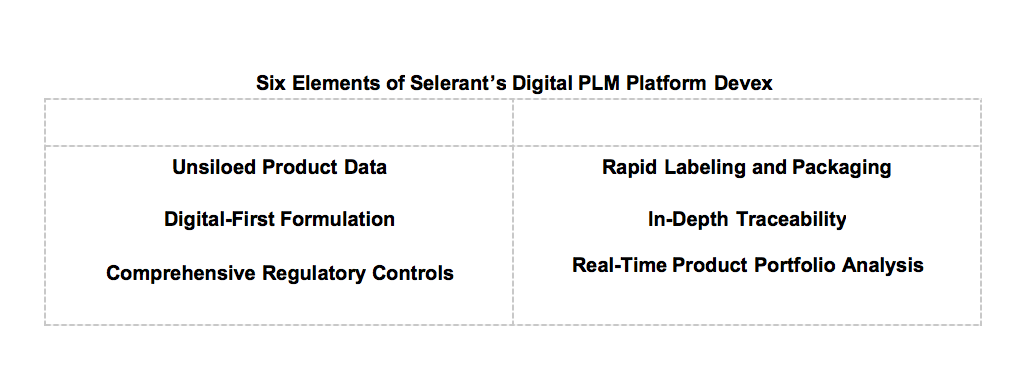

How Does Devex Facilitate Digital PLM?

Selerant’s formula-based PLM system Devex helps companies achieve a “single point of truth” in product data with both sophisticated digital formulation tools and visual interfaces that make it possible to analyze the product lifecycle, from ideation to finished product, in one system.

Most PLM systems have the ability to manage associated product properties, but many do not enable users to perform real-time data simulations, design of experiments or run what-if formulation simulations. By formatting product data within formula-based PLM process tools, Selerant’s digital PLM platform Devex enables companies to unearth new business insights and leverage product analysis to rapidly test, model and execute different scenarios.

Unsiloed Product Data

Digitalization of the product life cycle begins with uncoupling product assets from the various systems and groups in which they live into a digital PLM system. In the Devex PLM system, supplier data, product information and cost data are all accessible as data objects in one system and can be used in multi-layered formulas and calculations, no matter their original format or use, to:

Selerant’s robust digital data management tools make it the central system not just for accessing and viewing product data, but sharing it across the enterprise and supply chain for more effective collaboration.

Digital-First Formula Calculations

With digital PLM, R&D departments can simulate experiments and trials on how different product attributes might impact it’s composition prior to physical lab testing or pilot plant trials, leading to more informed and economical decision-making

The Formulation Tool in Devex makes it possible to track product properties against predetermined ranges for cost, sensory, physical & chemical properties and much more prior to testing or sample creation. Research teams can find the best combination of ingredients that meet all product attributes and specific regulatory requirements prior to any trial testing, significantly shortening research and development timelines.

This easy, intuitive interface for viewing formula modifications, approvals, activations and related data points creates a chronological digital snapshot of product development that cannot be easily created when using physical means or disparate systems to manage product changes.

Rapid Labeling and Packaging

With digital PLM, product teams can quickly see how product formulation affects labeling requirements, and easily modify formula data to fit different labeling formats.

Devex PLM contains an express ingredient statement tool that provides the ability to quickly and easily create an ingredient label in one step by:

By including labeling needs and data objects in a digital PLM system, product labels can be created in one system with more accuracy and less time.

Comprehensive Regulatory Control

Regulatory teams have the difficult task of assessing risk based on the markets the products will be sold. Digital PLM provides “baked in” data parameters for compliance to help R&D and regulatory teams make sure legal ranges for product elements are met at the very beginning of product planning to all the way through when the product is commercialized.

Devex PLM automates the ability to compare how product decisions stake up against intricate regulatory requirements at every stage of product development.

Ensuring comprehensive compliance throughout product design is only possible when

Perform Digital Traceability Across Product Lines

All arms of process-focused companies, from Research & Development, Compliance, Product and Innovation teams, must all be able to respond quickly together to upcoming regulatory changes or compromised supply chains. Using a digital PLM system introduces a preventative rather than reactionary model of traceability.

Devex’s digital PLM software provides complete tools for researching and answering internal and external questions around product integrity, ratios and regulated product attributes.

With Selerant’s Devex, regulatory and product teams can easily find and implement changes into multiple products at once, without manual searching and updating.

These traceability tools bring a preventative rather than reactionary model of traceability that saves time, operational costs and compliance risks.

Product Portfolio Management & Analysis

Beyond the routine steps of product development, digital PLM’s data consolidation also opens the door for better control and insight into product innovation. Companies can maximize the product investments with more direct insight into the project pipeline and new opportunities and risks.

Devex’s Innovation Process Management Suite (IPMS) allow companies to see portfolio performance in real-time and dedicate the right internal resources to the most high-value projects or ideas with:

Combining product, financial and personnel data drives more accurate and responsive decision-making that fans across at all levels of the organization.

Benefits of Selerant’s Digital PLM Platform Devex

Devex 3.6 brings the ability to connect the R&D process with better data integrity, complete faster and more accurate experiments and trials, and communicate and review control points throughout the product life cycle.

Companies that use Devex 3.6 to streamline product development and leverage digital data across the product life cycle will:

Get started today with a demo of the Devex digital PLM system.

It’s increasingly challenging for R&D departments to operate a cost-effective product lifecycle when product data is manually gathered, stored and analyzed across working groups and formats--and rarely consolidated into one place.

To complete product research and cost-effectively test new and updated products, R&D scientists often are stuck “data wrangling” product attributes throughout the organization and manually completing formula calculations in Excel lookup tables- modeling different product scenarios with multiple variables which are incredibly time-consuming.

Companies are on the hunt for ways to completely digitalize every stage of product development and put predictive models in place that can automatically determine the best chance of a product’s success.

Digital PLM refers to the ability to:

- Manage product planning, trial, formula, specification, packaging and regulatory decisions in an entirely digital environment.

- Complete most of the product lifecycle steps from product planning, research, development, production and risk analysis in one system.

- Analyze product lines and portfolios with comprehensive data analysis not possible without interconnected systems and processes.

- Leverage real-time data access from across interconnected devices, sensors, external systems, open portals for consumer inputs and feedback and other departments to drive product innovation decisions.

- Rapidly speed up time to market with more informed research and trial testing.

It’s a direct shift not just away from manual processes, but a totally new world of how internal systems and data can be combined and analyzed for more competitive and cost-effective decision-making. In fact, many companies are anticipating a day when their R&D departments can totally bypass lab trials or sample development and complete testing in an entirely digital system.

How Does Devex Facilitate Digital PLM?

Selerant’s formula-based PLM system Devex helps companies achieve a “single point of truth” in product data with both sophisticated digital formulation tools and visual interfaces that make it possible to analyze the product lifecycle, from ideation to finished product, in one system.

Most PLM systems have the ability to manage associated product properties, but many do not enable users to perform real-time data simulations, design of experiments or run what-if formulation simulations. By formatting product data within formula-based PLM process tools, Selerant’s digital PLM platform Devex enables companies to unearth new business insights and leverage product analysis to rapidly test, model and execute different scenarios.

Unsiloed Product Data

Digitalization of the product life cycle begins with uncoupling product assets from the various systems and groups in which they live into a digital PLM system. In the Devex PLM system, supplier data, product information and cost data are all accessible as data objects in one system and can be used in multi-layered formulas and calculations, no matter their original format or use, to:

- Send and gather supplier questionnaires data and directly incorporate a digital specification to your purchased raw materials and blends with a dedicated Supplier Collaboration Portal.

- Use digital formula, specification, material master and label templates that contain fields for product data gathered through devices, sensors,research, legislative sources and from other validated data sources

- Automatically integrate ERP data into the product lifecycle, tying accounting processes to product development

- Set and digitally notify product approvers and reviewers, enabling rapid collaboration and information access across departments at every step of product development.

Selerant’s robust digital data management tools make it the central system not just for accessing and viewing product data, but sharing it across the enterprise and supply chain for more effective collaboration.

Digital-First Formula Calculations

With digital PLM, R&D departments can simulate experiments and trials on how different product attributes might impact it’s composition prior to physical lab testing or pilot plant trials, leading to more informed and economical decision-making

The Formulation Tool in Devex makes it possible to track product properties against predetermined ranges for cost, sensory, physical & chemical properties and much more prior to testing or sample creation. Research teams can find the best combination of ingredients that meet all product attributes and specific regulatory requirements prior to any trial testing, significantly shortening research and development timelines.

- Automatically calculate multi-layer formulas with roll-up data based on product attributes and specifications.

- Quickly model the output of different product trials, whether comparing cost outputs or experimenting with different base percentages within multi-layered formulas.

- Optimize formulas on the fly without any manual calculations or data mining between systems.

- Digitally model the best ingredient combination to achieve a target cost ceiling.

- See the entire history of formula with Formula TImeline View, connecting specifications and multi-layered formulas with related documentation.

This easy, intuitive interface for viewing formula modifications, approvals, activations and related data points creates a chronological digital snapshot of product development that cannot be easily created when using physical means or disparate systems to manage product changes.

Rapid Labeling and Packaging

With digital PLM, product teams can quickly see how product formulation affects labeling requirements, and easily modify formula data to fit different labeling formats.

Devex PLM contains an express ingredient statement tool that provides the ability to quickly and easily create an ingredient label in one step by:

- Visually creating product labels based on changing product data without physical production.

- Digitally capture and classify data for country-specific label requirements.

- Automatically round or change exact formula numbers for various label formats.

- Displaying dates of manufacturing

- Connecting labels specifications with related material and formula specifications.

By including labeling needs and data objects in a digital PLM system, product labels can be created in one system with more accuracy and less time.

Comprehensive Regulatory Control

Regulatory teams have the difficult task of assessing risk based on the markets the products will be sold. Digital PLM provides “baked in” data parameters for compliance to help R&D and regulatory teams make sure legal ranges for product elements are met at the very beginning of product planning to all the way through when the product is commercialized.

Devex PLM automates the ability to compare how product decisions stake up against intricate regulatory requirements at every stage of product development.

- Set and calculate against compliance targets for base percentages in formula, material, and label specification product data objects.

- Automatically connect to Selerant’s Compliance Cloud, a centralized system of food regulatory and safety knowledge.

- Set threshold parameters for material master product attributes

- Digitally manage the creation and submission of custom service documents for different country registrations

- Create detailed compliance and product reports on activity around every stage of the product life cycle.

Ensuring comprehensive compliance throughout product design is only possible when

Perform Digital Traceability Across Product Lines

All arms of process-focused companies, from Research & Development, Compliance, Product and Innovation teams, must all be able to respond quickly together to upcoming regulatory changes or compromised supply chains. Using a digital PLM system introduces a preventative rather than reactionary model of traceability.

Devex’s digital PLM software provides complete tools for researching and answering internal and external questions around product integrity, ratios and regulated product attributes.

With Selerant’s Devex, regulatory and product teams can easily find and implement changes into multiple products at once, without manual searching and updating.

- A fully-digital exchange compliance data between suppliers, customers, regulatory agencies and internal stakeholders

- The ability to quickly facilitate process standardization and best practices across all internal and external teams involved with

- Digital creation of statement lists of all product attributes and where they reside within product lines.

- Instant searching and identification all formulas affected by product changes driven by new regulations or compromised supply chains.

- The ability to digitally update multiple, multi-assortment formulas in response to changing standards .

These traceability tools bring a preventative rather than reactionary model of traceability that saves time, operational costs and compliance risks.

Product Portfolio Management & Analysis

Beyond the routine steps of product development, digital PLM’s data consolidation also opens the door for better control and insight into product innovation. Companies can maximize the product investments with more direct insight into the project pipeline and new opportunities and risks.

Devex’s Innovation Process Management Suite (IPMS) allow companies to see portfolio performance in real-time and dedicate the right internal resources to the most high-value projects or ideas with:

- Visual overviews of the entire product portfolio in a few keystrokes.

- Mobile product, resources and multi-project dashboards and status reports, accessible everywhere, at any time.

- Real-time collaboration and optimized teamwork

- Workflow and tasks management options with instant notifications to team members at significant project evolution points.

- Configurable project templates with business case definitions.

Combining product, financial and personnel data drives more accurate and responsive decision-making that fans across at all levels of the organization.

Benefits of Selerant’s Digital PLM Platform Devex

Devex 3.6 brings the ability to connect the R&D process with better data integrity, complete faster and more accurate experiments and trials, and communicate and review control points throughout the product life cycle.

Companies that use Devex 3.6 to streamline product development and leverage digital data across the product life cycle will:

- Significantly reduce production costs and time to market.

- Complete more accurate trial formulas.

- Easily create more detailed labeling specifications to meet new consumer safety concerns.

- Automatically connect product data fine-tuned in research and development into label specifications.

- More confidently manage and hit changing regulatory targets in products across industries and geographies. Connect compliance standards directly to supplier data and source ingredients and integrate it into digital formula objects and manufacturing processes.

- Reduce the costs of traceability with transparency into every aspect of product development.

Get started today with a demo of the Devex digital PLM system.